Cikakken Misalai Na Fasahar Injin Injin Shaft

Cikakken Misalai Na Fasahar Injin Injin Shaft

| Ƙirƙirar ƙayyadaddun tsari a cikin shasha sassan suna da alaƙa kai tsaye da ingancin aikin aikin, yawan aiki da fa'idodin tattalin arziki. |

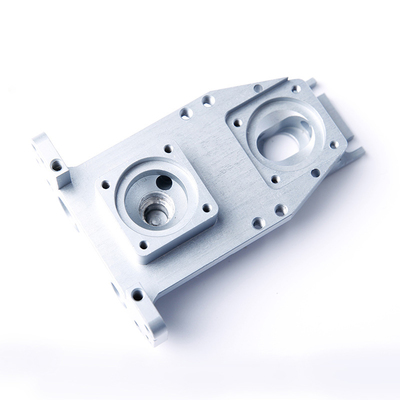

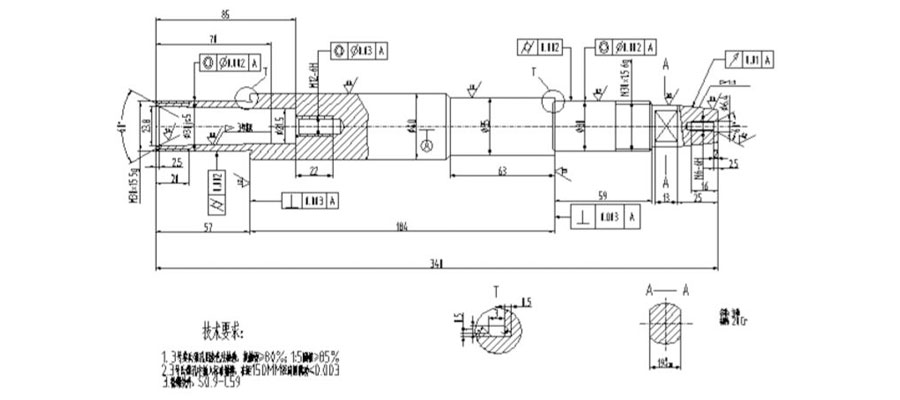

Dangane da abubuwan da ake buƙata na sama, mai zuwa misali ne. Carburizing sandal (hoton sama), guda 40 kowane tsari, abu 20Cr, sai dai na ciki da na waje zaren S0.9 ~ C59. Tsarin carburizing ya fi rikitarwa, kuma dole ne a zana zanen tsari don aikin roughing (hoto).

Ƙirƙirar ƙayyadaddun tsari a cikin sassan shaft yana da alaƙa kai tsaye da ingancin aikin aikin, yawan aiki da fa'idodin tattalin arziki.

Sashe na iya samun hanyoyin sarrafawa daban-daban, amma ɗaya kawai daga cikinsu ya fi dacewa. A cikin tsari na aiwatar da aiki ƙayyadaddun bayanai, dole ne a lura da waɗannan abubuwan.

- 1.A cikin bincike na tsari na zane-zane, Wajibi ne a fahimci buƙatun fasaha na sifofin tsarin, daidaitattun abubuwa, kayan aiki, maganin zafi, da dai sauransu, da kuma nazarin zane-zane na samfurin, zane-zane da kuma ka'idojin yarda.

- 2.Hanyar sarrafa sassa na carburizing shine gabaɗaya: yanke → ƙirƙira → normalizing → roughing → Semi-Finishing → Carburizing → Carburizing → Carburizing → Carbon Cire Carbon (ga bangaren da baya buƙatar inganta taurin) → quenching → threading, hakowa ko milling Groove → gamawa.

- 3.Zabin tunani mai kauri: Idan akwai filin da ba na injina ba, ya kamata a zaɓi wurin da ba na inji ba a matsayin maƙasudin mahimmanci. Don fitar da gatari waɗanda ke buƙatar injina a kan kowane saman, ana gyara mafi ƙarancin saman bisa ga izinin injin. Kuma zaɓi wuri mai santsi, bari ƙofar. Zaɓi ƙaƙƙarfan wuri mai dogaro a matsayin madaidaicin tunani, yayin da ƙaƙƙarfan tunani ba za a iya sake amfani da shi ba.

- 4.Kyakkyawan zaɓi na ma'auni: don saduwa da ƙa'idar daidaituwa ta asali, gwargwadon yiwuwa don zaɓar tushen ƙira ko ma'auni na taro azaman maƙasudin sakawa. Daidai da ka'idar benchmarking. Yi amfani da tunani iri ɗaya gwargwadon iyawa a yawancin ayyuka. Kamar yadda zai yiwu, nunin matsayi ya zo daidai da ma'aunin ma'auni. Zaɓin babban madaidaici, barga kuma abin dogara shine kyakkyawan ma'auni.

Tsarin Injin Spindle

1. Juyawa

Kayan aiki na sarrafawa: CA6140, Mohs No. 3 reamer, Mohs No. 3 toshe ma'auni 1: 5 ma'auni na zobe

Tsarin abun ciki: bisa ga zanen tsari yana juya duka zuwa girman

- (1) Ramin tsakiya φ2 yana hakowa a gefe ɗaya.

- (2) 1: 5 taper da Mohs 3 # gwajin launi na ciki, lamba surface> 60%.

- (3) Diamita na waje na kowane da'irar waje da za a yi ƙasa kada ta wuce 0.1 a cikin radial gudu na rami na tsakiya.

Lura: A ƙarshe duba

2.Rarfafa gwiwa

Abubuwan da ke aiki: maganin zafi S0.9-C59

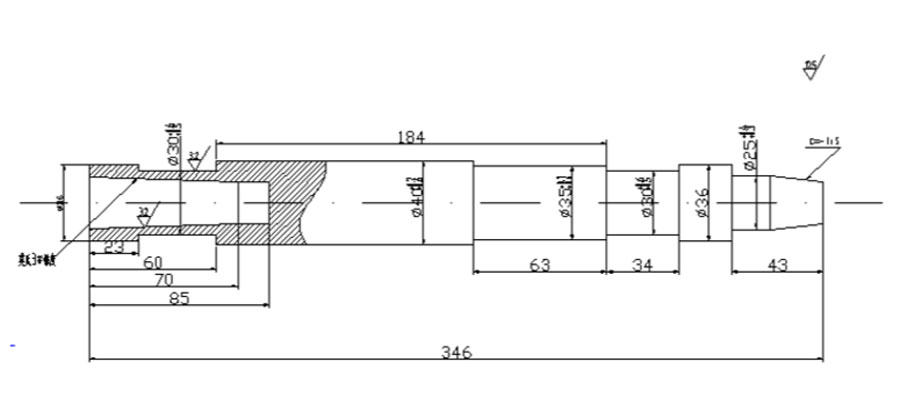

3. Juya

Tsarin abun ciki: deturningbonization. Ƙarshen ɗaya yana manne, ƙarshen ɗaya yana tsakiya

- (1) Ƙarshen fuska na juyawa yana tabbatar da cewa tsawon madaidaicin mataki na φ36 zuwa ƙarshen shaft shine 40.

- (2) rami na tsakiya φ5B nau'in

- (3) Juyawa

- (4) Ƙarshen fuskar juyawa, ɗaukar jimlar tsawon 340 zuwa girman, ci gaba da yin zurfi zuwa 85, 60 ° chamfer.

4. Juyawa

Kayan aiki: CA6140

Tsarin abun ciki: shirin guda ɗaya da saman ɗaya

- (1) Juya M30 × 1.5–6g zaren hagu babban diamita da ф30JS5 zuwa Φ30+6.0 +5 .0++

- (2) Juya φ25 zuwa φ25+0.2+0.1 tsayi 43

- (3) Juya φ35 zuwa φ353+0.4+0.3

- (4) Juya dabaran niƙa ta wuce gona da iri

5. Juyawa

Tsarin abun ciki: Juyawa, shirin bidiyo ɗaya da saman ɗaya

- (1) Babban diamita na zaren M30×1.5-6g da φ30JS5 zuwa φ30+0.6+0.5

- (2) Juya φ40 zuwa φ40+0.6+0.5

- (3) Juya niƙa dabaran overtravel Ramin

6.Milling

Abubuwan sarrafawa: Milling 19+0.28 jirage biyu zuwa girman

7.Hawan magani

Abubuwan da ake sarrafawa: maganin zafi HRC59

8.Bincike

Abun cikin tsari: Nika ramin tsakiyar ƙarshen biyu

9.Nika na waje

Kayan aiki: M1430A

Tsarin abun ciki: manyan tukwici biyu, (an katange ɗayan ƙarshen tare da mazugi)

- (1) m nika na φ40 waje da'irar, barin 0.1 zuwa 0.15 saura.

- (2) m nika φ30js waje da'irar zuwa φ30t+0.1+0.08 (wurare biyu) mataki nika

- (3) M nika 1:5 taper, barin nika izni

10.Cikin nika

Kayan aiki: M1432A

Tsarin abun ciki: yi amfani da madaidaicin mai siffa V (tsayawa a da'irar waje na ф30js5)

Momo's 3# mazugi na ciki (sake daidaita Mohs 3# mazugi) izinin ƙarewa 0.2 ~ 0.25

11.Hawan magani

Abubuwan da ke cikin tsari: ƙananan zafin jiki na maganin tsufa (baking), kawar da damuwa na ciki

12. Juyawa

Tsarin kayan aiki: Z-2027

Abubuwan da ke cikin tsari: manne a gefe ɗaya kuma a tsakiya a ƙarshen ɗaya

- (1) Hakowa φ10.5 rami, matsayi tare da hannun rigar jagora, zaren ba hari ba

- (2) Juyawa, hakowa φ5 famfo M6-6H zaren ciki

- (3) 60° tsakiyar rami na buɗewa

- (4) Drill hannun riga rawar soja rami hakowa ф10.5×25 (thread ba ya canja)

- (5) 60° rami na tsakiya, rashin ƙarfi na 0.8

13.Pliers

Tsarin abun ciki:

- (1) Saka tapping kayan aiki ɗauka hannun riga a cikin taper rami

- (2) Kai hari M12-6H zaren ciki zuwa girman

14.Bincike

Abubuwan da ke aiki: rami cibiyar bincike Ra0.8

15.Nika na waje

Abun cikin tsari: kayan aikin yana manne tsakanin saman biyun

- (1) Nika mai kyau φ40 da φ35φ25 da'irar waje zuwa girman

- (2) Milling M30×1.5 M30×1.5 hagu zaren babban diamita zuwa 30-0.2-0.3-

- (3) Semi-ƙarewa ф30js5 biyu zuwa ф30+0.04+0.03

- (4) Kyakkyawan niƙa 1: 5 taper zuwa girman, duba ta hanyar canza launi bisa ga taɓawar taɓawa ya fi 85%

16.Nika

Tsarin abun ciki: workpiece clamping biyu fi, nika thread

- (1) Mill M30 × 1.5–6g zaren hagu zuwa girman

- (2) Milling M30×1.5-6g zaren zuwa girman

17.Bincike

Abun aiki: Lapping tsakiyar rami Ra0.4

18.Nika na waje

Kayan aiki: M1432A

Tsarin abun ciki:

- (1) Nika mai kyau, kayan aiki mai matsewa tsakanin sama biyu

- (2) Niƙa mai kyau 2-φ30-0.003-0.007 zuwa girman, kula da juriya na geometric

19. Nika na ciki

Kayan aiki: MG1432A

Tsarin abun ciki:

An ɗora kayan aikin a cikin kayan aiki na V-dimbin yawa, kuma radius na ciki na Mohs 3 an daidaita shi akan 1-ф30 da'irar waje (zazzagewa, matsayi tare da 2-ф30js5 da'irar waje), kuma yanayin duban launi ya fi girma fiye da 80%. Yana buƙatar "1" da "2"

20. Janar

Tsari abun ciki: tsaftacewa da shafi anti-tsatsa mai, tsaye ajiya rataye a cikin workpiece

Wasu maki a cikin injinan shaft:

- 1.An yi amfani da ramukan tsakiya guda biyu a matsayin matsayi na matsayi, wanda ya dace da ka'idar da aka ambata na daidaituwa da daidaituwa.

- 2.The part farko yana amfani da waje da'irar a matsayin m tunani, karshen fuskar mota da kuma tsakiyar rami na rawar soja, sa'an nan kuma m da'irar m mota ne positioned tare da biyu cibiyar ramukan a matsayin matsayi reference, da kuma. Ana sarrafa ramin taper tare da da'irar waje na mota mai ƙaƙƙarfan a matsayin maƙasudin matsayi, wanda shine ka'idar tunani na juna. Mashin ɗin yana da datum ɗin sakawa wanda ya fi sau ɗaya daidai. No. 3 Mohs mazugi daidai buƙatun suna da girma sosai. Sabili da haka, ana buƙatar madaidaicin V-dimbin yawa don cimma buƙatun juriya na geometric tare da da'irar waje na 2-ф30js5 azaman madaidaicin matsayi. Lokacin da mazugi ya kasance a cikin motar, ƙarshen ɗaya yana manne da katsewa, kuma ƙarshen ɗaya yana tsakiya akan firam ɗin tsakiya, da'irar waje kuma ana amfani da ita azaman kyakkyawan tunani.

- 3.Lokacin da aka gama kammalawa da kammala da'irar waje, ana amfani da mazugi mai mazugi, kuma ana amfani da rami na tsakiya na mazugi a matsayin maƙasudin matsayi don kammala ma'auni na waje na shaft.

Don buƙatun toshe mazugi:

- 1.Cone plug yana da madaidaicin madaidaici, yana tabbatar da cewa madaidaicin mazugi na mazugi yana da matsayi mai girma tare da ramin tip.

- 2.Kada a maye gurbin mazugi na mazugi bayan shigarwa don rage kuskuren shigarwa wanda ya haifar da maimaita shigarwa.

- 3.Ya kamata a sanya diamita na waje na diamita na waje na mazugi na mazugi a kusa da ƙarshen shinge don sauƙaƙe cirewa da cire mazugi.

- 4.Babban shafting inji An carburized da taurare tare da 20Cr low-carbon gami karfe, da workpiece ba a bukatar da za a taurare (M30 × 1.5-6g hagu, M30 × 1.5-6g, M12-6H, M6-6H), barin 2.5-3mm carbon kau. Layer a saman. .

- 5.Bayan zaren ya ƙare, ba za a iya sarrafa shi a kan lathe ba. Idan zaren ya fara lanƙwasa sannan ya kashe, zaren zai lalace. Sabili da haka, zaren gabaɗaya baya ƙyale taurin, don haka dole ne a bar Layer na carbon a cikin diamita da tsayin yanki na zaren a cikin aikin. Don zaren ciki, 3 mm Layer decarburization ya kamata kuma a bar shi a bangon bango.

- 6.Don tabbatar da daidaiton rami na tsakiya, rami na tsakiya na workpiece kuma ba a yarda ya taurare ba. A saboda wannan dalili, jimlar tsawon blank shine 6 mm.

- 7.In domin tabbatar da nika madaidaicin na waje da'irar na workpiece, da tsari na nika tsakiyar rami dole ne a shirya bayan zafi magani, da kuma lafiya surface roughness ake bukata. Lokacin da m da'irar ne kasa, da roundness shafi workpiece ne yafi saboda coaxial na biyu saman ramukan da kuma roundness kuskure na saman rami.

- 8.Don kawar da damuwa na nika, an shirya tsarin tsufa na ƙananan zafin jiki (baking) bayan daɗaɗɗen niƙa.

- 9.To samun high-daidaici m da'irar, da nika ya kamata a raba zuwa m nika, Semi-kammala, da lafiya nika. An shirya niƙa mai kyau akan injin niƙa madaidaici.

Shiga wannan labarin : Cikakken Misalai Na Fasahar Injin Injin Shaft

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan