Hanyoyi 10 don sanin yadda ake yin 3D bugu

Kuna buƙatar kula da waɗannan shawarwari guda 10 lokacin yin samfuri

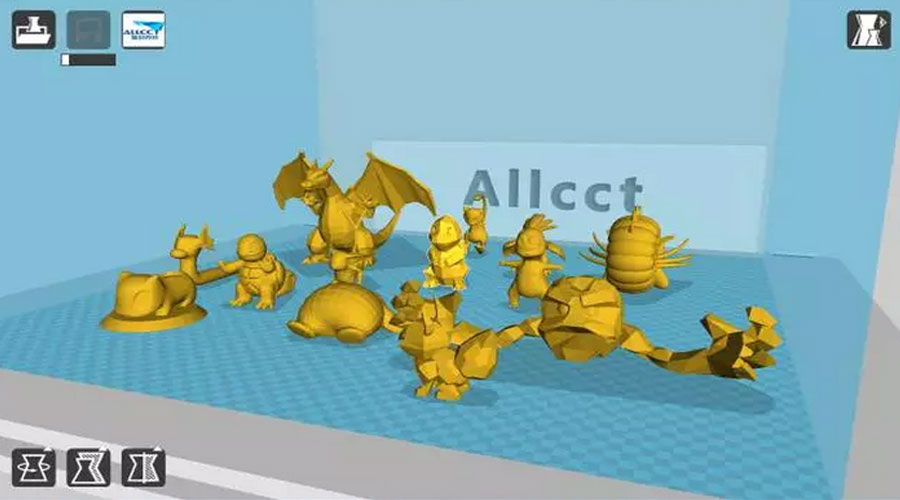

| Ba duk samfura ba ne za a iya amfani da su don buga 3D. Samfuran halayen wasan kan layi suna da kyau sosai, amma a zahiri yawancin ba za a iya amfani da su ba, me yasa? Saboda manufar ƙirar ƙirar ƙira ba don bugu na 3D ba ne, don haka wurare da yawa ba a tsara su bisa ga buƙatun samfuran bugu na 3D ba. |

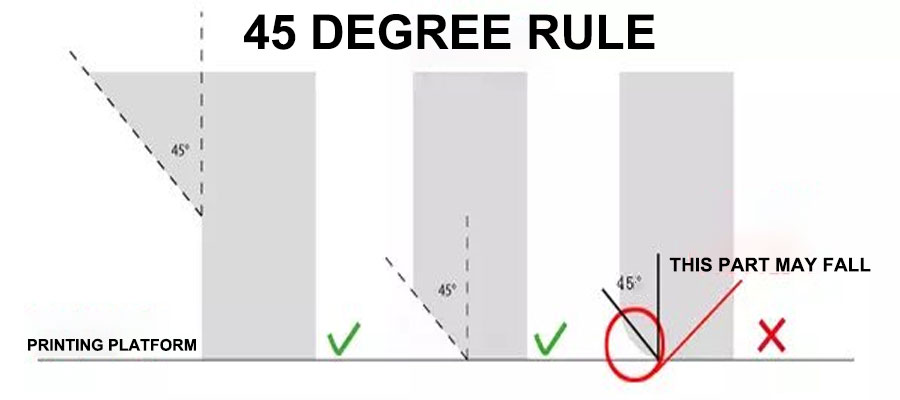

1. 45 digiri mulki

A cikin samfurin gaba ɗaya, fiye da digiri 45 na sassa masu tasowa suna buƙatar tallafi lokacin bugawa. Don haka, lokacin da muke yin samfuri, yi ƙoƙarin guje wa fitowar babban kusurwa.

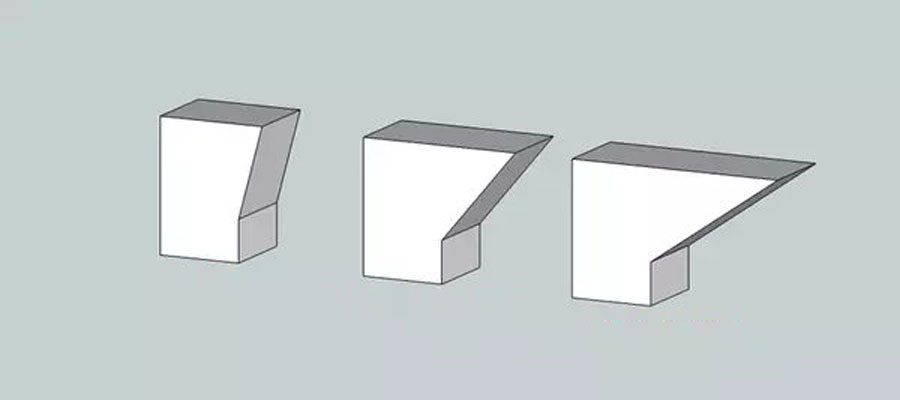

2. Inganta ƙira tare da ƙarancin tallafi

Zafin goyon baya da goyon baya ne kawai aka sani bayan kwarewa na sirri, kuma bayan an kammala goyon baya, har yanzu yana barin alama mai banƙyama a kan samfurin, kuma tsarin cire alamun yana ɗaukar lokaci da wahala.

A gaskiya, ba kwa buƙatar ƙara tallafi. Lokacin da kake duban ƙirar ƙira, dole ne ka ƙara yin aiki tuƙuru. Kuna iya tsara tallafi ko haɗin gwiwa don sassan da dole ne a haskaka su don rage damar tallafi.

Wannan yana adana matsalar ƙara tallafi, goyan baya da goge sassan tallafi. Tabbas, samfurin ba zai iya guje wa goyon baya ba, kuma za'a iya ƙara shi kawai a fatar kan mutum.

3. Yi ƙoƙarin tsara tushen buga rubutun ku

Babban yanki na lamba tsakanin kasan samfurin da dandamali zai iya rage girman curling yadda ya kamata, kamar sanannun "kunnen linzamin kwamfuta".

Kamar yadda aka nuna a ƙasa, wannan tushe ne mai siffar faifai ko mazugi wanda ke ƙara kamawa.

Tabbas, zaku iya amfani da siket da raft a cikin software na yanka don rage curl. Duk da haka, ba a ba da shawarar ba, zai ja saukar da lokacin buga ku, kuma yana da wuya a cirewa da lalata ƙasan samfurin.

4. Fahimtar iyakokin firinta

Dangane da yanayin firintar ku, ingantaccen ƙirar ƙirar, kamar yin amfani da firinta na FDM don buga ƙarin cikakkun samfuran hannu, babu shakka yana neman haushi, don tallafawa, datsa sasanninta....

Domin sauƙaƙe bugu na 3D, kuna buƙatar kula da waɗannan tukwici 10 lokacin yin samfuri.

5. Haƙiƙa saita haƙuri

Samfurin da talakawan tebur 3D printer ya buga yana da wasu kurakurai, musamman sassa masu motsi, ramukan ciki da makamantansu.

Don mafi girman madaidaicin buƙatun, yakamata a saita haƙuri da kyau lokacin zayyana samfurin. Misali, rami na ciki yana ba da adadin diyya. Don nemo haƙƙoƙin da ya dace ya fi damuwa, kuna buƙatar taɓa "zafin" na injin ku.

6. Matsakaicin amfani da harsashi (Shell)

A wasu samfura masu madaidaicin buƙatun, kar a yi amfani da yawa lokacin saita harsashi, musamman idan an buga saman da ƙananan haruffa. Idan an saita harsashi da yawa, zai ɓata waɗannan cikakkun bayanai.

7. Yi amfani da faɗin layi da kyau

Lokacin kunna firintocin 3D, akwai mahimmanci mai mahimmanci amma sau da yawa ba a kula da shi ba, wanda shine faɗin layin. An ƙayyade faɗin layin ta hanyar diamita na bututun bugawa, kuma yawancin nozzles na firintocin suna da diamita 0.4mm.

Lokacin buga samfurin don zana da'ira, ƙaramin da'irar da firinta zai iya zana shine ninki biyu na faɗin layin, kamar bututun ƙarfe na 0.4mm, ƙaramin da'irar da za a iya zana, kuma diamita shine 0.8mm.

Don haka yi amfani da faɗin layin da kyau lokacin yin samfuri. Idan kana son yin wasu samfura waɗanda za a iya lanƙwasa ko sirara, yana da kyau a tsara kaurin ƙirar ku azaman faɗin layi.

8. Daidaita yanayin bugawa don mafi kyawun daidaito

Don firintocin FDM, zaku iya sarrafa daidaito kawai (kaurin Layer) a cikin jagorar Z-axis saboda an ƙaddara daidaiton jagorar axis XY ta faɗin layin.

Idan samfurin ku yana da ɗan ƙira mai kyau, yana da kyau a bincika idan yanayin bugun samfurin yana da ikon buga kyawawan abubuwa. Ana ba da shawarar buga waɗannan cikakkun bayanai a cikin hanyar Z-axis (a tsaye).

Lokacin zayyana samfurin, cikakkun bayanai kuma an fi sanya su a cikin wani wuri inda yana da sauƙin bugawa a tsaye. Ba ya aiki, zaku iya yanke samfurin don bugawa sannan ku sake haɗawa.

9. Daidaita jagorar bugawa don jure matsi

Lokacin da bugu ya buƙaci jure wa wani adadin matsa lamba, dole ne ku tabbatar da cewa samfurin ba zai lalace ko karye ba, kuma dole ne ku yi tasiri na dogon lokaci lokacin yin samfuri da bugu.

Lokacin yin samfuri, zaku iya yin kauri daidai da matsayi a ƙarƙashin matsi gwargwadon jagorancin ƙarfin. Lokacin bugawa, ana yin bugu a tsaye a cikin hanyar Z-axis, kuma mannewa tsakanin yadudduka yana iyakance, kuma ikon jurewar matsa lamba ba shi da kyau kamar bugu a cikin axis na XY.

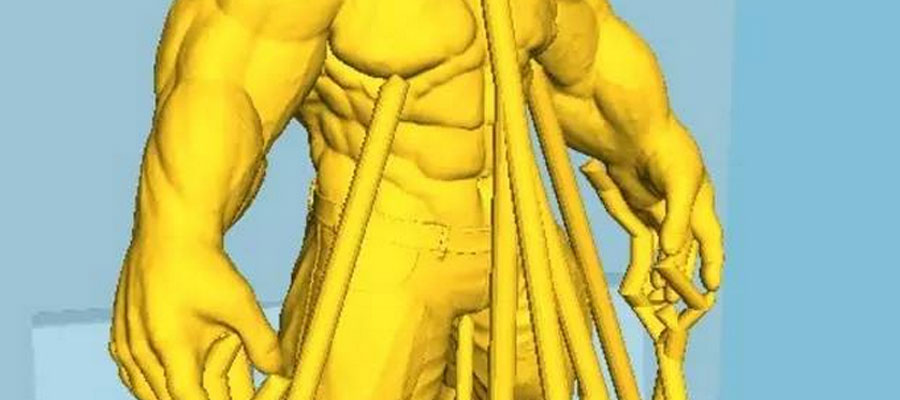

10. Sanya samfurin ku daidai

Lokacin bugawa, sanya samfurin kuma tambaya ce ta jami'a. Bugu da ƙari, daidaitawa na bugu da aka ambata a sama, dole ne ku kula da matsayi na matsayi kuma ku rage damar da za ku iya tallafawa.

Har ila yau, idan an buga adadi mai yawa na samfurori tare, sanyawa na samfurin yana buƙatar kula da tazara. Ba lallai ba ne abu mai kyau a kusanci ma.

Shiga wannan labarin : Hanyoyi 10 don sanin yadda ake yin 3D bugu

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan