Zaɓi Da Zane Na Hanyar Rarraba Manipulator

Zaɓi Da Zane Na Hanyar Rarraba Manipulator

|

A cikin tsarin ƙira na mai amfani, akwai zaɓuɓɓuka da yawa don hanyoyin kamawa. Wace irin hanyar kamawa don zaɓar, ban da la'akari da tsarin, ya fi game da farashin amfani da saukin kulawa. Yi la'akari, bayan komai, abu mai kyau yana buƙatar la'akari da farashi mai inganci. |

1. Haɗaɗɗen ruwa da kamawa

Tsarin na'ura mai aiki da karfin ruwa (haɗin tashar ruwa, silinda na hydraulic, kayan aiki na musamman, da dai sauransu) yana haifar da karfi mai karfi don fahimtar sassan. Siffofinsa sune cewa ƙarfin kamawa yana da girma, tsarin ɗagawa abin dogaro ne, sarrafawa daidai ne, kuma aikin yana da hankali. Duk da haka, tsarin na'ura mai aiki da karfin ruwa yana da lahani Matsalar zubar da man fetur zai faru. Saboda tasirin yanayi da lokaci, roba yana rufewa a cikin injin ruwa bawuls da na'ura mai aiki da karfin ruwa Silinda za su tsufa da kuma qualitatively canza, wanda zai haifar da na'ura mai aiki da karfin ruwa yayyo da kuma matsa lamba asara. Kudin kulawa yana da girma.

Saboda ƙarfin damƙar hydraulic yana da girma sosai, lokacin amfani da wannan hanyar karɓi, dole ne ku yi la'akari da inganci da tsayayyen tsarin sassan da aka kama, kuma ku cika ƙididdige ƙarfin ɗaukar ma'aikacin na'ura mai ba da hanya tsakanin hanyoyin sadarwa don guje wa wuce gona da iri. Babban yana haifar da lalacewa da lalata sassa. A lokaci guda, a cikin zaɓin bawul ɗin solenoid da ƙirar ka'idodin kulawar hydraulic, dole ne a yi la'akari da amincin tsarin ɗaukar nauyi. Alal misali, yadda za a magance zubar da ruwa, ko akwai daidaitaccen Injin kulle kai don hana sassa daga faɗuwa, shin akwai wata hanya mai aminci a cikin yanayin manipulator, da dai sauransu?

2. Haɗawa da kamawa

Haɗuwa da tsarin pneumatic (aiki na iska, bawuloli na solenoid, cylinders, na musamman maras motsi, da sauransu) yana haifar da daidaitaccen ƙarfi don ɗaukar sassa. Siffofinsa sune tsari mai sauƙi, ƙananan ƙarfin fitarwa, saurin ƙulla amsawa, da kiyayewa Kudin yana da ƙasa, amma maƙarƙashiyar pneumatic shima yana da wasu lahani. Saboda matsawar iska, kwanciyar hankali na saurin aiki ba shi da kyau. A cikin aiwatar da matsawa iska, yana da sauƙi don samar da ƙura, ruwa da sauran mujallu, wanda ke haifar da lalacewar abubuwan pneumatic. Yawan lalacewa da maye gurbin ya yi yawa, kuma amincin yana raguwa sosai. Yin amfani da bututun iska yana da matukar rauni ga tasirin muhalli, wanda zai iya haifar da tsufa, fashewa da haifar da zubewar tushen iska. Kuma saboda ƙaramar ƙarfi, lokuttan aikace-aikacen sa Hakanan yana da wasu iyakoki.

Labarin namu ya fi raba hanyoyin danne huhu guda biyu, waɗanda kuma hanyoyin haɗin gwiwa biyu ne na gama-gari don matse huhu.

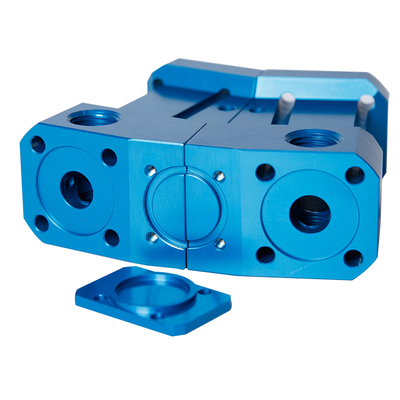

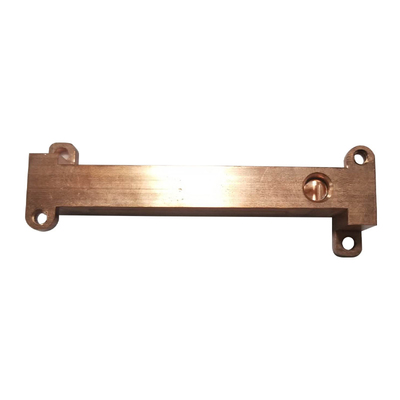

Ƙarfin ƙwanƙwasa da bugun bugun wannan yatsan huhu yana da ƙanƙanta, wanda ya dace da ɗaukar wasu ƙananan sassa. Ana amfani dashi sosai a cikin taro da yawa da sarrafa layukan atomatik. Lokacin zabar, dole ne ku kula da matsakaicin matsa lamba kuma zaɓin bugun jini dole ne ya cika buƙatun ƙirar ku. A lokaci guda, saboda ƙusoshin wannan ɓangaren sun yi tsayi sosai, muna buƙatar yin zane-zane masu dacewa bisa ga siffar da halaye na sassan da aka ƙulla yayin amfani, kuma dole ne mu yi la'akari da su sosai. Rigidity bukatun da sa juriya bukatun, saboda aiki na atomatik line ne babban adadin maimaita matakai, don haka ga zane na clamping jaws, mu bayar da shawarar cewa lamba sassa ya kamata a quenched ko alloyed, wanda zai iya ƙwarai inganta juriya na juriya. muƙamuƙi masu matsawa. Digiri na nika.

A lokaci guda kuma, zaɓaɓɓun skru ɗin da aka zaɓa ya kamata su yi ƙoƙarin zaɓar screws masu ƙarfi, kamar sukurori 12.9. Saboda kafaffen sukurori na wannan nau'in suna da ɗan ƙaramin ƙarfi, screws na ƙarfin gabaɗaya yana da sauƙin karya da zame hakora. A gaskiya ma, maganin waɗannan cikakkun bayanai Shi ne garanti mafi aminci don kwanciyar hankali na layin atomatik.

Domin amfani da injin tsotsa kofuna, dole ne mu yi la'akari sosai da ingancin sassan da za a kama da kuma saman gama, domin kawai in mun gwada da kyau surface gama zai iya samar da injin tsotsa smoothly da samar da abin dogara gripping da tsotsa karfi.

Dole ne kuma mu yi la'akari daban-daban Bayyanawa ga kaushi zai shafi lalata da kuma tsufa na vacuum chucks. Misali, yawanci muna amfani da vacuum chucks akan layukan sarrafawa ta atomatik. Yawancin masu sanyaya kayan aiki suna da wani sakamako mai lalacewa, musamman ga samfuran filastik, don haka yana da sauƙi don haifar da tsufa na chucks.

A wannan lokacin, muna buƙatar yin wasu buƙatu na musamman da tuntuɓar masu ba da ƙoƙon injin tsotsa akan kayan miya mai tsotsa. Lokacin da ya cancanta, zamu iya tambayar ɗayan ɓangaren don samar da samfurori masu dacewa don gwaji sannan kuma kammala siffar.

Bugu da kari, a kula da tsafta da tsaftar injin janareta, domin bayan an danne iska, ita ma za a danne kurar da ke cikin iska. Bayan haxawa da ruwa da hazo mai a cikin iskar da aka matse, za ta zama sludge, wanda zai toshe injin.

Sakamako na ƙarshe shine ƙarfin tsotsa na kofin tsotsa ya ragu sosai, kuma ba za a iya kama aikin ba akai-akai. A wannan yanayin, zamu iya maye gurbin injin janareta ko kuma murkushe ainihin injin injin don tsaftacewa.

3. Electromagnet kama

Ana kama sassan da tsarin lantarki. Aikace-aikacen wannan tsarin lantarki yana da wasu iyakoki. Misali, kawai zai iya fahimtar wasu takamaiman sassa waɗanda na'urar lantarki zata iya ɗauka. A yawancin lokuta, ƙila ba za a yi amfani da shi ba, misali, kuna son fahimta.

Don samfurin filastik, taurin kai irin wannan hanyar kamawa ba ta dace ba. Hanyar kama hanyar electromagnet yana da tsayayye kuma abin dogaro, ƙarfin talla yana da ƙarfi sosai, kuma tsarin yana da sauƙi kuma a sarari, amma kuma yana da wasu munanan illolin, misali, za a yi magnetized kuma a kama shi. Sassan, akwai wasu bukatu na tsari, akwai wasu ɓoyayyun haɗari na aminci lokacin da aka yanke wutar ba zato ba tsammani, kuma farashin kulawa da kofa yana da girma.

Akwai zaɓuɓɓuka guda biyu don wannan hanyar kamawa na lantarki:

- 1) Ƙarfafawa tare da magnetism. A karkashin yanayi na al'ada, irin wannan nau'in electromagnet ba shi da ƙarfi. Sai kawai lokacin da aka ƙarfafa shi, zai samar da magnetism mai dacewa, kuma magnetism zai haifar da karfin adsorption. Bayan an kashe wutar lantarki, maganadisu ya ɓace kuma yana jan hankali. Ƙarfin kuma ya ɓace. Tabbas, idan na'urar lantarki tana da girma, maganadisu ba zai ɓace nan take ba, kuma za a sami wani yanayi na sake dawowa. Sabili da haka, lokacin zabar irin wannan hanyar kamawa, dole ne ku yi la'akari da girman ragowar da kuma lokacin cikakken demagnetization. . Sannan ga na’urorin lantarki da yawa, lokacin kuzarin ba zai yi tsayi da yawa ba, domin tsawon lokacin kuzarin zai sa wutar lantarki ta yi zafi, kuma dumama da ake ci gaba da yi zai haifar da tsufa da lalacewar na’urar cikin sauƙi.

- 2) Magnet ne mai kuzari da demagnetized. A karkashin yanayi na al'ada, irin wannan maganadisu shine maganadisu. Lokacin da aka ƙarfafa shi, magnetism zai ɓace kuma ƙarfin tallan zai ɓace. Koyaya, wannan hanyar kamawa yawanci yana da tasiri daidai akan sassan da ke kewaye. Bukatar, saboda ana iya watsa ƙarfin maganadisu ta sararin samaniya, yana iya zama abin sha'awa ga wasu abubuwa yayin aiwatar da aiwatar da sassa, don haka ya kamata a ba da cikakkiyar kulawa yayin zayyana.

Shiga wannan labarin : Zaɓi Da Zane Na Hanyar Rarraba Manipulator

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan