Fasahar Jiyya ta Farfajiyar Alloy Aluminum

Fasahar Jiyya ta Farfajiyar Alloy Aluminum

|

Aluminum yana da fa'idodi da yawa kamar ƙarancin ƙarancin ƙarfi, ƙayyadaddun ƙarfi na musamman, juriya mai kyau na lalata, haɓakar wutar lantarki da haɓakar thermal, weldability, filastik mai kyau, sauƙin sarrafawa da haɓakawa, da kyawawan kaddarorin kayan ado na saman. Aluminum alloy an yi shi da aluminium mai tsafta ta hanyar ƙara wasu abubuwa masu haɗawa. Aluminum alloy ya fi aluminium mai tsabta. Aluminum yana da mafi kyawun kayan jiki da na inji. Saboda yanayin aiki na aluminum, zai iya samar da fim ɗin amorphous oxide a cikin iska ba tare da bata lokaci ba, yana sa ya sami mafi kyawun juriya a cikin yanayi, amma kauri na fim ɗin kusan 4nm ne kawai, kuma tsarin yana da sako-sako, bakin ciki da bakin ciki. Porous, ƙananan taurin, juriya mara kyau, da ƙananan ƙarfin inji, don haka ya zama dole don rufe murfin aluminum da hannu tare da fim don cimma manufar kariya. Yawancin lokaci ana iya samun shi ta hanyar maganin oxygenation, electroplating, da shafi na waje. |

1 Maganin Oxidation

Maganin oxidation shine yafi anodic oxidation, sinadarai oxidation, da micro-arc oxidation. Xu Lingyun et al. [1] yayi nazarin kaddarorin injina da juriyar lalata na A356 aluminum gami ta hanyar yin abubuwa daban-daban guda uku surface jiyyas: sinadaran oxidation, anodization da micro-arc oxidation. Ta hanyar SEM fasaha, sa gwajin da kuma lalata juriya gwajin, da surface ilimin halittar jiki, oxide Layer kauri, sa juriya da kuma lalata juriya na aluminum gami bayan uku surface jiyyaAn yi nazari da kwatanta s dalla-dalla. Sakamakon ya nuna cewa bayan daban-daban surface jiyyas, da aluminum gami surface iya samar da oxide fina-finai na daban-daban kauri, da surface taurin da sa juriya suna da muhimmanci inganta, da kuma lalata juriya na gami kuma inganta zuwa sãɓãwar launukansa digiri. Dangane da aikin gabaɗaya, iskar oxygen ɗin micro-arc ya fi anodic oxidation, kuma oxidation anodic ya fi oxidation na sinadarai.

1.1 Anodizing

Anodizing kuma ana kiransa oxidation electrolytic, wanda shine ainihin magani na oxidation na electrochemical. Yana amfani da aluminum da aluminum gami a matsayin anodes a cikin electrolytic cell, da kuma wani oxide film (yafi Al 2 O 3 Layer) da aka kafa a kan aluminum surface bayan da aka kunna. Fim ɗin oxide da aka samu ta hanyar anodic oxidation yana da juriya mai kyau na lalata, tsarin barga da sauƙin haɓakawa. Ita ce hanya mafi mahimmanci kuma mafi yawan gama gari don maganin aluminium da aluminium a cikin ƙasata ta zamani. Fim ɗin oxide na anodic yana da halaye masu yawa: shinge mai shinge na fim ɗin oxide yana da tauri mai ƙarfi, juriya mai kyau, juriya mai kyau, kayan haɓaka mai kyau, babban kwanciyar hankali na sinadarai, kuma ana iya amfani dashi azaman fim mai tushe don sutura; fim din oxide yana da nau'i-nau'i masu yawa kuma ana iya amfani dashi Ana amfani dashi a cikin rini da canza launi daban-daban don ƙara yawan kayan ado na saman aluminum; da thermal conductivity na fim din oxide yana da ƙasa sosai, kuma yana da kyakkyawan kariya na thermal da kariya mai kariya mai zafi. Duk da haka, halin yanzu anodic hadawan abu da iskar shaka na aluminum da aluminum gami yawanci amfani da chromate a matsayin oxidant, wanda ya haifar da babban muhalli gurbatawa.

A cikin bincike na yanzu game da anodizing na aluminum da aluminum gami, an kuma biya hankali ga yin amfani da halaye na wasu nau'ikan ions na ƙarfe don haɓaka kaddarorin aluminum da aluminum gami. Alal misali, Tian Lianpeng [2] ya yi amfani da fasahar dasa ion wajen yin allurar titanium a saman na'urar alloy ta aluminum, sa'an nan kuma ya ƙara yin anodization don samun wani Layer na fim na aluminum-titanium composite anodized film Layer, wanda ya sanya fuskar fim din ya zama mai lebur kuma bai dace ba. , da kuma inganta anodization na aluminum gami. Yawan fim din; Ƙaddamarwar titanium ion na iya inganta haɓakar juriya na aluminum gami da anodic oxide fim a cikin acid da alkaline NaCl mafita, amma ba ya shafar tsarin amorphous na aluminum gami da anodic oxide fim. Nickel ion implantation yana sa tsarin farfajiya da yanayin halittar fim ɗin anodic oxide na aluminium ya fi girma da ɗari. Nickel ɗin da aka yi masa allura yana wanzuwa a cikin nau'in nickel na ƙarfe da nickel oxide a cikin fim ɗin alloy anodic oxide na aluminum.

1.2 Chemical oxidation

Chemical oxidation yana nufin hanyar da aka shafa a cikin abin da mai tsabta na aluminum yana hulɗa tare da iskar oxygen a cikin maganin oxidizing ta hanyar aikin sinadarai a ƙarƙashin wasu yanayin zafi don samar da fim din oxide mai yawa. Akwai hanyoyi da yawa na iskar shaka sinadarai don aluminum da aluminum gami, bisa ga yanayin maganin

Ana iya raba shi zuwa alkaline da acidic. Dangane da yanayin fim ɗin, ana iya raba shi zuwa fim ɗin oxide, fim ɗin phosphate, fim ɗin chromate da fim ɗin chromic acid-phosphate. Fim ɗin oxide da aka samu ta hanyar sinadarai na oxidation na aluminum da aluminum gami sassa yana da kauri na kusan 0.5 ~ 4μm. Yana da ƙarancin lalacewa juriya da ƙananan juriya na lalata fiye da fim ɗin anodic oxide. Bai dace a yi amfani da shi kadai ba, amma yana da wasu juriya na lalata da kyawawan kaddarorin jiki. Ƙarfin shayarwa shine kyakkyawan ma'auni don zanen. Paint bayan sinadaran hadawan abu da iskar shaka na aluminum da aluminum gami iya ƙwarai inganta bonding karfi tsakanin substrate da shafi, da kuma inganta lalata juriya na aluminum [3].

1.3 Micro-arc oxidation Hanyar

Fasahar oxidation na micro-arc kuma ana kiranta da fasaha ta micro-plasma oxidation ko fasaha ta anode spark deposition, wanda wani nau'in girma ne a cikin wurin ta hanyar fitar da micro-plasma a saman karfe da gami. Oxidation

Sabuwar fasaha na yumbu membrane. Fim ɗin saman da aka kafa ta wannan fasaha yana da ƙarfin haɗin gwiwa tare da substrate, babban taurin, juriya mai juriya, juriya na lalata, juriya mai ƙarfi na thermal, ingantaccen rufin lantarki na fim ɗin, da babban ƙarfin rushewa. Ba wai kawai ba, fasahar tana ɗaukar hanyar dumama hanyar dumama micro plasma arc dumama tare da matsanancin ƙarfin kuzari, tsarin matrix bai shafi ba, kuma tsarin ba shi da wahala, kuma baya haifar da gurɓataccen muhalli. Yana da wani m sabon abu surface jiyya fasaha. Yana zama wurin bincike a fagen fasahar injiniyan kayan ƙasa ta ƙasa. Zhang Juguo et al.

Used sarrafa aluminium alloy LY12 a matsayin kayan gwajin, an yi amfani da MAO240/750 micro-arc oxidation kayan aiki, TT260 kauri ma'auni da AMARY-1000B scanning electron microscope don nazarin sakamakon wutar lantarki, halin yanzu yawa da hadawan abu da iskar shaka lokaci a kan yumbu Layer. Tasirin aiki. Ta hanyar jerin gwaje-gwajen gwaje-gwaje na ƙirar ƙirar ƙirar ƙirar aluminum gami da Na 2 SiO 3 electrolyte, ka'idar girma na fim ɗin yumbu oxide yayin tsarin iskar oxygen na micro-arc da tasirin nau'ikan nau'ikan lantarki daban-daban da maida hankali kan ingancin yumbu oxide. ana nazarin fim. A micro-arc hadawan abu da iskar shaka na aluminum gami surface ne mai matukar rikitarwa tsari, ciki har da electrochemical samuwar na farko oxide fim, da kuma m rushewar yumbu film, wanda ya hada da jiki sakamakon thermochemistry, electrochemistry, haske, wutar lantarki, da zafi. .

Wani tsari yana shafar kayan aikin da kanta, sigogin samar da wutar lantarki, da sigogin lantarki, kuma yana da wahala a saka idanu akan layi, wanda ke kawo matsaloli ga binciken ka'idar. Saboda haka, ya zuwa yanzu, babu wani samfurin ka'idar da zai iya bayyana abubuwan gwaji daban-daban masu gamsarwa, kuma bincike kan tsarin sa yana buƙatar ƙarin bincike da haɓakawa.

2 Electroplating da sinadarai plating

Electroplating shi ne sanya wani Layer na sauran karfe rufi a kan saman aluminum da aluminum gami ta hanyar sinadaran ko electrochemical hanyoyin, wanda zai iya canza jiki ko sinadaran Properties na aluminum gami surface. saman

Gudanarwa; jan karfe, nickel ko tin plating na iya inganta weldability na aluminum gami; da gwangwani mai zafi-tsoma ko aluminum-tin alloy na iya inganta lubricant na aluminum gami; gabaɗaya inganta taurin saman da kuma sa juriya na gami da aluminum tare da plating chromium ko plating nickel; Chrome ko nickel plating kuma na iya inganta kayan adonsa. Aluminum za a iya electrolyzed a cikin electrolyte don samar da wani shafi, amma da shafi yana da sauki bawo. Don magance wannan matsala, ana iya ajiye aluminum da kuma rufe shi a cikin wani ruwa mai ruwa mai dauke da sinadarin zinc. Tushen nutsewar zinc shine ya haɗu da aluminium da matrix ɗin alloy ɗin sa da kuma abubuwan da suka biyo baya. Muhimmiyar gada, Feng Shaobin et al. [7] yayi nazarin aikace-aikace da kuma tsarin da ke cikin tudun nutsewa na zinc akan ma'aunin aluminum, kuma ya gabatar da sabuwar fasaha da aikace-aikacen tsarin nutsarwar zinc. Electroplating bayan nutsewa a cikin zinc kuma yana iya samar da fim na bakin ciki na bakin ciki a saman aluminum sannan kuma a sanya wutar lantarki.

Electroless plating yana nufin fasahar samar da fina-finai inda ake ajiye murfin ƙarfe a saman ƙarfe ta hanyar sinadarai na autocatalytic a cikin wani bayani da ke kasancewa tare da gishirin ƙarfe da wakili mai ragewa. Daga cikin su, abin da aka fi amfani da shi shine Ni-P alloy plating mara amfani. Idan aka kwatanta da tsarin lantarki, plating mara amfani shine a

Tsarin gurɓataccen gurɓataccen yanayi, Ni-P gami da aka samu shine kyakkyawan madadin chromium plating. Duk da haka, akwai kayan aiki da yawa na tsari don plating mara amfani, yawan amfani da kayan yana da girma, lokacin aiki yana da tsawo, hanyoyin aiki suna da wahala, kuma ingancin sassan plating yana da wuyar garanti. Misali, Feng Liming et al. [8] yayi nazarin ƙayyadaddun tsari don ƙarancin nickel-phosphorus alloy plating wanda kawai ya haɗa da matakan pretreatment kamar lalata, nutsewar zinc, da wanke ruwa dangane da abun da ke ciki na 6063 aluminum gami. Sakamakon gwaji ya nuna cewa tsarin yana da sauƙi, ƙananan nickel marar amfani da electroless yana da babban mai sheki, ƙarfin haɗin gwiwa mai karfi, launi mai laushi, mai laushi mai laushi, abun ciki na phosphorus tsakanin 10% da 12%, da kuma taurin jihar plating zai iya kaiwa fiye da 500HV. wanda ya fi na anode yawa. Oxide Layer [8]. Baya ga na'urar Ni-P alloy plating maras amfani, akwai sauran allunan, irin su Ni-Co-P gami da Yang Erbing [9] ya yi nazari. Fim ɗin yana da babban ƙarfin ƙarfi, ƙananan remanence da kyakkyawar juyawa na lantarki. Siffofin, ana iya amfani da su a cikin manyan faifai masu yawa da sauran filayen, tare da plating maras amfani

Hanyar Ni-Co-P na iya samun kauri iri ɗaya da fim ɗin magnetic alloy akan kowane nau'in sifa mai rikitarwa, kuma yana da fa'idodin tattalin arziƙi, ƙarancin kuzari da aiki mai dacewa.

3 Shafi saman

3.1 Laser cladding

A cikin 'yan shekarun nan, yin amfani da Laser katako mai ƙarfi mai ƙarfi don jiyya na cladding Laser akan saman alloy na aluminium na iya inganta haɓakar tauri da ci gaba da juriya na aluminum da aluminum gami. Misali, ana amfani da Laser 5kW CO 2 don rufe murfin plasma na Ni-WC akan saman alloy ZA111. Layer Fusion Laser da aka samu yana da tauri mai girma, kuma lubrication, lalacewa da juriya na abrasion shine sau 1.75 na abin da aka fesa ba tare da maganin laser ba kuma sau 2.83 na Al-Si gami matrix. Zhao Yong [11] ya yi amfani da laser CO 2 a cikin aluminum da aluminum gami substrates

An shafe shi da Y da Y-Al foda shafi, da foda ne mai rufi a kan surface na substrate ta hanyar da aka saita foda shafi hanya, da Laser wanka yana da kariya ta argon, da wani adadin CaF 2, LiF da MgF 2 ne. ƙara azaman wakili mai ƙira Ƙarƙashin ƙayyadaddun sigogin tsari na cladding Laser, ana iya samun uniform da ci gaba da sutura mai yawa tare da ƙirar ƙarfe. Lu Weixin [12] yayi amfani da CO 2 Laser don shirya Al-Si foda shafi, Al-Si + SiC foda shafi da Al-Si + Al 2 O 3 foda shafi a kan aluminum gami substrate ta Laser cladding hanya. , Al'ada foda shafi. Zhang Song et al. [13] yayi amfani da 2 kW ci gaba Nd: YAG Laser a AA6 0 6 1 aluminum

Fuskar da aka yi amfani da ita shine Laser cladding tare da SiC yumbu foda, da kuma surface karfe matrix composite (MMC) modified Layer za a iya shirya a saman da aluminum gami ta Laser narkewa magani.

3.2 Rubutun da aka haɗa

Rubutun da aka haɗa da aluminum gami da kai mai lubricating tare da kyawawan abubuwan haɓakawa da haɓakar lalacewa yana da kyakkyawan fata na aikace-aikacen injiniya, musamman a fagen fasaha mai ƙima. Sabili da haka, membrane na alumina mai laushi tare da tsarin matrix na pore shima ya sami ƙarin kulawa daga mutane. Hankali, fasaha mai hade da aluminum gami da fasaha ya zama ɗaya daga cikin wuraren bincike na yanzu. Qu Zhijian [14] yayi nazarin aluminium da 6063 aluminium gami da fasaha mai ruɓi mai haɗaka da kai. Babban tsari shine aiwatar da anodization mai ƙarfi akan aluminum da 6063 aluminum gami, sannan amfani da hanyar tsomawa mai zafi don gabatar da ƙwayoyin PTFE a cikin pores na fim ɗin oxide. Kuma saman, bayan tsabtace madaidaicin zafin zafi, an samar da suturar hade. Li Zhenfang [15] ya yi bincike kan wani sabon tsari da ya hada fenti na guduro da tsarin sarrafa wutar lantarki a saman ƙafafun alloy na aluminum da ake amfani da su a cikin motoci. Lokacin gwajin CASS shine sa'o'i 66, ƙimar blistering shine ≤3%, ƙimar yuwuwar jan ƙarfe shine ≤3%, an rage ma'auni mai ƙarfi ta 10 ~ 20g, kuma fentin resin da murfin ƙarfe suna da kyan gani.

4 Sauran hanyoyin

4.1 Hanyar shigar da ion

Hanyar dasa ion tana amfani da katakon ion mai ƙarfi don jefa bama-bamai a cikin yanayi mara kyau. Kusan kowane ion dasawa za a iya cimma. Ions da aka dasa suna baci kuma an bar su a cikin matsayi na maye ko matsayi na rata na ingantaccen bayani don samar da shimfidar shimfidar wuri mara daidaituwa. Aluminum gami

An inganta taurin saman, juriya na sawa da juriya na lalata. Magnetron sputtering tsantsa titanium wanda PB11 nitrogen / carbon implantation zai iya ƙwarai inganta microhardness na modified surface. Magnetron sputtering hade da nitrogen allura iya ƙara taurin da substrate daga 180HV zuwa 281.4HV. Magnetron sputtering hade da carbon allura zai iya ƙara zuwa 342HV [16]. Magnetron sputtering tsantsa titanium wanda PB11 nitrogen / carbon implantation zai iya ƙwarai inganta microhardness na modified surface. Liao Jiaxuan et al. [17] ya yi aikin haɗakar da titanium, nitrogen, da carbon bisa tushen ion da aka yi amfani da shi na plasma na LY12 aluminum gami, kuma ya sami tasirin gyare-gyare. Zhang Shengtao da Huang Zongqing na Jami'ar Chongqing [18] sun gudanar da dasa ion titanium akan gami da aluminium. Sakamakon ya nuna cewa gyare-gyaren ion titanium a kan saman aluminum gami shine hanya mai mahimmanci don inganta juriya ga lalata ion chloride, kuma yana iya inganta ƙarfin aluminum gami don tsayayya da lalata ion chloride. Fadada yuwuwar yuwuwar wucewar gami na aluminium a cikin NaCl da sauran mafita, da rage yawa da girman ramukan lalata da ions chloride suka lalata.

4.2 Rare duniya canza shafi

Rufin jujjuyawar ƙasa da ba kasafai ba na iya inganta juriya na almuran alloys, kuma tsarin shine yawancin nutsewar sinadarai. Rare ƙasa yana da amfani ga aluminum gami anodic hadawan abu da iskar shaka. Yana haɓaka ikon aluminum gami don karɓar polarization kuma a lokaci guda yana haɓaka juriya na lalata fim ɗin oxide. Don haka, ana amfani da ƙasa mai ƙarancin ƙarfi a ciki

Aluminum alloy surface jiyya yana da kyau ci gaban al'amurra [19]. Shi Tie et al. [20] yayi nazarin tsarin samar da fim ɗin gishirin cerium akan saman tsatsa-hujja aluminium LF21 ta hanyar shigar da wutar lantarki. An yi amfani da gwaji na orthogonal don nazarin tasirin abubuwan da ke da alaƙa a kan tsarin samar da fim kuma an sami mafi kyawun ma'auni na fasaha. Sakamakon ya nuna cewa an toshe tsarin lalatawar anodic na tsatsa-hujja aluminium bayan da aka yi la’akari da abubuwan da aka yi amfani da su na electrolytic na fim ɗin juyawa na duniya, juriya ta lalata ta inganta sosai, kuma an inganta haɓakar hydrophilicity. Zhu Liping et al. [21] An yi amfani da sikanin microscopy na lantarki (SEM), makamashi spectroscopy (EMS) da hanyoyin gwajin gwajin gishiri don nazarin tsari da tsari, abun da ke ciki da ƙaƙƙarfan alloy na aluminum gami da ƙarancin yumɓun yumɓun yumɓun gishiri akan juriyar lalatawar sa. Tasiri. Sakamakon binciken ya nuna cewa nau'in cerium na duniya da ba kasafai ba a cikin fim ɗin yana hana haɓakar lalatawar al'ada kuma yana haɓaka juriyar lalatarsa sosai.

Juriya na lalata yana taka muhimmiyar rawa. A zamanin yau, akwai hanyoyi daban-daban na jiyya na aluminum da aluminum, kuma aikin su yana karuwa da karfi, wanda zai iya biyan bukatun aluminum da aluminum gami a rayuwa, magani, aikin injiniya, sararin samaniya, kayan aiki, kayan lantarki, kayan abinci da kayan aiki. haske masana'antu, da dai sauransu Bukatar. A nan gaba, da surface jiyya na aluminum da aluminum gami zai zama mai sauki a cikin tsari kwarara, barga a inganci, babban-sikelin, makamashi-ceton, da kuma muhalli abokantaka.

Ci gaban shugabanci. Yana da toshe copolymer na ester-amide musayar amsa tare da babban juyi. Korshak et al. [11] ya ruwaito cewa lokacin da aka yi amfani da 1% PbO 2 ko 2% PbO 2 a matsayin mai haɓakawa kuma mai zafi a 260 digiri na 3-8 hours, amsawa tsakanin polyester da polyamide kuma zai faru. Hanyoyin musayar ester-amide yana da wani tasiri akan daidaitawar tsarin gauraya. Xie Xiaolin, Li Ruixia, da dai sauransu [12] ta amfani da bayani

Hanyar, sauƙi na inji mai sauƙi (hanyar narkewa 1) da kuma kasancewar ester-amide musayar amsawar hanyar haɗakarwa (hanyar narkewa) don haɗuwa da PET da PA66, nazarin DSC na tsari, da kuma dacewa da tsarin haɗakarwa na PET/PA66 An tattauna jima'i zuwa wani matsayi. Sakamakon ya nuna cewa tsarin haɗakarwa na PET/PA66 tsarin tsarin thermodynamically ne wanda ba zai dace ba, kuma dacewa da narke gauraya ya fi na narke cakuda, da kuma toshe copolymer da PET/PA66 saje ya dace da biyu The lokaci karfinsu. an inganta; tare da haɓakar abun ciki na PA66, wurin narkewa na haɗuwa ya ragu. PET/PA66 toshe copolymer da aka kirkira ta hanyar amsawa yana ƙara tasirin nucleation na PA66 akan lokacin crystallization na PET, wanda ya haifar da narkewa. Zhu Hong et al. [1] sunyi amfani da p-toluenesulfonic acid (TsOH) da titanate coupling agents a matsayin masu taimakawa ga ester-amide musayar amsa tsakanin Nylon-13 da PET don cimma daidaituwa a cikin-wuri na Nylon-6 / PET blends. Manufar binciken duban microscope na lantarki yana nuna cewa gauran Nylon-6/PET shine tsarin rabuwar lokaci na crystalline tare da rashin daidaituwa. Ƙara p-toluenesulfonic acid da titanate hada guda biyu wakili a matsayin mai kara kuzari don inganta in-wuri toshe samuwar Copolymer yana ƙara haɗin haɗin kai tsakanin sassan biyu, yana sa lokacin da aka tarwatsa ya zama mai ladabi da rarraba iri ɗaya, kuma yana taimakawa wajen ƙara aikin yaduwa na gauraya. . Dukansu suna taimakawa wajen haɓaka daidaituwar haɗakarwa da haɓaka mannewar tsaka-tsaki na sassan biyu.

Hasashen 2

A cikin 'yan shekarun nan, masu bincike na gida sun yi aikin bincike da yawa a kan haɗin gwiwar polyamide / polyester kuma sun sami sakamako masu amfani da yawa, suna kafa tushe mai kyau don bincike na gaba a wannan yanki. A halin yanzu, abin da ya kamata a kula da shi shine haɓaka haɓaka haɓakar haɓakar kayan haɗin polyamide / polyester da kuma amfani da ƙarshen ƙarshe zuwa ainihin aikin samarwa. Ta hanyar gyaggyarawa biyun, ana samun sabon abu wanda ke kula da fa'idodin sassan biyu. Yana da kyawawan kaddarorin inji, juriya na ruwa ya fi polyamide, kuma tasirin tasirin ya fi polyester. Ana amfani dashi sosai a cikin kayan lantarki, lantarki da masana'antar kera motoci. aikace-aikace.

Shiga wannan labarin : Fasahar Jiyya ta Farfajiyar Alloy Aluminum

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

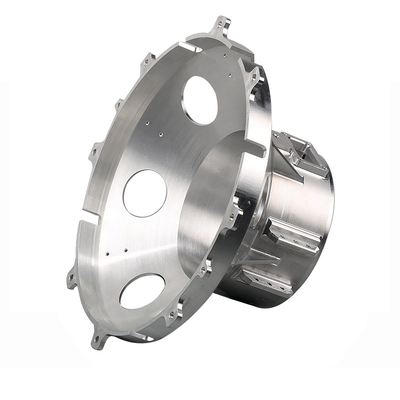

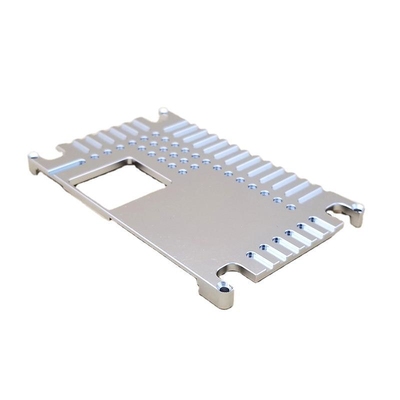

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan