Cikakken Ƙwarewar Ƙwarewar Hakowa da Ayyukan Cnc Machining!

01 Nasihu don amfani da sanyaya

Daidaitaccen amfani da na'ura mai sanyaya yana da mahimmanci don samun aikin hakowa mai kyau, kai tsaye zai shafi ƙaurawar guntu, rayuwar kayan aiki da ingancin ramin da aka yi amfani da shi a lokacin mashin ɗin.

(1) Yadda ake amfani da coolant

1) Tsarin sanyaya na ciki

Zane mai sanyaya na ciki koyaushe shine zaɓi na farko don gujewa toshe guntu, musamman lokacin sarrafa kayan guntu mai tsayi da hako rami mai zurfi (fiye da sau 3 diamita na rami). Don ƙwanƙwasa a kwance, lokacin da na'urar sanyaya ke fita daga cikin rawar sojan, bai kamata a sami ƙaramin ruwan yankan sama da tsayin akalla 30 cm ba.

2) Tsarin sanyaya na waje

Ana iya amfani da amfani da na'ura mai sanyaya waje lokacin da guntu samuwar yana da kyau kuma zurfin rami ba shi da zurfi. Domin inganta ƙaurawar guntu, yakamata a sami aƙalla bututun mai sanyaya guda ɗaya (ko nozzles guda biyu idan aikace-aikacen da ba mai jujjuya ba ne) kusa da axis ɗin kayan aiki.

3) Busassun dabarun hakowa ba tare da amfani da sanyaya ba

Ba a ba da shawarar busasshen hakowa gabaɗaya.

- a) Ana iya amfani da shi a aikace-aikace tare da gajeren kayan guntu da zurfin rami har zuwa sau 3 diamita

- b) Ya dace da kayan aikin injin kwance

- c) Ana bada shawara don rage saurin yankewa

- d) Rayuwar kayan aiki za ta ragu

Ana ba da shawarar kada a yi amfani da busasshen hakowa don:

- a) Bakin karfe abu (ISO M da S)

- b) Canjawar bit drill bit

4) Babban matsa lamba sanyaya (HPC) (~ 70 mashaya)

Fa'idodin yin amfani da sanyaya mai ƙarfi sune:

- a) Saboda ingantaccen tasirin sanyaya, rayuwar kayan aiki ya fi tsayi

- b) Haɓaka tasirin cire guntu a cikin mashin ɗin dogon kayan guntu kamar bakin karfe, kuma yana iya tsawaita rayuwar kayan aiki.

- c) Mafi kyawun aikin cire guntu, don haka aminci mafi girma

- d) Samar da isasshen kwarara bisa ga matsa lamba da aka ba da kuma girman rami don kula da samar da mai sanyaya

(2) Amfani da basirar sanyaya

Tabbatar amfani da man yankan mai narkewa (emulsion) mai ɗauke da EP (matsananciyar matsa lamba) ƙari. Domin tabbatar da mafi kyawun rayuwar kayan aiki, abun cikin mai a cikin cakuda mai-ruwa ya kamata ya kasance tsakanin 5-12% (tsakanin 10-15% lokacin sarrafa bakin karfe da kayan superalloy). Lokacin ƙara abun cikin mai na ruwan yankan, tabbatar da duba tare da mai raba mai don tabbatar da cewa abun da aka ba da shawarar mai bai wuce ba.

Lokacin da yanayi ya ba da izini, sanyaya na ciki koyaushe shine zaɓi na farko idan aka kwatanta da mai sanyaya waje.

Mai tsabta mai tsabta zai iya inganta tasirin lubrication kuma ya kawo fa'idodi lokacin hako aikace-aikacen bakin karfe. Tabbatar amfani da shi tare da abubuwan EP. Dukansu ƙaƙƙarfan ƙwanƙwasa ƙwanƙwasa na carbide da ƙwanƙwasa mai ƙididdigewa na iya amfani da mai mai tsabta kuma suna iya samun sakamako mai kyau.

Matsakaicin iskar, ruwan yankan hazo ko MQL (ƙananan lubrication) na iya zama zaɓi mai nasara a ƙarƙashin ingantattun yanayi, musamman lokacin yin wasu ƙarfe na simintin ƙarfe da gami na aluminum. Kamar yadda yawan zafin jiki zai iya haifar da mummunar tasiri akan rayuwar kayan aiki, ana bada shawara don rage saurin yankewa.

02 Ƙwarewar sarrafa guntu

Ƙirƙirar guntu da cire guntu su ne manyan batutuwa a cikin hakowa, ya danganta da kayan aikin aikin, zaɓin juzu'i / juzu'i na ruwa, matsa lamba / ƙarfi, da yanke sigogi.

Katange kwakwalwan kwamfuta zai sa rawar motsa jiki ta motsa cikin radially, wanda zai shafi ingancin rami, rawar soja da aminci, ko haifar da rawar soja / ruwa ta karye.

Lokacin da guntuwar za a iya fitar da su lafiyayye daga ɗigon rawar soja, ƙirar guntu abin karɓa ne. Hanya mafi kyau don gane shi ita ce saurare yayin aikin hakowa. Ci gaba da sauti yana nuna kyakkyawan ƙaurawar guntu, kuma sautin tsaka-tsakin yana nuna guntuwar guntu. Bincika ƙarfin ciyarwa ko duban wuta. Idan akwai rashin daidaituwa, dalilin zai iya toshe kwakwalwan kwamfuta. Duba kwakwalwan kwamfuta. Idan kwakwalwan kwamfuta suna da tsayi kuma suna lanƙwasa, amma ba a murƙushe su ba, yana nufin cewa guntuwar sun toshe. Duba rami. Bayan toshewar ya faru, za a ga wani wuri mara kyau.

Nasihu don guje wa guntu:

- 1) Tabbatar cewa an yi amfani da daidaitattun sigogin yanke da kuma rawar gani/kayan kayan aiki

- 2) Bincika siffar guntu-daidaita ƙimar ciyarwa da sauri

- 3) Duba yankan ruwa kwarara da kuma matsa lamba

- 4) Duba yankan gefen. Lokacin da gabaɗayan chipbreaker ba ya aiki, ɓacin rai/guntu na iya haifar da dogon guntu

- 5) Bincika ko an canza machinability saboda sabon tsari na workpieces-daidaita sigogin yanke.

(1) Chips daga ƙwanƙwasa ƙwanƙwasa mai ƙididdigewa

Chips ɗin da aka ɗora ta hanyar tsakiyar ruwa yana da sauƙin ganewa. Chips ɗin da aka kafa ta abubuwan da ake sakawa na gefe suna kama da juyawa.

(2) Chips daga tsattsauran raƙuman motsi na carbide

Ana iya kafa guntu daga tsakiyar yankan gefen zuwa gefen. Ya kamata a lura da cewa kwakwalwan kwamfuta na farko da aka haifar yayin da ake hakowa a cikin kayan aikin a farkon koyaushe suna da tsayi sosai, amma wannan baya haifar da matsala.

(3) Chips daga maɓalli mai musanya

03 Sarrafa abinci da saurin yankewa

(1) Tasirin yanke saurin Vc (m/min)

Baya ga taurin kayan, yanke saurin kuma shine babban abin da ke shafar rayuwar kayan aiki da amfani da wutar lantarki.

- 1) Yanke gudun shine abu mafi mahimmanci wajen ƙayyade rayuwar kayan aiki

- 2) Yanke gudun zai shafi ikon PC (kW) da karfin karfin Mc (Nm)

- 3) Gudun yankan mafi girma zai haifar da zafin jiki mafi girma da kuma ƙara yawan lalacewa, musamman a tip kayan aiki na gefe

- 4) Lokacin yin machining wasu taushi dogon guntu kayan (watau low carbon karfe), mafi girma yankan gudun ne m ga guntu samuwar.

Gudun yanke ya yi yawa:

- a) Gefen gefe yana sawa da sauri

- b) Nakasar filastik

- c) Rashin ingancin rami da ƙarancin diamita

Gudun yanke ya yi ƙasa da ƙasa:

- a) Samar da ginanniyar ƙari

- b) Rashin cire guntu mara kyau

- c) Tsawon lokacin yankewa

(2) Tasirin ciyarwar fn (mm/r)

- 1) Tasiri samuwar guntu, ingancin saman da ingancin rami

- 2) Tasirin Pc (kW) da karfin juyi Mc (Nm)

- 3) Babban ciyarwa zai shafi ƙarfin ciyarwa Ff (N), wanda ya kamata a yi la'akari da shi lokacin da yanayin aiki ba shi da tabbas

- 4) Shafi damuwa na inji da damuwa na thermal

Yawan ciyarwa:

- a) Hard guntu breaking

- b) gajeriyar lokacin yankewa

- c) Rashin kayan aiki ƙanƙanta ne amma haɗarin guntuwar hazo yana ƙaruwa

- d) An rage ingancin rami

Ƙananan ƙimar ciyarwa:

- a) guntu masu tsayi da sirara

- b) Inganta inganci

- c) Gaggauta lalacewa kayan aiki

- d) Tsawon lokacin yankewa

-

e) Lokacin hako sassa na bakin ciki tare da rashin ƙarfi mara kyau, ƙimar ciyarwar yakamata a kiyaye ƙasa kaɗan

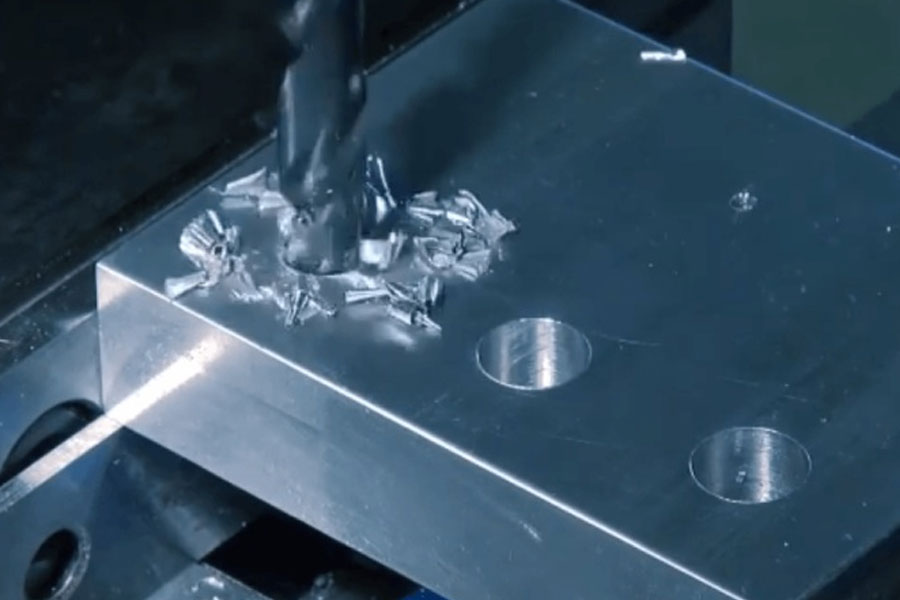

hoto

04 Nasiha don samun ramuka masu inganci

(1) Cire guntu

Tabbatar cewa aikin cire guntu ya cika buƙatun. Chip clogging yana shafar ingancin rami, dogaro da rayuwar kayan aiki. Matsakaicin rawar jiki/saka lissafin lissafi da yankan sigogi suna da mahimmanci.

(2) Kwanciyar hankali, danne kayan aiki

Yi amfani da mafi ƙarancin yuwuwar rawar soja. Yi amfani da ingantaccen mariƙin kayan aiki tare da mafi ƙarancin gudu. Tabbatar cewa sandal ɗin injin yana cikin yanayi mai kyau kuma yana daidaita daidai. Tabbatar cewa sassan sun daidaita kuma sun tsaya. Aiwatar da daidaitaccen adadin ciyarwa don filaye marasa daidaituwa, filaye masu karkata da ramukan giciye.

(3) Rayuwar kayan aiki

Bincika lalacewa na ruwa kuma saita tsarin sarrafa rayuwar kayan aiki. Hanyar da ta fi dacewa ita ce a yi amfani da na'urar lura da ƙarfin ciyarwa don lura da hakowa.

(4) Kulawa

Sauya dunƙule matsawar ruwa akai-akai. Tsaftace mariƙin wuka kafin musanya ruwan, tabbatar da yin amfani da maƙarƙashiya mai ƙarfi. Kar a wuce matsakaicin adadin lalacewa kafin sake niƙa da ƙaƙƙarfan rawar sojan carbide.

05Kwarewar hakowa don kayan daban-daban

(1) Dabarun hakowa don ƙaramin ƙarfe

Don ƙananan ƙarfe na carbon waɗanda galibi ana amfani da su don sassa na walda, samuwar guntu na iya zama matsala. Ƙarƙashin taurin, abun cikin carbon, da sulfur na ƙarfe, mafi tsayin kwakwalwan kwamfuta da aka samar.

- 1) Idan matsalar tana da alaƙa da ƙirƙira guntu, ƙara saurin yankan vc kuma rage fn abinci (da fatan za a lura cewa lokacin sarrafa ƙarfe na yau da kullun, yakamata a ƙara ciyarwar).

- 2) Yi amfani da babban matsin lamba da wadatar sanyaya na ciki.

(2) Dabarun hakowa don austenitic da duplex bakin karfe

Austenitic, duplex da super duplex kayan na iya haifar da matsaloli masu alaƙa da samuwar guntu da ƙaurawar guntu.

- 1) Madaidaicin lissafi yana da matukar mahimmanci, saboda yana iya sanya kwakwalwan kwamfuta su zama daidai kuma yana taimaka musu a cire su. Gabaɗaya magana, yana da kyau a yi amfani da yankan yankan kaifi. Idan matsalar tana da alaƙa da ƙirƙira guntu, ƙara fn fn zai sa guntu ta yi yuwuwar karyewa.

- 2) Tsarin sanyaya na ciki, babban matsa lamba.

(3) CGI (m graphite cast iron) gwanin hakowa

CGI yawanci baya buƙatar kulawa ta musamman. Yana samar da manyan guntu fiye da baƙin ƙarfe simintin toka, amma guntuwar suna da sauƙin karye. Ƙarfin yankewa ya fi girma kuma saboda haka yana rinjayar rayuwar kayan aiki. Bukatar amfani da kayan da ke jure lalacewa. Za a sami irin kayan aiki na kayan aiki na yau da kullun kamar duk simintin ƙarfe.

- 1) Idan matsalar tana da alaƙa da ƙirar guntu, ƙara saurin yankan Vc kuma rage fn.

- 2) Tsarin sanyaya na ciki.

(4) Aluminum gami da hakowa basira

Samuwar Burr da kwashe guntu na iya zama matsala. Hakanan yana iya haifar da gajeriyar rayuwar kayan aiki saboda tsayawa.

- 1) Don tabbatar da mafi kyawun samuwar guntu, yi amfani da ƙarancin abinci da babban saurin yankewa.

- 2) Don guje wa ɗan gajeren rayuwar kayan aiki, ana iya buƙatar ɗaukar sutura daban-daban don rage mannewa. Wadannan suturar na iya haɗawa da lu'u-lu'u lu'u-lu'u, ko babu abin rufewa kwata-kwata (dangane da ma'auni).

- 3) Yi amfani da emulsion mai ƙarfi ko hazo mai sanyaya.

(5) Ƙwarewar hakowa don kayan aikin titanium da kayan zafi mai zafi

Ƙarfafa aikin aikin rami yana rinjayar matakai masu zuwa. Yana da wahala a sami kyakkyawan aikin cire guntu.

- 1) Lokacin zabar geometry don machining titanium gami, yana da kyau a sami kaifi yankan. Lokacin da ake yin alluran tushen nickel, ƙaƙƙarfan lissafi yana da mahimmanci. Idan akwai matsalar taurin aiki, gwada ƙara yawan ciyarwar.

- 2) Babban mai sanyaya matsa lamba har zuwa mashaya 70 yana inganta aikin.

(5) Ƙwarewar haƙon karfe

Sami rayuwar kayan aiki karbuwa.

- 1) Rage saurin yanke don rage zafi. Daidaita adadin ciyarwa don samun karɓuwa da sauƙin fitar da kwakwalwan kwamfuta.

- 2) High-taro gauraye emulsion.

Shiga wannan labarin : Cikakken Ƙwarewar Ƙwarewar Hakowa da Ayyukan Cnc Machining!

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

3, 4 da 5-daidaici axis Cibiyar CNC ayyuka na kayan aikin aluminum, beryllium, carbon carbon, magnesium, kayan aikin titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite da itace. Mai iya sarrafa sassa har zuwa 98 in. Juyawa dia. da +/- 0.001 a. haƙuri madaidaiciya. Ayyuka sun haɗa da niƙa, juyawa, hakowa, m, zare, taɓi, ƙirƙira, dunƙulewa, murƙushewa, ƙididdigewa, sakewa da yankan laser. Sabis na sakandare kamar taro, nika marar tsakiya, maganin zafi, plating da walda. Samfurin samfuri da ƙarami zuwa ƙarar girma da aka bayar tare da matsakaicin raka'a 50,000. Ya dace da ikon ruwa, pneumatics, hydraulics da bawul aikace -aikace. Yana aiki da sararin samaniya, jirgin sama, soja, likitanci da masana'antun tsaro.PPJ zai yi dabarun yin aiki tare da ku don samar da mafi kyawun sabis masu tsada don taimaka muku isa ga burin ku, Barka da zuwa Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

3, 4 da 5-daidaici axis Cibiyar CNC ayyuka na kayan aikin aluminum, beryllium, carbon carbon, magnesium, kayan aikin titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite da itace. Mai iya sarrafa sassa har zuwa 98 in. Juyawa dia. da +/- 0.001 a. haƙuri madaidaiciya. Ayyuka sun haɗa da niƙa, juyawa, hakowa, m, zare, taɓi, ƙirƙira, dunƙulewa, murƙushewa, ƙididdigewa, sakewa da yankan laser. Sabis na sakandare kamar taro, nika marar tsakiya, maganin zafi, plating da walda. Samfurin samfuri da ƙarami zuwa ƙarar girma da aka bayar tare da matsakaicin raka'a 50,000. Ya dace da ikon ruwa, pneumatics, hydraulics da bawul aikace -aikace. Yana aiki da sararin samaniya, jirgin sama, soja, likitanci da masana'antun tsaro.PPJ zai yi dabarun yin aiki tare da ku don samar da mafi kyawun sabis masu tsada don taimaka muku isa ga burin ku, Barka da zuwa Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan