Yankan Laser na Femtosecond: Kayan sa da Aikace-aikace

Laser Ultrafast sun haɗa da picosecond da laser na femtosecond. Laser na Picosecond shine haɓaka fasahar fasahar nanosecond lasers, kuma picosecond lasers suna amfani da fasahar kulle yanayin, yayin da nanosecond lasers suna amfani da fasahar Q-switched. Fasahar Femtosecond tana amfani da hanyar fasaha mabambanta. Hasken da ke fitowa daga tushen iri yana faɗaɗa ta wurin shimfiɗar bugun bugun jini, ƙara ƙarfin ƙarfin CPA, kuma a ƙarshe ya matsa ta bugun bugun jini don cire hasken. Fasaha ya fi wahala.

Idan ya zo ga Laser na biyu na femtosecond, abu na farko da zai zo a hankali yana iya zama amfani da aka saba amfani da su kamar gyaran fuska na femtosecond myopia da cire freckle na femtosecond da ake amfani da su a fannin gyaran fuska na likitanci. Laser na Femtosecond kuma an raba su zuwa tsayin raƙuman ruwa daban-daban kamar infrared, koren haske, da ultraviolet. Daga cikin su, wuraren aikace-aikacen hasken infrared suna da fa'idodi na musamman: Za a iya shayar da Laser na infrared ta hanyar kayan ko kwayoyin halitta kuma ba su da kusan yankuna da ke fama da zafi a cikin Yankan Laser a masana'antu kamar kayan lantarki, photonics ko likita. A halin yanzu, ana iya amfani da shi a fannoni da yawa kamar daidaiton kayan yankan laser, tiyata, mabukaci, sadarwar lantarki, spectroscopy, sararin samaniya, aikace-aikacen tsaro da kimiyya na asali. Don haka wannan lokacin za mu gabatar da aikace-aikace na yau da kullun na Be-Cu infrared femtosecond Laser a masana'antu.

Laser Cutting Ultra- Thin Glass (UTG)

A halin yanzu, an yi amfani da kayan gilashin bakin ciki sosai a cikin nunin kayan lantarki na mabukaci da masana'antar semiconductor. Misali, gilashin da ke cikin filayen OLED ɗinmu da aka saba amfani da shi shine gilashin bakin ciki (UTG).

Tare da ci gaba da haɓaka fasahar wayar hannu, allon wayar hannu yana ƙara ƙarami kuma yana ƙara bambanta, kuma fasahar naɗewa ta fito kamar yadda lokutan ke buƙata. Koyaya, wayoyin hannu masu nadawa suna da babban buƙatu don gilashi. Mafi ƙarancin gilashin, mafi kyawun aikin watsa haske, mafi kyawun sassauci, kuma mafi ƙarancin nauyi. Duk da haka, irin wannan nau'in Laser Laser Yanke yana buƙatar babban daidaito, inganci mai kyau, babu micro-cracks, babu fashewar duhu, da dai sauransu. Saboda haka, Laser Laser Yanke gilashin lantarki ya zama babban hanyar yanke Laser a halin yanzu, kuma a matsayinmu na mu. Abubuwan buƙatu don guntuwar gefuna da ƙananan fashe suna ƙaruwa, , Laser femtosecond a hankali ya zama mafi kyawun zaɓi.

Yanke Laser na Femtosecond yana da matsanancin ƙarfin ƙarfi kuma yana iya ƙetare iyakar lalacewar gilashi cikin sauƙi; a lokaci guda, ultra-bakin gilashin ya fi kula da zafi, kuma bugun jini na femtosecond shine yanayin "Cold Laser Cutting", wanda zai iya sa gefen hasken ta zama cikakke, hasken haske ba sa tsoma baki tare da juna, kuma cimma nasara. Tasirin karaya mai ƙarancin ƙarfi: Yayin aikin Yankan Laser, bangon gefe yana iya zama santsi, guntuwar da ba a saba bi ka'ida ba ba ta da yuwuwar faruwa, kuma ɓarna da zafi mai yawa ke haifarwa ba sa iya faruwa. Ba shi da tasiri akan radius na lanƙwasawa na UTG kuma yana iya haɓaka rayuwar lanƙwasawa.

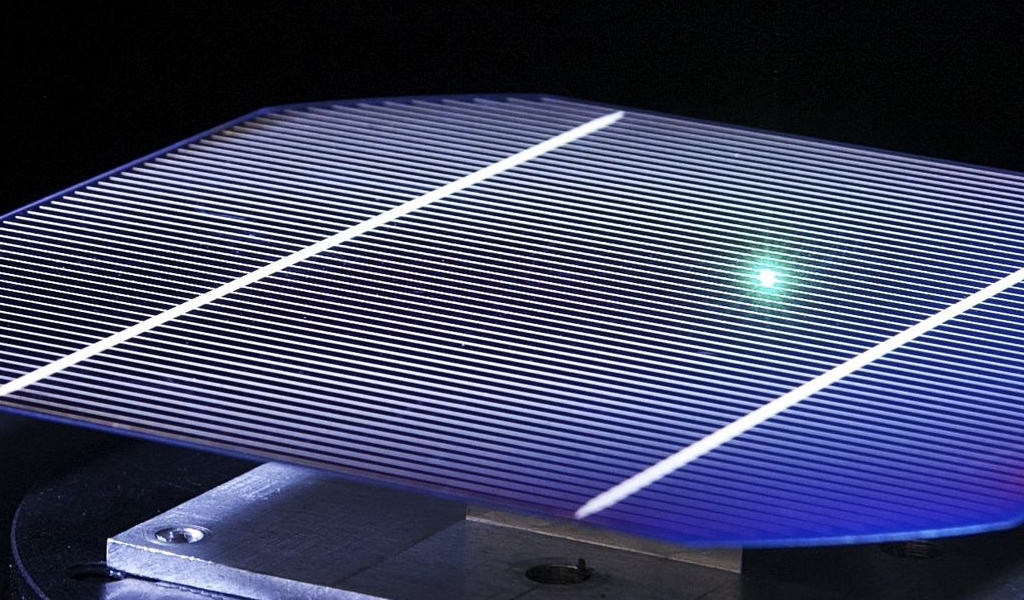

Laser Yankan Zinari-Plated Copper Foil

Rufin tagulla yana ɗaya daga cikin abubuwan da aka saba amfani da su a cikin masana'antar lantarki. Electrolyte shi ne mummunan electrolyte wanda aka ajiye a cikin wani Layer a kan madaurin allo kuma yana aiki a matsayin jagoran lantarki na hukumar. Bakin jan karfe samfurin jan ƙarfe ne na bakin ciki sosai. Copper iri daya ne da takarda kuma kaurinsa ma microns ne. Yawancin lokaci 5um-135um, da bakin ciki da fadi da wuya ya yi. A taƙaice, an matse foil ɗin jan ƙarfe a cikin zanen gadon sirara.

Ana amfani da foil ɗin tagulla sosai ta kowane fanni, kamar motocin lantarki, na'urorin lantarki, sararin samaniya, kayan sadarwa da sauran fannoni. Hanyar yankan Laser na gargajiya galibi yanke-yanke ne, amma akwai nakasu cikin inganci, saurin yankan Laser, asara da yanke daidaito. Lokacin amfani da yankan Laser na yau da kullun, tasirin thermal yana da girma. Tasirin thermal akan gefuna yana sa foil ɗin tagulla mai sauƙi don jujjuyawa da lalacewa, kuma gefuna suna da carbonized, yana haifar da lalata kayan abu.

Laser na femtosecond yana da fa'idodi da yawa a cikin Laser Yankan bangon jan karfe saboda yanayin sa na musamman na “Cold Laser Cutting”. Laser Femtosecond yana da kunkuntar bugun bugun jini, wanda zai iya sarrafa kayan tare da tasirin zafi kaɗan kaɗan, yana guje wa lalata kayan da ke haifar da tarawar zafi, da kyau yana ba da kariya ga faɗuwar zinari daga faɗuwa;

A lokacin aiwatar da yankan kai tsaye, ba za a sami launi ba, babu narkewa, babu gurɓataccen abu, da dai sauransu; da femtosecond Laser yana da kyakkyawan ingancin fitarwa. Bayan mayar da hankali, zai iya tabbatar da daidaiton tasirin gefen kayan da aka sarrafa da kuma hanyar yankewa. , Lalacewa a bangarorin biyu na ƙarshen fuska yana ba da damar yankan da gaske; Har ila yau, yana goyan bayan fashe da yawa da ayyukan gyaran bugun jini, yana ƙara haɓaka haɓakar Laser Cutting da tasiri.

Laser Yankan Zirconia Ceramics

Dangane da tukwane, abubuwan yumbura na zirconia (YSZ) suna da kyakkyawan juriya na zafin jiki kuma ana iya amfani da su azaman bututun ɗumamawa, kayan haɓakawa, da abubuwan dumama. Kuma yana da ma'auni na aikin lantarki mai mahimmanci, babban tauri, babban ƙarfin sassauƙa da juriya mai girma, kyawawan kaddarorin haɓakar thermal, haɓaka haɓakar thermal da sauran fa'idodi kusa da ƙarfe. An fi amfani dashi a cikin wuƙaƙen yumbu, na'urori masu auna sigina na oxygen, abubuwan thermal don sel mai, Solid oxide sel da abubuwan dumama zafin jiki, da sauransu.

Idan aka kwatanta da karafa, zirconia tukwane suna da fa'idodin mafi kyawun juriya na lalacewa, ƙasa mai santsi, rubutu mai kyau, kuma babu iskar shaka. Yawancin sanannun manyan kamfanoni kuma sun ƙaddamar da manyan agogon yumbura, suna mamaye wani wuri a cikin filin lalacewa mai wayo; yumbun ferrules da hannayen riga kuma ana amfani da su sosai a fagen fiber na gani masu haɗawa; a lokaci guda, yumbu na zirconia ba su da garkuwar sigina, suna da rigakafin digo, juriya, kuma Yana da fa'idodin nadawa, yanayin dumi da santsi, da jin daɗin hannu mai kyau, kuma ana amfani dashi sosai a cikin filayen lantarki na 3C kamar wayar hannu. wayoyi. Koyaya, yayin yankan Laser na yumbu na gargajiya na zirconia, babu makawa akwai jerin matsaloli kamar rashin ingancin Laser Cutting da ƙarancin ingancin Laser Cutting. Wannan yana buƙatar amfani da Yankan Laser na femtosecond, wanda zai iya magance wannan matsala daidai da inganci.

Saboda babban makamashi kololuwa na femtosecond bugun jini, sanyi Laser Yankan yanayin za a iya gane, wanda zai iya mafi cika da m bukatun na kayayyakin. A lokacin samfurin Laser Yanke, femtosecond Laser yana cinye ƙasa da makamashi kuma yana haifar da ƙarancin lalacewa ga kayan, don haka daidaiton Yankan Laser yana da girma; Laser Cutting Laser ba na al'ada ba na injin injiniya ba shi da damuwa kuma an rarraba shi daidai a gefen samfurin. Chipping yumbu ba shi da yuwuwar faruwa a cikin yanayin narkewa kuma ingancin ya fi kyau. Laser na femtosecond yana da ƙarfin ƙarfin ƙarfi sosai yayin aikin Yankan Laser kuma yana iya samun ingantacciyar damar yankewa don kayan yumbu na zirconia. , mai iya saurin yanke sifofin kayan abu zuwa siffa.

Ƙarin aikace-aikacen gwaji suna tabbatar da manyan fa'idodin fasahar yanke Laser na femtosecond (tare da stent da hypotube Laser sabon) a fagen masana'antu. Be-Cu kuma yana noma shi koyaushe, yana haɓaka ayyukan gwaji na aikace-aikacen don ba da cikakkiyar wasa zuwa ƙarin fa'idodin femtosecond da ci gaba da samar da Sauyi da haɓaka masana'antun masana'antu na ci gaba yana kafa tushe mai ƙarfi da haɓaka haɓakawa.

3, 4 da 5-daidaici axis Cibiyar CNC ayyuka na kayan aikin aluminum, beryllium, carbon carbon, magnesium, kayan aikin titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite da itace. Mai iya sarrafa sassa har zuwa 98 in. Juyawa dia. da +/- 0.001 a. haƙuri madaidaiciya. Ayyuka sun haɗa da niƙa, juyawa, hakowa, m, zare, taɓi, ƙirƙira, dunƙulewa, murƙushewa, ƙididdigewa, sakewa da yankan laser. Sabis na sakandare kamar taro, nika marar tsakiya, maganin zafi, plating da walda. Samfurin samfuri da ƙarami zuwa ƙarar girma da aka bayar tare da matsakaicin raka'a 50,000. Ya dace da ikon ruwa, pneumatics, hydraulics da bawul aikace -aikace. Yana aiki da sararin samaniya, jirgin sama, soja, likitanci da masana'antun tsaro.PPJ zai yi dabarun yin aiki tare da ku don samar da mafi kyawun sabis masu tsada don taimaka muku isa ga burin ku, Barka da zuwa Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

3, 4 da 5-daidaici axis Cibiyar CNC ayyuka na kayan aikin aluminum, beryllium, carbon carbon, magnesium, kayan aikin titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite da itace. Mai iya sarrafa sassa har zuwa 98 in. Juyawa dia. da +/- 0.001 a. haƙuri madaidaiciya. Ayyuka sun haɗa da niƙa, juyawa, hakowa, m, zare, taɓi, ƙirƙira, dunƙulewa, murƙushewa, ƙididdigewa, sakewa da yankan laser. Sabis na sakandare kamar taro, nika marar tsakiya, maganin zafi, plating da walda. Samfurin samfuri da ƙarami zuwa ƙarar girma da aka bayar tare da matsakaicin raka'a 50,000. Ya dace da ikon ruwa, pneumatics, hydraulics da bawul aikace -aikace. Yana aiki da sararin samaniya, jirgin sama, soja, likitanci da masana'antun tsaro.PPJ zai yi dabarun yin aiki tare da ku don samar da mafi kyawun sabis masu tsada don taimaka muku isa ga burin ku, Barka da zuwa Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan