Binciken Kan Ni-Si Alloy Slender Shaft Juya Fasaha

Binciken Kan Ni-Si Alloy Slender Shaft Juya Fasaha

|

Nickel-silicon alloy ne na hali high-zazzabi gami. Abu ne mai wuyar sarrafawa kuma ana amfani dashi sosai a sararin samaniya, jiragen sama da sauran fagage. Yanke shi abu ne mai wahala a fasahar kere kere ta zamani. Haɗu da sifofin abubuwan da ke tattare da siliki na nickel-silicon alloy, ɗaukar abokan hulɗa na kamfanin nickel-silicon alloy a matsayin misali, an yi nazarin fasahar sarrafa juyi, kuma an tanadar da wata fasahar sarrafa kayan gawa mai zafi don taron, wanda ke da takamaiman aiki. ƙimar aikace-aikacen. |

1. Gabatarwa

Haɗaɗɗen zafin jiki kuma ana kiran alloys masu jure zafi ko ƙarfin zafi. Yana da wani hadadden Multi-bangaren gami bisa baƙin ƙarfe, nickel, cobalt, titanium, da dai sauransu, kuma zai iya aiki a karkashin high zafin jiki hadawan abu da iskar shaka yanayi da kuma iskar gas yanayi na 600 ~ 1000 ℃. Bugu da ƙari, yana iya yin aiki na dogon lokaci a ƙarƙashin wasu damuwa, kuma yana da kyakkyawan ƙarfin zafi, kwanciyar hankali na thermal da aikin gajiyar thermal.

Duk da haka, high-zazzabi alloys ne hankula wuya-to-yanke kayan, tare da taurin sama da 250HBS, ƙarfi σb>0.98GPa, elongation δ> 30%, tasiri darajar ak> 9.8 × 105J / m2, thermal conductivity k<41.9W / (m2 ℃) , High zafin jiki juriya kai tsaye ƙara wahalar aiki. A ƙarƙashin aikin haɗin gwiwar babban ƙarfin yankewa da zafin jiki mai zafi yayin aiki, kayan aiki yana haifar da gutsuttsura ko nakasawa, sannan kuma ya karya; Bugu da kari, irin wannan gami zai hanzarta samar da aikin hardening sabon abu, da kuma workpiece za a samar a lokacin aiki. Ƙarƙashin ƙaƙƙarfan kayan aiki zai haifar da ƙaddamar da kayan aiki don samar da raguwa a cikin zurfin yanke, kuma ya haifar da damuwa maras so a kan kayan aiki, kuma ya lalata daidaiton geometric na sassa na inji.

2. Binciken halin da ake ciki yanzu

Masanan kasashen waje sun yi bincike da yawa a kan yankan superalloys. A cikin 1939, Kamfanin British Mond Nickel Company (Kamfanin Nickel na Duniya) ya fara haɓaka gami da Nimonic 75 na tushen nickel, sannan aka yi nasarar amfani da Nimonic 80 a cikin kayan injin turbojet, wanda ya samar da jerin gami da Nimonic na tushen nickel. A farkon 1940, {asar Amirka ta ƙera Hastelloy B nickel-based alloy don amfani da injin jet na GE's Bellp-59. A cikin 1950, Kamfanin PW na Amurka, Kamfanin GE da Kamfanin Ƙarfe na Musamman sun haɓaka Waspalloy, M-252 da Udmit 500 alloys bi da bi, kuma sun kafa Inconel, Mar-M da Udmit a kan wannan tushen, waɗanda ake amfani da su sosai a cikin injin turbine. . Daga 1940 zuwa tsakiyar 1950, da gami abun da ke ciki da aka gyara. 1950: Fitowar injin narkewar fasaha ya ba da damar haɓaka babban adadin manyan abubuwan da suka dace na simintin gyare-gyare irin su Mar-M200 da A cikin 100. Bayan 1960, haɓaka sabbin hanyoyin aiwatarwa kamar ƙarfi na shugabanci, gami da kristal guda ɗaya. foda metallurgy, inji alloying, da yumbu tacewa isothermal ƙirƙira sun zama babban motsa jiki don haɓaka superalloys. Haka nan malaman cikin gida ma sun yi bincike da yawa. Daga 1956 zuwa 1957, GH3030, GH4033, GH34 da K412 alloys an yi nasarar yin gwajin gwaji don injunan WP-5; a cikin 1960, GH4037, GH3039, GH3044, GH4049, GH3128, K417 da sauran allunan da aka yi a jere-gwaji. Ci gaba cikin nasara; Hakanan a jere ya ƙera rukunin superalloys don injunan roka daban-daban; A lokaci guda kuma, an fara yin amfani da manyan allunan da ake amfani da su a fannonin masana'antu na farar hula, kamar injinan dizal, injin iskar gas, da dai sauransu, an kuma samar da wani nau'i na alluna masu jure zafin jiki daya bayan daya. Abrasion da lalata-resistant superalloys; a cikin 1970, samar da gwaji da bincike na superalloys sun fara yin tsari. Ta hanyar kwaikwayo, narkewa da ci gaban Soviet superalloys a matsayin babban gami da ingancin tsarinsa, ya kai ko wuce matsayin Soviet da ainihin matakin. Duk kayan da ake buƙata don injin suna cikin China.

A halin yanzu, kamfanin masu haɗawa kuma relays ba su da ƙwanƙolin zafin jiki mai zafi. Suzhou Huatan yana samar da Halliburton kuma galibi yana aiwatar da allurai masu zafi. Sashen Samfur na Guiyang yana da alhakin yanke sigogi, kayan aikin kayan aiki da kusurwoyi, sanyaya da lubrication, da kayan aiki yayin sarrafa kayan gami masu zafi. Binciken na yau da kullun game da aiki bai isa ba, kuma ana buƙatar bincike na tsari akan sarrafa kayan gami da zafin jiki don aza harsashin samar da babban aiki mai yawa. masu haɗawa zuwa gaba. Don haka, akwai bukatar a gaggauta gudanar da bincike kan fasahar sarrafa gawa mai zafi don biyan ainihin bukatun samar da bitar.

3. Binciken tsarin sashi

sassan jikin allura na siriri shasha yana buƙatar ƙarfin injina mai ƙarfi da juriya mai ƙarfi a babban zafin jiki. Jimlar tsawon jikin allura shine 32mm, kuma diamita suna bi da bi φ1.2mm, φ1.5mm, da φ1.58mm, waɗanda ke cikin siriri. shasha sassa. , Yana da sauƙi don lalatawa yayin aiki, kuma ana buƙatar sarrafa nakasar don biyan bukatun samarwa.

4. Zaɓin kayan aiki

Tun da aiki na nickel-silicon gami na bukatar high taurin, m texture, mai kyau zafi canja wurin sakamako, da kuma karfi high zafin jiki aiki, musamman a 600 ℃, shi zai samar da wani m bayani tare da oxygen da nitrogen. Lokacin sarrafa gami da nickel-silicon, taurin saman zai karu sosai. Yana da tasirin abrasion mai ƙarfi. Saboda juriya da juriya da zafin jiki na kayan aikin da aka rufe, ya kamata a yi amfani da kayan aikin rufewa gwargwadon yadda zai yiwu yayin sarrafa irin waɗannan sassan gami da zafin jiki.

Kayan aikin carbide da aka yi da siminti kusan sun dace da yankan nau'ikan nau'ikan kayan injin da ke da wuyar gaske, amma aikin da aka yi da rufin (rufi guda ɗaya da mai haɗawa) ya bambanta sosai. Sabili da haka, ya kamata a zaɓi sutura masu dacewa bisa ga kayan aiki daban-daban kayan aiki kayan aiki. Carbide mai lu'u-lu'u mai lu'u-lu'u da kuma DLC (Diamond Kamar Carbon) mai rufin siminti mai rufi yana ƙara haɓaka kewayon aikace-aikacen kayan aikin da aka rufa, kuma a makance zaɓi sabbin ruwan wukake na kayan aiki daga ainihin bukatun sarrafawa, wanda kuma yana iya haɓaka farashin sarrafawa da amfani da sabbin kayan Lokacin shigar da ruwa. , Idan saurin yankewa da ƙimar ciyarwa ba daidai ba ne, kuma zai shafi ingancin kayan aiki da rayuwar sabis na kayan aiki. Sabili da haka, lokacin zabar abubuwan da ake sakawa don kayan injin mai wahala, ya zama dole don kimanta tattalin arziƙin sarrafawa daidai kuma la'akari da duk tsarin sarrafawa gabaɗaya.

Dangane da nazarin zaɓin kayan aiki, wannan labarin ya zaɓi Kyocera na musamman kayan aikin nickel gami da Sandvik na musamman na nickel gami don sarrafa gwaje-gwaje. Ana nuna aikin kayan aikin yankan a cikin Table 1.

|

sunan |

Samfurin samfurin |

Tip kusurwa |

Tukwici R |

Material |

shafi |

|

Kyocera Cylindrical Knife |

Saukewa: VBGT110301R-F |

35 ° |

0.1 |

PR930: Ultrafine barbashi tushe abu |

TICN (PVD) |

|

Sandvik Cylindrical Knife |

Saukewa: VCGT110301-UM1125 |

35 ° |

0.1 |

GC1125: Kayan da aka yi amfani da shi don buƙatun ƙarfin ƙarfi |

TICN (PVD) |

5. Binciken yanke ruwa

Ruwan yankan na iya zama ruwan yankan tushen ruwa, wanda ke da saurin canja wuri mai zafi da ruwa mai kyau. Ba zai yiwu a yi amfani da ruwan yankan mai ɗauke da chlorine ba. Ba za a iya haɗa shi da aluminum, zinc da abubuwan haɗin sa, jan ƙarfe da tin yayin sarrafawa ba. Idan ruwan yankan ya ƙunshi Chlorine zai bazu kuma ya saki hydrogen a yanayin zafi mai zafi yayin aikin yankan, wanda zai haifar da kumburin epidermal bayan an shafe shi da nickel, kuma yana iya haifar da lalatawar yanayin zafi mai zafi na nickel gami.

Ruwan yankan bitar galibi yana amfani da alamar Flowserve, samfurin ECOCOOL EM5 wani ruwan yankan ruwan fari ne mai narkewa da ruwa mai narkewa, kuma ana nuna nau'in sinadaransa a cikin tebur 2. Ana iya gani daga tebur 2 cewa wannan ruwan yankan ruwa ne. Babban bangaren shine man fetur na ma'adinai, ba ya ƙunshi chlorine, kuma ya dace da bukatun machining nickel alloys. Wannan ruwan yankan na iya biyan bukatun nickel kayan aikin gami.

6.Gibbscam software shirye-shirye

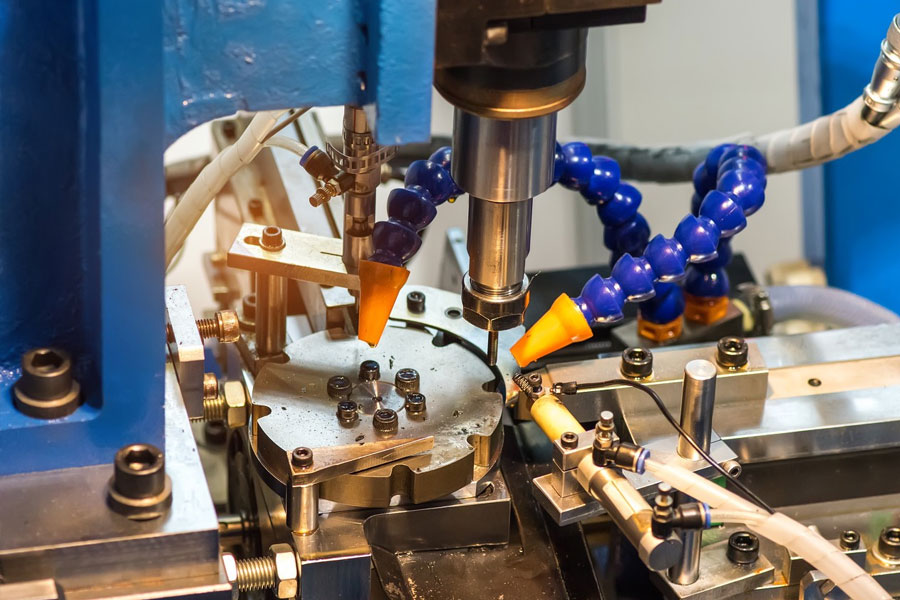

GibbsCAM software ce ta CAM don sassan cnc machining, musamman hanyoyin sarrafa CAM a fagen juyawa da niƙa. Baya ga juyi da niƙa, yana kuma goyan bayan 2-axis zuwa 5-axis milling, juyawa, haɗa kayan aikin niƙa da yawa da yankan waya. Babban fasalinsa shine taƙaitaccen mu'amalarsa, mai sauƙin koya da amfani, kuma yanayin aiki ya yi daidai da halayen sana'ar mu. Ya shiga kasuwar kasar Sin a watan Yunin 2008. Kamfaninmu ya sayi manhajar a watan Yulin 2009. Ana amfani da ita ne a cikin jujjuyawar dijital na kamfanin, injin niƙa na dijital, kayan aikin jujjuyawar niƙa da cibiyoyin injin axis biyar. Irin wannan kayan aiki yana da juyi, niƙa, da hakowa. , Boring, broaching (ramuka) da sauran ayyuka, tare da X, Y, Z, C, E da Axes. Ana iya amfani da software na CAM don kowane haɗin axis da yawa don gane sarrafa sassa daban-daban. Tare da bambance-bambancen da rikitarwa na sabbin sassa, yana da mahimmanci a yi amfani da software na shirye-shirye don shirye-shiryen NC. Ana nuna hanyar kayan aiki na sashin siriri mai siririn a hoto na 4.

7. Juya aikin tabbatarwa bincike

Tun da slitting atomatik juya nasa ne daya-yanke juya a wuri, da yankan karfi ne babba, wanda ya sa sassa da za a iya sauƙi nakasassu da kuma surface ingancin ba shi da kyau. Wajibi ne a bincika kowane bangare, gyara bambance-bambancen lokaci, da canza sigogin shirin da diyya na kayan aiki. A lokaci guda, saboda kayan aiki na atomatik yankan mota ta atomatik, kayan aikin ba ya raba mashin ɗin da kyau, kuma ana sarrafa duk daidaiton ma'auni a cikin wucewa ɗaya, don haka ana sanya buƙatu mafi girma akan aikin kayan aiki.

Lokacin yankan nickel-chromium-nickel-silicon alloy, yankan zafin jiki yana da girma, ƙarfin kayan aiki yana da ƙasa, kuma saurin yanke yana da tasiri mafi girma akan yankan zafin jiki. Gabaɗaya, simintin carbide kayan aikin ana kiyaye shi a 650 ℃~750 ℃. Ta hanyar gwaje-gwajen juyi da yawa, ana samun waɗannan sigogi masu zuwa:

1) Yanke gudun vc

Gudun yankan yana da tasiri mafi girma akan dorewa na kayan aiki. Zai fi dacewa don saita saurin yankewa a ƙarƙashin yanayin ƙarancin lalacewa na kayan aiki. Ana iya saita shi bisa ga taurin da yanke zurfin kayan yanka daban-daban. Yi ƙoƙarin zaɓar ƙananan saurin yanke don aiwatar da gami da nickel. Gabaɗaya, niƙa mai tauri shine 20-50m/min, kuma niƙa mai kyau shine 40-70m/min;

2) Adadin ciyarwa f

Yawan ciyarwar yana da ɗan tasiri akan dorewar kayan aiki. A cikin yanayin tabbatar da rashin ƙarfi na na'ura, za'a iya zaɓar ƙimar abinci mafi girma. Gabaɗaya, ana iya zaɓar 0.003 ~ 0.006mm/r, kuma ƙimar ciyarwar ba zai iya zama babba ba. Da yawa zai sa kayan aiki su sa kayan aiki da sauri, ƙara ƙarfin yankewa, da haifar da lalacewa na sassa. Saboda haka, gabaɗaya bai kamata ya zama mafi girma fiye da 0.006 mm/r;

3) Zurfin yanke ap

Zurfin yankan yana da ƙarancin tasiri akan ƙarfin kayan aiki. Gabaɗaya, za'a iya amfani da zurfin zurfin yankewa da farko, wanda zai iya hana tip ɗin kayan aiki daga yankewa a cikin Layer mai tauri, kuma yana iya ƙara tsayin aiki na gefen kayan aiki, wanda ke da amfani ga zubar da zafi. Haƙuri mai girma, zurfin yanke daidai yake da ƙarancin ƙarancin girman ɓangaren, kuma ba za a iya daidaita shi da hannu ba.

Ta hanyar yin amfani da Kyocera na musamman na nickel alloy da kuma Sandvik na musamman na nickel alloy don tabbatarwa, ɓangaren cnc machining yana nunawa a cikin Figures 5 da 6. Sakamakon farfajiyar sassan yana da kyau, kuma kayan aiki ba shi da wani lalacewa; rashin daidaituwa na sassan da aka sarrafa ta Sandvik ruwan wukake yana da girma, wanda ba zai iya biyan bukatun zane-zane ba. Saboda haka, ana amfani da ruwan wukake na Kyocera don madauwari na waje. Idan ana buƙatar gyara alama, an fi son ruwan wukake na Kyocera.

8. Summary

Nufin matsalar cewa nickel-chromium-nickel-silicon alloy lambobin sadarwa ba su da ikon aiwatarwa, wannan labarin yana farawa daga bangarorin kayan aiki da sigogin tsari, yana gudanar da gwaje-gwajen tsari da yawa, ya sami kayan aikin da ya dace da nickel-chromium- nickel-silicon alloy aiki, yana inganta sigogin sarrafawa, kuma yana magance matsalar. Domin magance matsalar sarrafa sinadarin nickel-chromium-nickel-silicon alloy, taron ya sami damar sarrafa kayan daga rashin iya sarrafa su. A karo na farko, yana da ikon sarrafa kayan nickel-chromium-nickel-silicon alloy kayan aiki, wanda ke inganta ingantaccen aiki da ingancin cnc na sassa. Batch samar da gami lambobin sadarwa aza harsashi.

Shiga wannan labarin : Binciken Kan Ni-Si Alloy Slender Shaft Juya Fasaha

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan