Aikace -aikacen Laser Farms A Manufacturing Farms

Aikace -aikacen Laser Farms A Manufacturing Farms

|

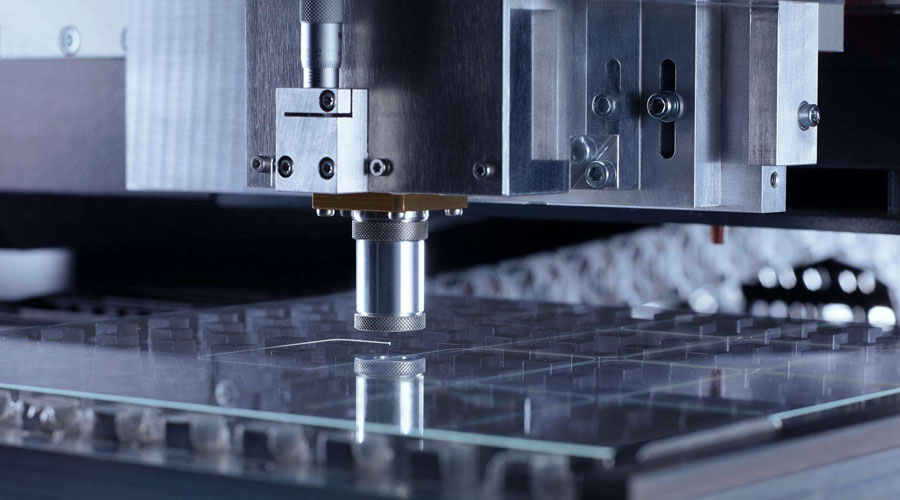

Jigon fasahar sarrafa Laser shine hulɗar da ke tsakanin katako na Laser da kayan. An kasu kashi Laser thermal sarrafa da photochemical dauki machining bisa daban-daban machining hanyoyin. Tsohuwar tana amfani da tasirin thermal da ke haifar da katako na Laser don aiwatar da ayyukan sarrafawa, kuma na ƙarshe yana amfani da yawa mai yawa. Photons masu ƙarfi suna fara halayen sinadarai don kammala aiki. Tare da haɓaka fasahar aikace-aikacen Laser, sarrafa laser ya zama babban fasahar aikace-aikacen tsarin laser. Ana amfani da shi sosai a fagen kera injuna kuma yana taka muhimmiyar rawa. |

1.Halayen fasahar injin laser

Yankan Laser fasaha ce ta zamani wacce ta haɗu da hankali da ci gaba, kuma ta haɗa ka'idodin laser, fasahar CAD da fasahar sarrafa lambobi. Ka'idar fasahar injin Laser ita ce ta taka rawa ta zahiri a saman kayan ta hanyar ƙarfin ƙarfin ƙarfin ƙarfin ƙarfin wutar lantarki, kuma yana haifar da jerin sauye-sauyen yanayi a saman kayan.

Fasahar injin Laser yana da fa'ida na daidaitattun daidaito kuma babu gurɓatacce, wanda babu kamarsa kuma ya zarce ta sauran fasahohin masana'anta. Bugu da ƙari, fasahar injin laser kuma tana haɗa nau'o'in nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan kayan lantarki, kayan aiki, da canja wurin zafi na injiniya, tare da babban matakin hankali.

Idan aka kwatanta da sauran machining fasahar a inji masana'antu, Laser machining sharar gida abu, yana da mafi girma yadda ya dace a manyan-sikelin samarwa, kuma shi ne mafi adaptable zuwa sarrafa kayan.

Ana iya amfani da shi don kera injiniyoyi daban-daban na kayan musamman na musamman, da kuma sauran injinan gargajiya Sabbin kayan da ba za a iya isa da su ta hanyar fasaha ba kuma ana sarrafa su ta amfani da fasahar injin Laser. Babban fasali na fasahar injin Laser a cikin masana'anta:

- (1) Babban iko, kayan za a iya narke ko vaporized a cikin ɗan gajeren lokaci bayan shafe zafin Laser, kuma ana iya canza kayan da sauri ko da ma'anar narkewar kayan yana da girma.

- (2) Shugaban Laser ba zai kasance cikin hulɗa kai tsaye tare da kayan aikin ba, don haka ba za a sami matsalolin lalacewa ba.

- (3) Ba wai kawai machining ayyuka a kan tsaye workpieces, amma kuma workpieces a cikin motsi, ko da kayan da aka shãfe haske a cikin wasu abubuwa.

- (4) A lokacin da Laser machining, da Laser katako ana sarrafa ta lantarki kwamfuta, wanda zai iya gane da daidai kayan aiki na injin, kuma matakin sarrafa kansa yana da girma.

- (5) Injin Laser na iya gane sarrafa injina, kuma ana iya amfani da robobi maimakon injina a wuraren da aikin ɗan adam ke da wahala.

2.Application na Laser machining a inji masana'antu

2.1 Gudanar da kayan aiki

Laser machining gabaɗaya yana amfani da maganin zafi da fasaha mai ƙarfi don sarrafa kayan. Wadannan fasahohin biyu na iya yin zafi da sauri a saman kayan kuma da sauri canza yanayin halittarsa lokacin da ya kusanci wurin narkewa, ta haka ne ya cimma manufar surface jiyya. Fasaha machining Laser kari ne na fasahar maganin zafi na gargajiya. Bayan laser machining, kayan yana da ƙarfin juriya ga gajiya da juriya na lalata.

An kuma tsawaita rayuwar sabis, kuma an inganta dukkan bangarorin aikin kayan. Aikace-aikace na Laser machining zuwa saman workpieces ya ƙwarai inganta jiki Properties na kayan, wanda yake da muhimmanci ga inganta kasuwa gasa kayayyakin.

Ana iya amfani da fasahar Laser ita kaɗai ko a haɗe tare da wasu fasaha don ƙirƙirar sabon yanayin sarrafa kayan. Haɗin fasahar Laser da fasaha na CAD ya buɗe sabon filin sarrafa kayan aikin injiniya. Fasahar CAD tana amfani da tsarin kwamfuta don sarrafa tsarin ƙira, kammala aikin ƙira na ɓangaren, sannan a yi amfani da fasahar Laser don aiwatarwa bisa tsarin ƙirar ƙira. Samfurin ɓangaren da aka kirkira tare da fasahar CAD yana da halaye na daidaito da kai tsaye, wanda zai iya sauƙaƙe wahalar kera sassa masu rikitarwa.

Idan matsaloli sun faru yayin tsarin ƙira, ana iya canza su a kowane lokaci don tabbatar da amincin samfurin. Masana'antar injina yana da tsauraran buƙatu akan sassan da kansu, kuma buƙatun don daidaito suna da tsauri. Mashin ɗin wasu rikitattun filaye masu lanƙwasa shima yana da wahala. Haɗuwa da amfani da fasahar CAD da fasahar Laser na iya magance wannan matsala cikin sauƙi, rage wahalar samarwa, da kuma rage zagayowar R & D don haɓaka haɓakar samar da samfur.

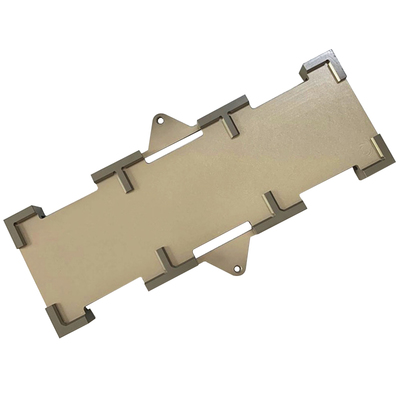

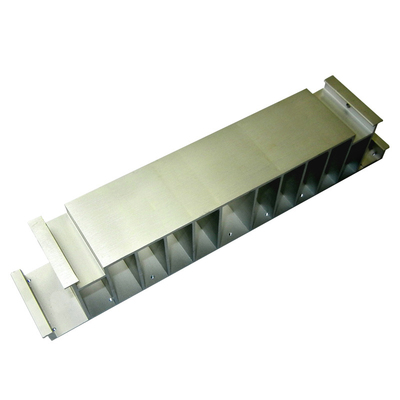

naushi da stam wani muhimmin bangare ne na injiniyoyin kayan aiki. Nau'in ramukan mashin ɗin gama gari sun haɗa da ramukan mai, ramukan ɗaure, ramukan sakawa, da dai sauransu. Ingantattun ramuka yana da tasiri mai mahimmanci akan aikin sashi. Sakamakon hakowa na injin laser ya fi na gargajiya hakowa, kuma bangon ramin ya fi santsi da zagaye, kamar yadda aka nuna a cikin Tebu 1. Matsakaicin zurfin rami da diamita na rami na tsawon lokaci a ƙarƙashin injin laser yana nunawa a cikin Hoto 1.

Ana iya ganin cewa yayin aikin hakowa na Laser, zurfin rami da diamita na rami ya karu sosai a matakin farko, kuma tare da tsawaita lokaci, haɓakar haɓakar dukkan su yana raguwa. Dalilin raguwar shi ne cewa makamashin da ke lalata hasken wutar lantarki ya ragu, sa'an nan kuma an juya tushen zafi na Laser zuwa cikin kayan. A wannan lokaci, da Laser tsarin

Shiga wannan labarin : Aikace -aikacen Laser Farms A Manufacturing Farms

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe Samar da samfura, cikakken kayan aiki, gudummawar fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe Samar da samfura, cikakken kayan aiki, gudummawar fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan