Bincike kan sabon yanayin ci gaban fasaha na maganin zafi don masu ɗaurin mota

1. Sakamakon tsarin maganin zafi akan inganta ƙarfin gajiyar kusoshi

Na dogon lokaci, mota ɗaukas an mamaye da asali halaye na da fadi da kewayon iri, iri, da kuma bayani dalla-dalla. Zaɓin zaɓinsa da amfani da shi sun haɗa da bincike na tsari, ƙirar haɗin gwiwa, gazawa da bincike na gajiya, buƙatun lalata da hanyoyin haɗuwa, da kuma abubuwan da suka danganci waɗannan abubuwan suna tabbatar da ingancin ƙarshe da amincin samfuran kera zuwa babban matsayi.

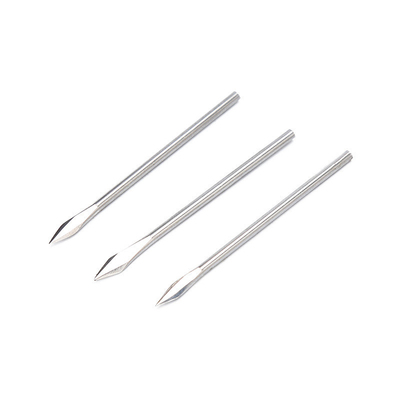

Rayuwar gajiyawar ƙwanƙwasa masu ƙarfi na motoci koyaushe ya kasance muhimmin batu. Bayanai sun nuna cewa mafi yawan kasawar kusoshi na faruwa ne sakamakon gazawar gajiya, kuma kusan babu alamar gajiyawar kullin. Don haka, ana iya samun manyan hatsarori idan gazawar gajiya ta auku. Maganin zafi zai iya inganta kaddarorin kayan fastener kuma ƙara ƙarfin gajiyarsu. Dangane da karuwar buƙatun amfani da ƙwanƙwasa masu ƙarfi, yana da mahimmanci don inganta ƙarfin gajiyar kayan aiki ta hanyar maganin zafi.

1. Farawar gajiya ta fashe a cikin kayan

Wurin da gajiya ta fara tsagewa ana kiranta tushen gajiya. Tushen gajiya yana da matuƙar kula da ƙaramin tsari na kusoshi, kuma yana iya fara faɗuwar gajiya a ƙaramin ma'auni, gabaɗaya tsakanin girman hatsi 3 zuwa 5. Ingancin saman kullin shine babban matsala. Tushen gajiya, yawancin gajiyar yana farawa ne daga bangon kulle ko ƙasa. Babban adadin tarwatsewa, wasu abubuwa masu haɗawa ko ƙazanta a cikin kristal na kayan aron ƙarfe, da bambancin ƙarfin iyakar hatsi na iya haifar da farawa fashe gajiya. Nazarin ya nuna cewa gajiyar gajiya suna da wuyar faruwa a wurare masu zuwa: iyakokin hatsi, abubuwan da aka haɗa a sama ko ɓarna na lokaci na biyu, da cavities. Waɗannan wuraren duk suna da alaƙa da haɗaɗɗiyar ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwa. Idan za'a iya inganta microstructure bayan maganin zafi, ana iya inganta ƙarfin gajiyar abin rufewa zuwa wani matsayi.

2. Sakamakon decarburization akan ƙarfin gajiya

Ƙarƙashin ɓangarorin abin rufe fuska zai rage taurin saman da kuma sa juriya na kulle bayan quenching, kuma yana rage ƙarfin gajiyar kullun. Akwai gwajin decarburization don aikin bolt a cikin ma'aunin GB/T3098.1, kuma an kayyade matsakaicin zurfin decarburization. Lokacin da ake nazarin dalilan gazawar 35CrMo hub bolts, an gano cewa akwai wani yanki da aka lalatar da shi a mahadar zaren da sandar. Fe3C zai iya amsawa tare da O2, H2O, da H2 a yanayin zafi mai zafi don rage Fe3C a cikin kayan da aka rufe, ta haka yana ƙara yawan lokaci na ferrite na abin da ke rufewa, rage ƙarfin abin da ke ciki, da kuma haifar da ƙananan ƙwayoyin cuta. A cikin tsarin maganin zafi, dole ne a kula da zafin jiki mai zafi da kyau, kuma a lokaci guda, dole ne a yi amfani da dumama kariyar yanayi mai sarrafawa don magance wannan matsala.

3. Sakamakon maganin zafi akan ƙarfin gajiya

Ƙaddamar da damuwa a saman kullun zai rage ƙarfinsa. Lokacin hõre alternating tsauri lodi, da aiwatar da micro-nakasawa da kuma dawo da zai ci gaba da faruwa a cikin danniya taro na daraja, da kuma danniya ta yi na'am da shi ne mafi girma daga cikin kashi ba tare da danniya da taro, don haka shi ne mai sauki kai ga tsarar gajiya ta fasa.

Fasteners suna da zafi-bi da zafi don inganta microstructure, kuma suna da kyawawan kayan aikin injiniya masu kyau, wanda zai iya inganta ƙarfin gajiya na kayan ƙwanƙwasa, da dacewa da sarrafa girman ƙwayar hatsi don tabbatar da ƙarfin tasiri na ƙananan zafin jiki, da kuma samun ƙarfin tasiri mafi girma. Ma'anar zafi mai ma'ana don tace hatsi da rage nisa tsakanin iyakokin hatsi na iya hana fasa gajiya. Idan akwai takamaiman adadin barasa ko barbashi na biyu a cikin kayan, waɗannan ƙarin matakan na iya hana mazaunin zama zuwa wani ɗan lokaci. Zamewar bel yana hana farawa da fadada microcracks.

2. Quenching matsakaici da matsakaicin sarrafawa don maganin zafi

Motoci masu ƙarfi masu ƙarfi suna da jerin fasalulluka na fasaha: madaidaicin ma'auni; yanayin sabis mai tsanani, zai yi tsayayya da tasirin sanyi mai tsanani da matsanancin zafin jiki a duk shekara tare da mai watsa shiri, da kuma tsayayya da yashwar yanayin zafi da ƙananan zafi; Matsayi mai tsayi, nauyi mai ƙarfi, nauyi mai nauyi, nauyi mai nauyi da lalata kafofin watsa labarai na muhalli, ban da tasirin axial pre-tightening tensile load, Hakanan za'a sanya shi zuwa ƙarin ƙarin juzu'i na canzawa, juzu'i mai jujjuya nauyi ko haɗaɗɗen lankwasawa yayin aiki. Wani lokaci kuma yana fuskantar tasirin tasiri; ƙarin nauyin juzu'i na juyawa na iya haifar da kusoshi don sassautawa, kayan maye na axial na iya haifar da faɗuwar gajiyar kusoshi, kuma nauyin ɗaukar nauyi na axial na iya haifar da jinkirin karaya na kusoshi, da yanayin yanayin zafi. Guguwar kusoshi, da sauransu.

Yawancin kusoshi da suka gaza sun nuna cewa sun karye tare da sauye-sauyen da ke tsakanin ƙwanƙwasa da shasha a lokacin hidima; An ciro su tare da mahadar zaren kullin shasha da shasha; Kuma akwai ƙullun zamiya tare da ɓangaren zaren. Metallographic bincike: Akwai ƙarin ferrite da ba a narkar da su a saman da kuma ainihin abin rufewa, da rashin isasshen haɓakawa yayin kashewa, ƙarancin ƙarfin matrix da ƙaddamar da damuwa sune ɗayan mahimman dalilai na gazawar. A saboda wannan dalili, yana da mahimmancin hanyar haɗi don tabbatar da ƙaddamar da shinge na shinge da kuma daidaitattun tsarin.

Ayyukan man fetur na quenching shine a gaggauta cire zafi na ƙullun ƙarfe mai zafi da kuma rage su zuwa yanayin canjin martensite don samun babban tsarin martensite mai ƙarfi da zurfin Layer. Har ila yau, dole ne a yi la'akari da raguwar nakasar kusoshi da rigakafin Cracked. Sabili da haka, ainihin halayen quenching mai shine "halayen sanyaya", wanda ke nuna saurin sanyaya a cikin babban yanayin zafin jiki, da saurin sanyi a cikin ƙananan zafin jiki. Wannan halayyar ya dace sosai don buƙatun quenching na gami tsarin karfe ≥ 10.9 babban ƙarfin ƙarfi.

Man fetur mai saurin kashewa yana haifar da bazuwar thermal, oxidation da halayen polymerization yayin amfani, wanda ke haifar da canje-canje a cikin halayen sanyaya. Danshin da ke cikin mai zai yi tasiri sosai ga aikin sanyaya mai, wanda zai haifar da raguwar haske da rashin daidaituwar taurin na'urorin bayan quenching. Samar da tabo mai laushi ko ma daɗaɗɗen hali. Bincike ya nuna cewa matsalolin nakasar da ke haifar da kashe mai, wani bangare ne na ruwa da ke cikin mai. Bugu da ƙari, abubuwan da ke cikin ruwa a cikin mai kuma yana hanzarta haɓakawa da lalacewar man fetur kuma yana inganta gazawar abubuwan da ke cikin man. A lokacin da ruwan da ke cikin man ya fi ko kuma ya kai kashi 0.1%, idan man ya yi zafi, ruwan da aka tattara a kasan tankin mai na iya fadada girma kwatsam, wanda hakan na iya sa man ya cika tankin da ke kashewa, ya kuma haifar da cikas. wuta.

Don saurin kashe man da aka yi amfani da shi a cikin tanderun bel ɗin ci gaba, dangane da bayanan halayen quenching da aka tara a cikin gwajin tazara na watanni 3, yana yiwuwa a tabbatar da kwanciyar hankali da halayen quenching na mai, ƙayyade rayuwar sabis ɗin da ta dace na quenching. mai, da kuma hasashen aikin man da ke kashewa. Canza matsalolin da ke da alaƙa, ta haka rage sake yin aiki ko asarar sharar gida sakamakon canje-canje a cikin kashe kaddarorin mai, mai da shi hanyar sarrafawa ta al'ada don samarwa. Zurfin hardening kai tsaye yana rinjayar ingancin kullun bayan maganin zafi. Lokacin da hardenability na kayan ya kasance matalauta, yawan sanyaya na matsakaiciyar sanyaya yana jinkirin, kuma girman guntu yana da girma, ba za a iya kashe ƙwanƙwasa ba a cikin martensite a lokacin quenching. Ƙungiyar ta rage ƙarfin ƙarfin yankin zuciya, musamman ƙarfin yawan amfanin ƙasa. Wannan ba shakka yana da matukar lahani ga ƙwanƙwasa waɗanda ke ɗauke da nau'ikan damuwa iri ɗaya iri ɗaya tare da duka ɓangaren giciye. Rashin isasshen ƙarfi yana rage ƙarfi. Binciken metallographic ya gano cewa akwai proeutectoid ferrite da tsarin ferrite da aka tsinkaya a cikin ainihin, yana nuna cewa ƙarfin ƙulla yana buƙatar ƙarfafawa. Kamar yadda muka sani, akwai hanyoyi guda biyu don ƙara ƙarfin ƙarfi don ƙara yawan zafin jiki; ƙara hardenability na quenching matsakaici, wanda zai iya yadda ya kamata ƙara hardening zurfin aron.

Houghto-Quench ya samar da man fetur na musamman mai saurin kashewa dangane da ainihin man da ke kashe matsakaicin matsakaiciyar sauri, Houghto-Quench G. Houghto-Quench K2000 ya kara inganta karfin taurinsa, kuma ya dace musamman don amfani da shi wajen kashewa da sanyaya na'urar fasteners. Mai gamsarwa zurfin taurin.

Matsayin fim ɗin tururi na mai saurin kashewa yana da ɗan gajeren lokaci, wato, yanayin yanayin zafin mai yana yin sanyi da sauri. Wannan yanayin yana da kyau don samun zurfin taurara mai zurfi don 10B33 da 45 karfe ≤ M20 bolts da M42 kwayoyi, yayin da SWRCH35K da 10B28 karfe, an rage kawai lokacin da kauri ya kasa ko daidai da M12 bolts da M30 kwayoyi na iya taurin. na cibiya da taurin saman suna da ɗan bambanci. Daga nazarin rarraba adadin sanyaya, ban da saurin sanyaya da ake buƙata a cikin matsakaici da matakan zafi mai zafi, ƙananan zafin jiki na man fetur yana da tasiri mai zurfi a kan zurfin Layer mai tauri. Mafi girman ƙimar sanyi mai ƙarancin zafin jiki, zurfin daɗaɗɗen Layer. Wannan yana da fa'ida sosai ga maɗauran ƙarfi masu ƙarfi don ɗaukar kaya daidai gwargwado a duk faɗin sashin, kuma ana buƙatar samun kusan 90% na tsarin martensite kafin zafin jiki a cikin yanayin da aka kashe. Alamun kimar sun haɗa da kusan alamomi 20 kamar walƙiya, danko, ƙimar acid, juriya da iskar shaka, sauran carbon, ash, sludge, quenching sanyayawa, da quenching haske.

Don manyan kusoshi masu girma, PAG quenching wakili shine babban mafita, wanda ya dace da buƙatun quenching na yawancin samfuran. PAG quenching wakili yana cikin matakin tafasa a cikin yankin canjin martensite, kuma yawan sanyaya yana da girma kuma akwai haɗari mafi girma. Ana iya daidaita shi ta hanyar maida hankali. Matsakaicin sanyaya a maɓalli mai mahimmanci shine kusan 300 ℃. Ƙarƙashin yanayin sanyaya a wannan yanayin zafin jiki, ƙarfin ikon hana ɓarnawar ɓarna da ƙimar ƙarfe mafi dacewa. Kwanciyar kwanciyar hankali na convection lokacin amfani shine mafi mahimmancin abu don tabbatar da ingancin quenching.

A cikin samfurori na kusoshi na farko na gazawar, ana iya ganin cewa akwai lahani a kan zaren ɓangarorin da ke kusa da karaya. Babban dalili shi ne cewa kusoshi suna birgima ba daidai ba. Ya haifar da nadawa; Hakanan za'a iya ganin ƙananan ƙananan ƙananan zurfin daban-daban a cikin kasan zaren, kuma mashin da aka gina shi yana haifar da wani yanki na damuwa. Matsayin GB / T5770.3-2000 "Bukatun Musamman don Bolts, Screws da Studs tare da Lalacewar Surface akan Fasteners" ya nuna cewa folds waɗanda ba su wuce kashi ɗaya cikin huɗu na tsayin bayanin zaren sama da diamita na bolts a ƙarƙashin matsin lamba ba. an yarda Ba a yarda da nadawa da ginanniyar zaren kasa da lahani, kuma nadawa yana daya daga cikin manyan dalilan karaya. Yin amfani da matsananciyar matsi na Houghton don sarrafa zaren ƙulla zai iya hana ginannun gefen da kyau da kuma rage yawan damuwa, ta haka yana taimakawa wajen haɓaka rayuwar gajiyar kusoshi.

3. Kariyar sararin samaniya da haɓaka fasahar kera motoci

Fasteners a kan motoci, musamman bolts, clamps, na roba, da dai sauransu, suna cikin matsanancin yanayi yayin amfani da su, kuma yawanci suna lalata su da gaske, har ma da wuyar haɗuwa saboda tsatsa. Saboda haka, fasteners dole ne su kasance da kyawawan kaddarorin anti-lalata. Hanyoyin da aka fi amfani dasu a halin yanzu sune electro-galvanizing, zinc-nickel alloy, phosphating, blackening da kuma dacromet jiyya a saman. Sakamakon ƙuntatawa akan abun ciki na chromium hexavalent a cikin rufin saman na kayan haɗin mota, bai dace da ka'idodin ka'idodin kariyar muhalli ba, kuma samfuran da ke ɗauke da abubuwa masu cutarwa ba a yarda su shiga kasuwa ba, wanda ke sanya babban abin da ba a taɓa gani ba a cikin sabbin abubuwa. ikon fastener na mota surface jiyya Daidaitaccen buƙatun muhalli.

1. Ruwa na tushen tutiya-aluminum shafi Geomet

Environmentally-friendly sabon shafi fasaha-flake zinc-aluminum shafi Geomet, Enoufu Group ya ɓullo da wani cikakken fasaha bisa fiye da shekaru 30 na DACROMET surface anti-tsatsa fasaha kwarewa da kuma bayan shekaru na bincike da kuma ci gaba. Sabuwar fasahar jiyya ta saman chromium --- GEOMET.

Tsarin hana tsatsa, tsarin fim ɗin da Gummet ya yi masa ma daidai yake da fim ɗin Dacromet. Ƙarfe-ƙarfe suna cike da yadudduka don samar da fim ɗin da aka haɗe tare da manne na tushen siliki don rufe ma'auni.

Abũbuwan amfãni na Geomet: Ƙarfafawa, takardar ƙarfe mai ƙarfi mai ƙarfi yana sa kusoshi na Geomet su zama jagora. Daidaitawar fenti, Geomet za a iya amfani da shi azaman firamare don yawancin fenti gami da lantarki. Kariyar muhalli, bayani na tushen ruwa, ba ya ƙunshi chromium, kuma ba a samar da ruwan sharar gida ba, kuma ba a fitar da abubuwa masu cutarwa a cikin iska. Kyakkyawan juriya na lalata, kawai 6-8μm fim kauri, na iya isa gwajin fesa gishiri fiye da 1000h. Juriya mai zafi, fim ɗin inorganic, kuma fim ɗin bai ƙunshi danshi ba. Tsarin embrittlement-free hydrogen, acid-free da electrolytic shafi tsari, kauce wa hydrogen embrittlement kamar talakawa electroplating tsari.

Kwanciyar kwanciyar hankali na juzu'i yana da mahimmanci sosai don haɗa kayan haɗin mota. Tushen tutiya-aluminum flaky tushen ruwa shine mafita ga daidaituwar juzu'i. A kan tushen tushen zinc-aluminum, an yi amfani da ruwan inorganic na ruwa tare da aikin lubricating ---PLUS.

2. Fasahar suturar Electrophoretic

A cikin 'yan shekarun nan, wasu na'urori na wasu kamfanonin mota sun yi amfani da suturar electrophoretic maimakon passivation bayan lantarki. A cikin sauki kalmomi, ka'idar electrophoretic shafi ne "kishiyar jima'i janyo hankalin juna", wanda yake kamar maganadisu. Anode electrophoresis an rufe shi da kusoshi a kan anode kuma ana cajin fenti mara kyau; yayin da cathodic electrophoresis aka mai rufi tare da kusoshi a kan cathode, fenti yana da gaskiya caje. Kamar yadda muka sani, electrophoretic shafi ne sosai injiniyoyi, muhalli abokantaka, da kuma fenti fim yana da kyau kwarai lalata juriya. Maimaita da sake amfani da albarkatun ruwa don rage hayaki; ƙarfafa dawo da karafa masu nauyi don rage fitar da hayaki; rage VOC (magungunan kwayoyin halitta masu canzawa) watsi; rage amfani da makamashi (ruwa, wutar lantarki, man fetur, da dai sauransu), da kuma biyan bukatun kare muhalli don rage farashi da inganta inganci.

An yi amfani da shi ga sassa na auto da fasteners na shekaru da yawa. A electrophoretic shafi tsari ne in mun gwada da balagagge. Wani samfur ne da ke maye gurbin electroplating. PPGElect ropolyseal fastener na musamman electrophoretic shafi abu, EPll / SST 120 ~ 200h anode electrophoresis, EPll / SST 200 ~ 300h cathodic electrophoresis, EPlV / SST 500~1000h cathodic electrophoresis 1000h electrophoresis, electrophoresis 1500h, cathodic electrophoresis. da ZiNC Rich shafi tutiya-arziƙi Organic shafi (conductive).

Tare da ci gaban fasaha, ban da cathodic electrophoretic shafi tare da kyakkyawan juriya na lalata, an yi amfani da murfin anodic electrophoretic tare da wasu juriya na yanayi da murfin electrophoretic na cathodic tare da juriya na lalata kuma an yi amfani da su a zahiri akan layin samarwa. A halin yanzu, PPG's electrophoretic shafi jerin da aka amince da da yawa mota masana'antu kamfanoni, da kuma jerin bayani dalla-dalla da aka canza zuwa wani m misali, S424 aka canza zuwa S451, kamar Ford WSS-M21P41-A2, S451; Janar Motors GM6047 lambar G; Chrysler PS-7902 Mcthod C.

Abubuwan da ake amfani da su na suturar electrophoretic suna da kyau ga kare muhalli. Rufin Electrophoretic yana ɗaukar fenti na tushen ruwa, kuma passivation yana ɗaukar chromium trivalent; inganta juriya na lalata samfurin, kyakkyawan mannewa; babu ramin filogi, babu zaren dunƙulewa, kauri na fim iri ɗaya, ƙimar madaidaicin ƙarfi; na gargajiya electroplating + Passivation Tsari, gishiri fesa gwajin kai game da 144h. Bayan yin amfani da zinc phosphating + zinc-rich primer + cathodic electrophoretic shafi tsari, gishiri SPRAY gwajin iya isa fiye da 1000h, idan electroplating + cathodic electrophoretic shafi tsari da aka soma, da gishiri fesa gwajin iya isa fiye da 500h.

4, gamawa

A nan gaba, ci gaban na'urorin mota za su zama na musamman, tsarin kula da zafi zai zama mafi shahara a cikin halayen sabis, kuma fasaha mai fasaha, kore, da ƙananan nauyi za su taka muhimmiyar rawa. Haɓaka fasaha da kayan aiki shine ginshiƙi na haɓaka masana'antu na ci gaba, kuma har yanzu akwai ɗaki mai yawa don haɓakawa. Don takaita gibin da aka samu tare da ci gaban kasashen waje, aikin yana da matukar wahala, kuma aikin yana da nauyi da tsayi.

Shiga wannan labarin : Bincike kan sabon yanayin ci gaban fasaha na maganin zafi don masu ɗaurin mota

Bayanin Sake Buga: Idan babu umarni na musamman, duk labaran kan wannan rukunin yanar gizon na asali ne. Da fatan za a nuna tushen don sake bugawa:https://www.cncmachiningptj.com

PTJ® masana'anta ne na musamman wanda ke ba da cikakkiyar sandunan tagulla, sassan tagulla da kuma sassan jan karfe. Ayyukan masana'antu na yau da kullun sun haɗa da ɓata lokaci, ɗaukar hoto, smithing tagulla, waya edm ayyuka, etching, forming da lankwasawa, bacin rai, zafi ƙirƙira da dannawa, da huɗawa da naushi, da murɗa zare da dunƙulewa, da shewa. Multi spindle machining, extrusion da ƙirƙira ƙarfe da kuma stam. Aikace-aikace sun haɗa da sandunan bas, masu sarrafa lantarki, igiyoyi na coaxial, waveguides, abubuwan transistor, bututun microwave, bututun mold, da kuma foda metallurgy tankuna extrusion.

PTJ® masana'anta ne na musamman wanda ke ba da cikakkiyar sandunan tagulla, sassan tagulla da kuma sassan jan karfe. Ayyukan masana'antu na yau da kullun sun haɗa da ɓata lokaci, ɗaukar hoto, smithing tagulla, waya edm ayyuka, etching, forming da lankwasawa, bacin rai, zafi ƙirƙira da dannawa, da huɗawa da naushi, da murɗa zare da dunƙulewa, da shewa. Multi spindle machining, extrusion da ƙirƙira ƙarfe da kuma stam. Aikace-aikace sun haɗa da sandunan bas, masu sarrafa lantarki, igiyoyi na coaxial, waveguides, abubuwan transistor, bututun microwave, bututun mold, da kuma foda metallurgy tankuna extrusion.

Faɗa mana kaɗan game da kasafin kuɗin aikin ku da lokacin bayarwa da ake tsammani. Za mu ba da dabara tare da ku don samar da mafi kyawun ayyuka masu tsada don taimaka muku cimma burin ku, Maraba ku tuntuɓe mu kai tsaye ( sales@pintejin.com ).

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan