Yadda ake cire burrs daga machining

Menene Burrs?

| Burr - yana nufin extrusion nakasar kayan ƙarfe yayin aiki. An samar da ƙarin tarkacen ƙarfe a gefen samfurin, wanda aka fi sani da filashi, yayin yankan, niƙa, niƙa, da sauran sarrafa guntu irin wannan. na. |

1. A ko'ina da illar bursu

Burrs samfurori ne da babu makawa na sarrafa ƙarfe kuma suna da wahala a guje su gaba ɗaya. Kasancewar burrs ba wai kawai yana rinjayar bayyanar samfurin ba, har ma yana rinjayar taro da yin amfani da samfurin, yana hanzarta lalacewa tsakanin na'urorin, kuma yana rage rayuwar sabis. Tare da haɓaka fasaha mai girma da haɓaka aikin samfur, abubuwan da ake buƙata don ingancin samfurin suna ƙara tsanantawa, kuma kawar da burbushin sassa na inji ya zama mafi mahimmanci. Kasancewar burrs yana da babban tasiri akan ingancin samfura da haɗuwar samfur, amfani, daidaiton girman, da daidaiton siffar. Mahimmanci, duk samfurin an goge shi kuma gabaɗayan injin ɗin ba za a iya sarrafa shi ba.2. Yadda za a cire burrs?

Ya zuwa yanzu, hanyar da za a magance burr: kawai bayan ƙarshen aikin samfurin, ƙara tsarin cire burr. Akwai manyan hanyoyi guda biyu don cire burrs: kawar da sinadarai da kuma cirewar jiki. Ana amfani da sinadarai galibi don madaidaicin core workpieces tare da hadaddun siffofi, nakasu, babban madaidaicin buƙatun da babban aikin farashi. Ana amfani da ajin jiki don sassa tare da ƙasa mai ƙazanta da ƙananan buƙatun daidaito masu sauƙi waɗanda ke da sauƙin cirewa ta aikin hannu.

Tsarin lalata sinadarai tsari ne na jiƙa wanda ke samun tasirin cire burrs ta hanyar jiƙa. Tsarin ya samo asali ne daga Jamus. A tsari ne yadu amfani a mota, Aerospace, karfe sassa aiki, da dai sauransu. Dace workpieces ne kullum m sassa; stam sassa; sassa bututun mai; sassa na yadi; kaya sassa; ɗauka sassa; Na'urori; ɗauka sassa; sassan watsawa; ɗaukas; Cibiyar CNC sassa, da dai sauransu, da tsari ne yafi amfani da bambanci tsakanin burr da tsarin da workpiece kanta, ta hanyar ka'idar a tsaye dauki, don cimma sakamakon deburring. Ma'anar mu na burrs yana nufin cewa kauri na burr bai wuce 20 filaments ba, wanda ba shi da dangantaka da tsayin burr.

Idan aka kwatanta da ɓarna na gargajiya, tsarin yana da nisa fiye da tsarin al'ada dangane da aminci, maimaitawa, kwanciyar hankali da kare muhalli; yana da inganci kuma yana adana lokaci, yana haɓaka ƙarshen samfurin, yana da aminci kuma abin dogaro, kuma yana da alaƙa da muhalli. Aiki mai sauƙi ne kuma yana iya haɓaka ƙarfin lalata da haɓakar samfur.

Bacewar jiki yafi hada da: m (hard lamba) yankan, nika, m, scraping, general sa (laushi lamba), abrasive bel nika, nika, roba nika, polishing da sarrafa, da sauran daban-daban digiri na aiki da kai. Sana'a. Yawancin kayan aikin da ake sarrafa ba su da garanti; farashin samarwa da farashin ma'aikata suna da yawa sosai.

Lokacin zabar hanyar yanke hukunci, ya kamata mu yi la'akari da dalilai daban-daban, kamar kayan kayan, sifar tsarin, girman da daidaiton sassan, ba da kulawa ta musamman ga tasirin ɓacin rai, juriya mai juzu'i, nakasawa da damuwa na saura.

3. Bari mu ga abin da masu amfani da yanar gizo ke cewa game da glitch!

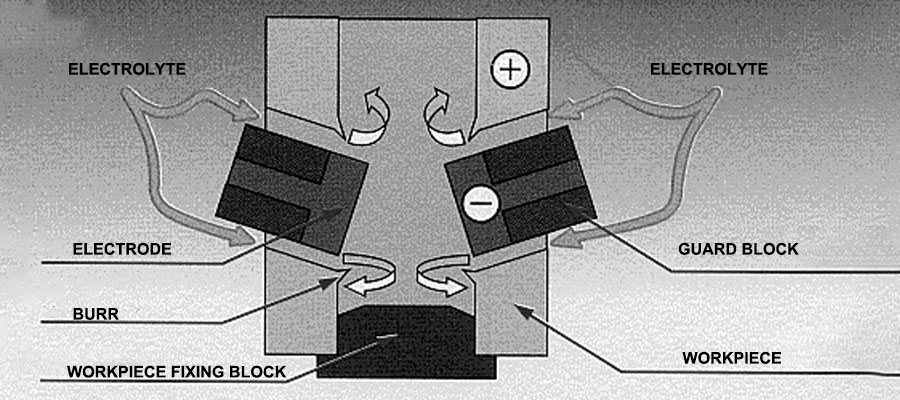

Netizen 1: The electrolyte a cikin electrolytic deburring yana da wasu lalata, kuma workpiece ya kamata a tsabtace da tsatsa-proofed bayan deburring. Electrolytic deburring ya dace don cire burrs na ɓoyayyun sassa ko sassa masu siffa a cikin sassa, ingantaccen samarwa da ɗan gajeren lokaci. Wannan hanyar ta dace da gears, splines, sanduna masu haɗawa, bawul jiki da crankshasha madogaran mai. Irin su burrs, da kuma kusurwoyi masu zagaye da sauransu. Rashin hasara shi ne cewa abin da aka makala na burr na ɓangaren kuma yana ƙarƙashin electrolysis, kuma saman zai rasa ainihin haske kuma har ma yana rinjayar daidaiton girman.

Netizen 2: Glitches, mutanen da suka yi gwagwarmaya a masana'antar karfe dole ne su san shi. A cikin sarrafa kayayyakin karfe, yana da yawa a ko'ina. Ko ta yaya ingantattun kayan aikin da kuke amfani da su, za a samar da su tare da samfuran.

Netizen 3Hanyar ɓatar da hannu: 1. Shirya kayan aiki kamar sassa da fayilolin gami da za a cire su. 2. Riƙe fayil ɗin da hannunka kuma taɓa gefen burar. Juya 5-10 digiri. Za a zazzage saman cikin sauƙi. Idan kusurwa ya yi girma sosai, za a yi wa gefen gefen. 3. Yi amfani da ɗan ƙarfi don niƙa burrs kuma kammala ɓarnawar gabaɗayan sashin a cikin wani tsari, kamar gaba da baya. 4. Duba idan an cire burrs.

Netizen 4: Abin da ake kira burr, yawanci nakasar filastik na kayan da kuma karin kayan ƙarfe da aka samar a gefen kayan da aka sarrafa, musamman ma kayan da ke da kyau ko tauri, yana da haɗari ga burrs, kuma matsalar burr ita ce Daya. daga cikin kalubalen da masana'antar karafa ta kasa magancewa kawo yanzu.

Netizen 5: Hanyar sarrafa electrolytic don cire burrs na karfe sassa ta hanyar electrolysis, wato, ajiye kayan aiki cathode (yawanci tagulla) a cikin kusanci da burr na workpiece, wanda aka rabu da wani rata (gaba daya 0.3-1) Mm). . Sashin gudanarwa na cathode na kayan aiki yana daidaitawa tare da gefen burr, kuma sauran sassan an rufe su da rufin rufi don maida hankali kan electrolysis akan sashin burr. A lokacin aiki, da workpiece cathode an haɗa zuwa korau iyakacin duniya na wutar lantarki DC, da kuma workpiece an haɗa zuwa tabbatacce iyakacin duniya na wutar lantarki DC A low matsa lamba electrolyte (yawanci sodium nitrate ko ruwa sodium chlorate) da matsa lamba na 0.1. -0.3 MPa yana gudana tsakanin workpiece da cathode. Lokacin da aka kunna wutar DC, burr yana narkar da shi kuma an cire shi, kuma electrolyte ya ɗauke shi.

Netizen 6: Bayan an wanke saman bayan an nika, ko da yake yana da kyau sosai, amma wasu daga cikin fitattun fitattun masu kaifi ba sa kasa, sai dai a lankwashe su a baje a saman bangaren. A ƙarƙashin tip ɗin da aka lanƙwasa, an rufe sararin samaniya da yawa, kuma babu makawa cewa ruwa da iska za su kasance cikin waɗannan wurare. Danshi a cikin keɓaɓɓen sararin samaniya yana sa iska ta yi tsatsa, kuma a ƙarƙashin wasu yanayi, an sake fadada sararin samaniya. Wannan wani muhimmin dalili ne na lalata da rashin daidaito bawon rufin ko wasu yadudduka masu kariya bayan wani lokaci. Tsarin Cullygrat, ta hanyar amsawar syrup tare da sassan, yana aiki a kai tsaye zuwa saman, don haka yana guje wa tsarar wuraren da aka kulle. Bugu da ƙari, ta hanyar inganta ƙaddamarwa, ƙarfin daɗaɗɗen ɓangaren don tsayayya da kaya yana inganta sosai.

Shiga wannan labarin : Yadda ake cire burrs daga machining

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis masu saurin daidaitaccen kayan aikin CNC ciki har da niƙa, juyawa zuwa ƙayyadadden abokin ciniki, Caparfin ƙarfe & kayan aikin filastik tare da haƙurin +/- 0.005 mm.mutu Fitar,karfe Samar da samfura, cikakken kayan aiki, gudummawar fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis masu saurin daidaitaccen kayan aikin CNC ciki har da niƙa, juyawa zuwa ƙayyadadden abokin ciniki, Caparfin ƙarfe & kayan aikin filastik tare da haƙurin +/- 0.005 mm.mutu Fitar,karfe Samar da samfura, cikakken kayan aiki, gudummawar fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan