Ka'idojin da CNC lathes ya kamata su bi a cikin jerin juya sassa

Mai da hankali kan lathes CNC

Bayan zabar hanyar sarrafawa da rarraba tsarin, mataki na gaba shine tsara tsarin tsarin a hankali. Hanyoyin sarrafawa na sassa yawanci sun haɗa da hanyoyin yanke, hanyoyin maganin zafi da hanyoyin taimako. Daidaita tsari da tsari na yankan, maganin zafi da hanyoyin taimako, da kuma magance matsalar haɗin kai tsakanin hanyoyin, wanda zai iya inganta ingancin sarrafawa da samar da kayan aiki na sassa kuma rage farashin sarrafawa. . Don aiwatar da sassa akan lathe CNC, yakamata a raba hanyoyin bisa ga ka'idar maida hankali, kuma tsarin jujjuyawar sassa gabaɗaya yana bin ka'idodi masu zuwa.

1. CNC lathes ne m farko sa'an nan kuma mai ladabi a sassa aiki

Bi tsarin jujjuyawar juyi →Kammala juyi → gamawa juyi don haɓaka daidaiton mashin ɗin a hankali. M juya zai yanke mafi yawan machining izni a kan surface na workpiece a in mun gwada da ɗan gajeren lokaci, wanda ba kawai inganta karfe kau kudi, amma kuma gana da bukatun ga uniformity na karewa izni. Idan daidaitaccen gefen gefen da aka bari bayan jujjuyawar juyi ba zai iya cika buƙatun gamawa ba, ya kamata a shirya jujjuyawar juzu'i don sanya gefen ƙare ƙarami har ma. Lokacin da aka gama juyawa, kayan aikin yana motsawa tare da kwandon sashin a cikin wucewa ɗaya don tabbatar da daidaiton injin ɗin ɓangaren.

2. Lathe CNC yana kusa da farko sannan kuma ya fi nisa a cikin sarrafa sassa

Nisa da na kusa da aka ambata a nan sun dogara ne akan nisa tsakanin sashin sarrafawa da wurin canza kayan aiki. Yawancin lokaci a lokacin mashin injin, ana fara sarrafa sassan da ke kusa da wurin canjin kayan aiki, kuma ana sarrafa sassan da ke nesa da wurin canjin kayan aiki daga baya, don rage nisan motsi na kayan aiki, rage lokacin tafiye-tafiye marasa aiki, da kuma taimakawa kiyaye rigidity na blank ko rabin-ƙarami samfurin, da inganta Yanke yanayin.

3. CNC lathe ƙetare ciki da waje aiki sashi

Don sassan da ke da saman ciki (siffar ciki, rami) da kuma saman waje, lokacin da ake tsara tsarin sarrafawa, ya kamata a fara yin tagulla daga ciki da waje, sannan a gama na ciki da waje.

Lokacin sarrafa saman ciki da na waje, ana fara sarrafa mold da rami na ciki da farko, sannan kuma ana sarrafa saman. Dalilin shi ne cewa yana da wuya a sarrafa girman da siffar ciki na ciki, rashin ƙarfi na kayan aiki ba shi da kyau, ƙarfin kayan aiki (gefen) yana da sauƙin tasiri ta hanyar yanke zafi, kuma yana da wuya a cire. kwakwalwan kwamfuta a lokacin sarrafawa.

4. Ƙaddamar da kayan aiki na lathes na CNC a cikin sassan sarrafawa

Mahimmancin kayan aiki yana nufin ana amfani da kayan aiki guda ɗaya don sarrafa sassan da suka dace, sannan a yi amfani da wani kayan aiki don sarrafa sauran sassa, don rage bugun jini mara aiki da canjin kayan aiki.

5. CNC lathe daukan tushe surface na farko a sassa aiki

Ya kamata a fara fara sarrafa saman da aka yi amfani da shi azaman madaidaicin datum, saboda mafi daidaiton saman a matsayin datum ɗin sakawa, ƙaramin kuskuren matsawa. Alal misali, lokacin da machining shasha sassa, rami na tsakiya koyaushe ana sarrafa shi da farko, sa'an nan kuma ana sarrafa saman waje da ƙarshen fuska tare da rami na tsakiya azaman kyakkyawan tunani.

Ƙayyadaddun Hanyar Ciyarwa na CNC Lathe a cikin Sarrafa Sashe

Hanyar ciyarwa tana nufin hanyar da kayan aiki ke tafiya tun daga farawa har sai ya dawo zuwa wannan batu kuma ya ƙare shirin sarrafawa, ciki har da hanyar yanke kayan aiki da kuma rashin yankewa mara amfani kamar gabatarwar kayan aiki da yankewa.

1. CNC lathe yana gabatarwa da kuma yanke kayan aiki a cikin aikin sashi

Lokacin aiki akan lathe CNC, musamman ma lokacin da aka gama juyawa, ya zama dole a yi la'akari da yadda ake yankewa da yanke hanyar kayan aiki, da ƙoƙarin sanya tip ɗin kayan aikin jagora a ciki kuma yanke tare da tangent na kwakwan don gujewa. nakasar roba saboda canje-canje kwatsam a cikin yankan ƙarfi, haifar da matsaloli kamar tacewar ƙasa, maye gurbi ko alamun wuƙa da aka riƙe akan kwandon haɗin gwiwa mai santsi.

2. Lathe CNC yana ƙayyade mafi guntu hanyar tafiya mara kyau a cikin sarrafa sashi

Bugu da ƙari, dogara ga yawancin ƙwarewar aiki don ƙayyade mafi guntu hanyar tafiya ta iska, ya kamata kuma ya zama mai kyau a bincike, tare da wasu ƙididdiga masu sauƙi idan ya cancanta. A lokacin da ake hada tsarin sarrafa kwane-kwane da hannu, masu shirye-shirye (musamman mafari) wani lokaci suna aiwatar da “komawa zuwa sifili” (watau komawa wurin canjin kayan aiki) umarnin dawo da kayan aiki bayan kowane yanke zuwa wurin canza kayan aiki. Matsayi, sannan aiwatar da hanyoyin da suka biyo baya. Wannan zai kara nisa na hanyar wuka, ta yadda za a rage yawan aiki. Don haka, bai kamata a yi amfani da umarnin "komawa zuwa sifili" ba yayin aiwatar da janyewar kayan aikin ba tare da canza kayan aiki ba. Lokacin shirya hanyar wuka, nisa tsakanin ƙarshen ƙarshen wuka na baya da wurin farawa na wuka na gaba ya kamata ya zama ɗan gajeren lokaci don saduwa da mafi ƙarancin buƙatun hanyar wuƙa. Matsayin wurin canjin kayan aiki na lathe CNC yana dogara ne akan ka'idar cewa ba ta taɓa kayan aikin ba lokacin canza kayan aiki.

3. Lathe CNC yana ƙayyade mafi guntu hanyar ciyar da abinci a cikin sarrafa sassa

Gajerun hanyar ciyarwa na iya inganta ingantaccen samarwa da rage lalacewa na kayan aiki. Lokacin shirya hanyar yankan hanyar ciyarwa don roughing ko Semi-kammala, ya kamata a la'akari da tsayayyen sassan da aka sarrafa da kuma aiwatar da buƙatun aiki a lokaci guda, kuma kada ku rasa ganin ɗayan.

Shiga wannan labarin : Ka'idojin da CNC lathes ya kamata su bi a cikin jerin juya sassa

Bayanin Sake Buga: Idan babu umarni na musamman, duk labaran kan wannan rukunin yanar gizon na asali ne. Da fatan za a nuna tushen don sake bugawa:https://www.cncmachiningptj.com

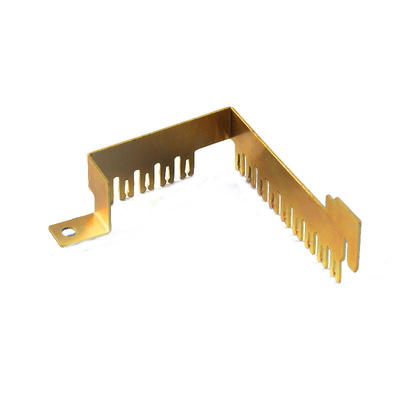

PTJ® masana'anta ne na musamman wanda ke ba da cikakkiyar sandunan tagulla, sassan tagulla da kuma sassan jan karfe. Ayyukan masana'antu na yau da kullun sun haɗa da ɓata lokaci, ɗaukar hoto, smithing tagulla, waya edm ayyuka, etching, forming da lankwasawa, bacin rai, zafi ƙirƙira da dannawa, da huɗawa da naushi, da murɗa zare da dunƙulewa, da shewa. Multi spindle machining, extrusion da ƙirƙira ƙarfe da kuma stam. Aikace-aikace sun haɗa da sandunan bas, masu sarrafa lantarki, igiyoyi na coaxial, waveguides, abubuwan transistor, bututun microwave, bututun mold, da kuma foda metallurgy tankuna extrusion.

PTJ® masana'anta ne na musamman wanda ke ba da cikakkiyar sandunan tagulla, sassan tagulla da kuma sassan jan karfe. Ayyukan masana'antu na yau da kullun sun haɗa da ɓata lokaci, ɗaukar hoto, smithing tagulla, waya edm ayyuka, etching, forming da lankwasawa, bacin rai, zafi ƙirƙira da dannawa, da huɗawa da naushi, da murɗa zare da dunƙulewa, da shewa. Multi spindle machining, extrusion da ƙirƙira ƙarfe da kuma stam. Aikace-aikace sun haɗa da sandunan bas, masu sarrafa lantarki, igiyoyi na coaxial, waveguides, abubuwan transistor, bututun microwave, bututun mold, da kuma foda metallurgy tankuna extrusion.

Faɗa mana kaɗan game da kasafin kuɗin aikin ku da lokacin bayarwa da ake tsammani. Za mu ba da dabara tare da ku don samar da mafi kyawun ayyuka masu tsada don taimaka muku cimma burin ku, Maraba ku tuntuɓe mu kai tsaye ( sales@pintejin.com ).

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan