Waɗanne buƙatun fasaha da ake buƙatar bi don mashin ɗin

Dangane da ƙwarewar sarrafa injina, ta hanyar bin waɗannan buƙatun ƙwarewa ne kawai samfuran da aka sarrafa za su iya zama mafi daidaito da ma'ana. Cikakkun buƙatun basira sune kamar haka

(1) Tsarin da aka sarrafa na sassan ba dole ba ne ya kasance yana da lahani irin su kasusuwa da tarkace da ke lalata bayyanar sassan.

(2) Cire ma'aunin oxide akan sassa.

(3) Ma'aikatan gwamnati a cikin nau'in da ba a yi musu allura ba za su cika bukatun GB1184-80, kuma kuskuren da aka amince da shi na ma'aunin tsayin da ba a yi ba shine ± 0.5mm.

(4) Yin bel na hukuma yana da kwatankwacin daidaitaccen kayan aiki na simintin babu komai.

(5) Shigar da mirgina ɗaukas, kuma an yarda a yi amfani da mai don dumama, kuma zafin mai kada ya wuce 100 ° C.

(6) Lokacin shigar da tsarin na'ura mai aiki da karfin ruwa, an yarda da yin amfani da kayan da aka rufe da masu rufewa, amma ya kamata a hana su shiga tsarin.

(7) Sassan da abubuwan da ke shigar da shigarwa suna buƙatar duba takaddun daidaito na sashin.

(8) Dole ne a tsaftace sassan kafin a sanyawa, kuma kada a sami burbushi, walƙiya, fatun oxide, tsatsa, guntu, tabon mai, masu launi, ƙura, da dai sauransu.

(9) Kafin shigarwa, bincika babban ma'auni na haɗin gwiwar sassa da sassa, musamman ma'aunin haɗin gwiwa da yawa da daidaito masu alaƙa.

(10) Yayin aikin shigarwa, sassan ba dole ba ne su yi karo, karo, lalacewa, ko tsatsa.

(11) Lokacin danne screws, bolts da goro, an hana yin tasiri ko amfani da na'urori masu juyawa da ba daidai ba. Bayan ƙarfafawa, kar a lalata ƙuƙumman dunƙule, ƙwaya da sukurori, da kawunan kusoshi.

(12) Ƙunƙarar ƙarar da ƙa'idar ke buƙata tana buƙatar zaɓaɓɓen magudanar wutar lantarki, sannan a ƙara matsawa kamar yadda ka'ida ta tanada.

(13) Bayan haɗawa, cire ragowar abin da ke gudana.

(14) Ba za a toshe ramukan da ke kusa da zoben waje na abin ɗagawa da wurin zama mai buɗewa da murfin ɗamara ba. Ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ramuka da ramin semicircular na wurin zama mai buɗewa da murfin ɗaukar hoto suna da kyakkyawar hulɗa. Lokacin dubawa ta hanyar canza launi, yana da ma'ana zuwa tsakiyar layin wurin zama. 120°, daidaitaccen lamba tare da murfin ɗaukar hoto a cikin kewayon 90° mai ma'ana zuwa layin tsakiya. Lokacin dubawa tare da ma'aunin abin ji a cikin kewayon da ke sama, ba za a saka ma'aunin jigon 0.03mm cikin 1/3 na faɗin zobe na waje ba.

(15) Bayan shigar da zobe na waje na bearing, ya kamata ya kasance a cikin haɗin kai tare da ƙarshen fuska na madaidaicin matsayi na ƙarshen matsayi.

(16) Bayan an shigar da abin birgima, ana iya mirgina shi a hankali kuma a tsaye da hannu.

(17) Fuskokin haɗin gwiwa na manya da ƙananan bushes suna cikin kusanci kuma ba za a iya ganin su tare da ma'auni na 0.05mm ba.

(18) Lokacin gyara daji mai ɗaukar hoto tare da fil ɗin sakawa, tabbatar da cewa buɗewa da rufe fuska da burodin ƙarewar fuskar soket da ƙarshen fuskar ramin abin da ya dace daidai suke da juna. Ba za a saki hinge da tallace-tallace ba bayan sokewa.

(19) An haramta amfani da ulu mai ɗauke da gawa idan suna launin rawaya. Ka'idar ita ce an haramta abin da ya faru na nucleation a cikin kusurwar taɓawa, kuma yankin nucleation a waje da kusurwar taɓawa ba zai wuce 10% na jimlar yankin da ba a taɓa taɓawa ba.

(20) Fuskar ƙarshen magana kaya (tsutsa kaya*** ya dace da kafada (ko fuskar ƙarshen hannun rigar matsayi), kuma ba za a iya gani tare da ma'auni na 0.05mm ba. Tabbatar da daidaitattun buƙatun na ƙarshen magana na kaya da axis.

(21) Tabbatar da bincika kusurwoyi masu kaifi, burrs da abubuwan waje waɗanda suka rage yayin sarrafa sassan kafin haɗuwa kuma cire su. Tabbatar cewa hatimin ba zai lalace ba lokacin da aka shigar da hatimin.

(22) Bayyanar simintin gyare-gyare ba ya yarda da lahani na ɓangaren sanyi, tsagewa, raguwar ramuka, lahani masu shiga da lalacewa mai tsanani.

(23) Ya kamata a tsaftace simintin gyare-gyare, ba tare da fashewa da walƙiya ba. Fitowar da aka nuna ta rashin sarrafawa yakamata su kasance santsi tare da bayyanar simintin gyare-gyare.

(24) Ya kamata a bayyana simintin simintin gyare-gyare da alamar bayyanar da ba a aiwatar da shi ba a fili, kuma matsayi da rubutun ya kamata su dace da buƙatun ƙirar.

(25) Ya kamata a tsaftace simintin gyare-gyare daga fita, ƙaya, da dai sauransu. Ragowar fitowar da ba a sarrafa su ba ya kamata ya zama santsi da goge don cika buƙatun ingancin bayyanar.

(26) Ya kamata a cire yashi mai gyare-gyare, yashi mai tushe da ainihin ƙashin da ke kan simintin.

(27) Simintin gyare-gyare suna da sassa masu karkata, kuma ma'aunin su na hukuma ya kamata a samar da su daidai gwargwado tare da abin da ya karkata.

(28) Gyara nau'in daidai da kuskure, karkatar da simintin shugaba, da dai sauransu, don cimma daidaiton sauyi da tabbatar da ingancin bayyanar.

(29) Filayen simintin gyare-gyaren ya zama santsi, kuma a cire kofa, burga, yashi, da dai sauransu.

(30) Simintin gyare-gyare ba sa yin alƙawarin lahani kamar shingen sanyi, tsagewa, ramuka, da sauransu waɗanda zasu lalata amfani.

(31) Kafin a fesa, bayyanar duk kayan ƙarfe da ake buƙatar fesa yana buƙatar cirewa daga tsatsa, sikelin oxide, maiko, ƙura, ƙasa, gishiri, da datti.

(32) Bayyanar simintin gyare-gyaren da ba a sarrafa shi ba yana buƙatar peening ko maganin abin nadi don biyan buƙatun matakin tsafta na Sa21/2.

Shiga wannan labarin : Waɗanne buƙatun fasaha da ake buƙatar bi don mashin ɗin

Bayanin Sake Buga: Idan babu umarni na musamman, duk labaran kan wannan rukunin yanar gizon na asali ne. Da fatan za a nuna tushen don sake bugawa:https://www.cncmachiningptj.com

PTJ® masana'anta ce ta al'ada wacce ke samarwa daidai kayan aiki da mikewa shashaing don aikace-aikacen ruwan ruwa da ruwan teku. Duk suna ƙera ƙarfe na al'ada da kuma ɗauka. Ƙarfin masana'anta sun haɗa da 5 Ƙaƙƙarfan Ƙaƙwalwar Axis Machining Copper Parts, kaya yankan, CNC milling, Lathing CNC, batsa, Farashin CNC, hobbing, honing, da ciki da waje forming. Sauran ayyukan sun haɗa da ƙarewa, ƙwanƙwasa, niƙa, ƙonawa, ƙare mai nuni, chamfering, daidaitawa da sarewa. An yanke maɓalli na radius bisa ga ƙayyadaddun bayanai. The shasha Ana sarrafa tsarin zuwa daidaitattun SAE J755.

PTJ® masana'anta ce ta al'ada wacce ke samarwa daidai kayan aiki da mikewa shashaing don aikace-aikacen ruwan ruwa da ruwan teku. Duk suna ƙera ƙarfe na al'ada da kuma ɗauka. Ƙarfin masana'anta sun haɗa da 5 Ƙaƙƙarfan Ƙaƙwalwar Axis Machining Copper Parts, kaya yankan, CNC milling, Lathing CNC, batsa, Farashin CNC, hobbing, honing, da ciki da waje forming. Sauran ayyukan sun haɗa da ƙarewa, ƙwanƙwasa, niƙa, ƙonawa, ƙare mai nuni, chamfering, daidaitawa da sarewa. An yanke maɓalli na radius bisa ga ƙayyadaddun bayanai. The shasha Ana sarrafa tsarin zuwa daidaitattun SAE J755.

Faɗa mana kaɗan game da kasafin kuɗin aikin ku da lokacin bayarwa da ake tsammani. Za mu ba da dabara tare da ku don samar da mafi kyawun ayyuka masu tsada don taimaka muku cimma burin ku, Maraba ku tuntuɓe mu kai tsaye ( sales@pintejin.com ).

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

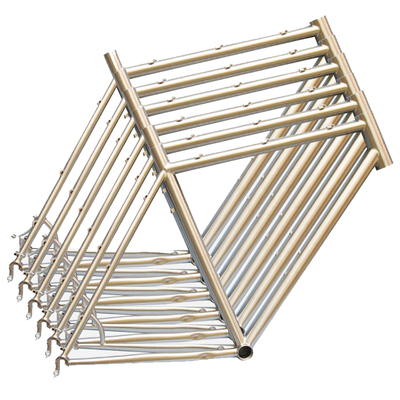

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan