Matsayi Da Tsinkayar Fasahar Ingancin Laser

Matsayi Da Tsinkayar Fasahar Ingancin Laser

|

Kayan aikin Laser ya ƙunshi fa'ida mai yawa. Sintering, bugawa, sa alama, yankan, walda, gyare -gyaren farfajiya da ɗimbin kayan sinadarai duk sun ɗauki Laser a matsayin tushen makamashin da ba makawa. |

Za a iya mai da hankali kan katako na Laser zuwa ƙananan girman, yana sa ya dace da shi musamman daidai kayan aiki. Muna raba fasahar injin Laser na yanzu zuwa matakai uku bisa ga girman kayan da aka sarrafa da daidaiton bukatun injin:

- ① Laser machining fasahar ga manyan sikelin kayan, tare da kauri faranti (da yawa millimeters zuwa dubun millimeters) a matsayin babban abu, da machining daidaito shi ne gaba ɗaya a millimeter ko sub-millimita matakin;

- ② Daidaitaccen fasahar injin Laser, tare da faranti na sirara (0.1 zuwa 1.0mm) a matsayin babban abin injin, kuma daidaiton injin ɗin gabaɗaya yana cikin tsari na microns goma;

- ③ Laser microfabrication fasahar, don daban-daban fina-finai da kauri kasa da 100μm a matsayin babban machining abu, da machining daidaito ne kullum kasa 10 microns ko ma sub-micron matakin.

Dole ne a lura cewa a cikin masana'antar injin, daidaito yawanci yana nufin ƙananan ƙarancin ƙasa da ƙaramin juzu'i (ciki har da matsayi, siffar, girman, da sauransu). Sai dai kalmar "daidaitacce" a cikin wannan labarin tana nufin ƙaramin gibi a wurin da ake sarrafa shi, wanda ke nufin cewa iyakar girman da za a iya sarrafawa kaɗan ne. A sama iri uku Laser machining, da Laser machining fasaha na manyan sassa ta zama ƙara girma da kuma digiri na masana'antu ya kasance sosai high.Many literatures an sake nazari. Laser micro machining fasahar kamar Laser trimming, Laser daidai etching, Laser Direct rubuce-rubuce fasahar an kuma yi amfani da ko'ina a cikin masana'antu, kuma akwai da yawa alaka rahotanni. Wannan labarin zai mayar da hankali kan fasahar sarrafa mashin laser. Don dacewa, maƙasudin mashin ɗin don ingantattun mashin ɗin da aka ambata a ƙasa sun iyakance ga faranti na bakin ciki (0.1-1.0mm).

1 . Kwatanta tsakanin ma'anar mashin laser da hanyoyin sarrafa kayan gargajiya

Tare da ci gaban fasaha, nau'ikan fasahar injuna madaidaici suna karuwa sosai.

Laser machining machining yana da wadannan gagarumin fasali:

- ①A ikon yinsa, Laser daidai machining ne fadi, ciki har da kusan duk karfe da kuma wadanda ba karfe kayan. Yayin da mashin ɗin lantarki zai iya sarrafa kayan sarrafawa kawai, injin ɗin photochemical kawai ya dace da kayan lalata cikin sauƙi, kuma injinan plasma yana da wahala a sarrafa wasu manyan abubuwan da ke narkewa.

- ② Akwai ƴan abubuwa masu tasiri akan ingancin mashin ɗin laser, kuma daidaiton mashin ɗin yana da girma, kuma gabaɗaya ya fi sauran hanyoyin sarrafa kayan gargajiya gabaɗaya.

- ③ Daga ra'ayi na machining sake zagayowar, da kayan aiki electrode na EDM bukatar high daidaito, babban hasara, da kuma dogon machining sake zagayowar; da zane na cathode mold ga machining rami da profile na electrolytic machining ne babba, da kuma masana'antu sake zagayowar ne kuma dogon; Hanyoyin suna da rikitarwa; Laser madaidaicin mashin ɗin yana da sauƙi, slit nisa yana da sauƙi don daidaitawa da sarrafawa, saurin mashin ɗin yana da sauri, kuma tsarin mashin ɗin ya fi guntu fiye da sauran hanyoyin.

- ④ Laser daidai mashin ɗin nasa ne na mashin ɗin da ba na sadarwa ba, ba tare da ƙarfin injina ba. Idan aka kwatanta da EDM da plasma arc machining, yanayin zafi da ya shafa da nakasawa kadan ne, don haka yana iya sarrafa ƙananan sassa.

A taƙaice, fasahar injin laser na daidaici yana da fa'idodi da yawa akan hanyoyin injinan gargajiya, kuma hasashen aikace-aikacen sa yana da faɗi sosai.

2. Gabatarwa ga kayan aikin injin mashin laser da aka saba amfani da su

Lasers da aka fi amfani da su don yin mashin daidaici sun haɗa da: Laser CO2, Laser YAG, Laser vapor na jan karfe, Laser eximer Laser, da CO lasers, da sauransu. Don halayensu na laser, duba wallafe-wallafe don cikakkun bayanai.

Daga cikin su, ana amfani da laser CO2 mai ƙarfi da ƙarfin wutar lantarki na YAG a cikin manyan fasahar fasahar laser; Laser tururi na jan karfe da laser eximer an fi amfani da su a cikin fasahar micro-machining Laser; Ana amfani da laser na YAG matsakaita da ƙarancin ƙarfi gabaɗaya don yin ingantattun mashin ɗin.

3. Aikace-aikace na Laser machining machining da ci gaban kasar Sin da na duniya

3.1 Matsayi na duniya

3.1.1 Laser madaidaicin hakowa

Tare da ci gaban fasaha, hanyar bugun gargajiya ta kasa biyan bukatun a lokuta da yawa. Alal misali, ƙananan ramuka tare da diamita na dubun micrometers da yawa ana sarrafa su a kan tungsten carbide alloys mai wuya; ramuka mai zurfi tare da diamita na micrometers ɗari da yawa ana sarrafa su akan ja da ja da sapphire, da dai sauransu, waɗanda ba za a iya samun su ta hanyoyin injiniyoyi na al'ada ba. Matsakaicin ƙarfin wutar lantarki nan take na katako na Laser ya kai 108 W / cm2, wanda zai iya dumama kayan zuwa wurin narkewa ko wurin tafasa a cikin ɗan gajeren lokaci don cimma perforation akan abubuwan da ke sama. Idan aka kwatanta da wutar lantarki, lantarki, walƙiya na lantarki, da hakowa na inji, hakowa na Laser yana da inganci mai kyau, babban maimaita daidaito, haɓaka mai ƙarfi, babban inganci, ƙarancin farashi, da fa'idodin fasaha da tattalin arziƙi masu mahimmanci. Hakowa Laser daidaici na duniya ya kai matsayi mai girma. Wani kamfani na Swiss yana amfani da ingantattun lasers don huda ramuka a cikin injin turbin jirgin sama, wanda zai iya sarrafa microholes tare da diamita daga 20 μm zuwa 80 μm, kuma girman diamita zuwa zurfin zai iya kaiwa 1:80 (duba Hoto 1 (a)) . Har ila yau, katako na Laser yana iya sarrafa ramuka daban-daban na musamman kamar ramukan makafi (duba hoto na 1 (b)) da ramukan murabba'in kan kayan da ba su da ƙarfi kamar tukwane, waɗanda ba za a iya samun su ta hanyar injiniyoyi na yau da kullun ba.

3.1.2 Laser daidai yankan

Idan aka kwatanta da hanyar yankan gargajiya, daidaito yankan laser yana da fa'idodi da yawa. Misali, yana iya yin kunkuntar incisions, kusan babu ragowar yankan, ƙaramin yanki da zafin zafi ya shafa, ƙaramin yanke amo, kuma yana iya adana 15% zuwa 30% na kayan. Saboda Laser da wuya ya haifar da motsin injiniya da matsa lamba akan kayan da ake yankewa, ya dace da yankan kayan aiki mai wuyar gaske kamar gilashi, yumbu da semiconductor. Bugu da ƙari, wurin Laser yana da ƙananan kuma tsaga yana kunkuntar, don haka yana da musamman. dace da kananan sassa. Irin madaidaicin yanke. Wani kamfani na Swiss yana amfani da ingantattun lasers don yankan madaidaicin, kuma girman girman sa ya kai matsayi mai girma.

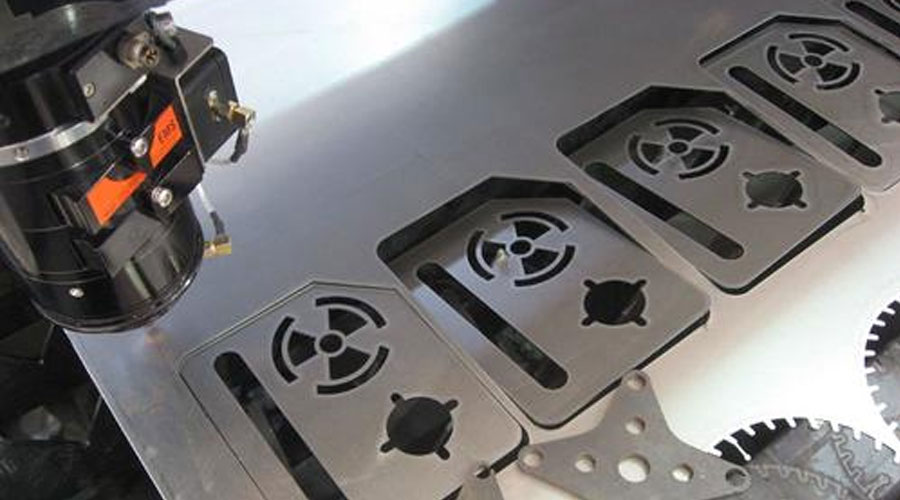

Ainihin aikace-aikace na Laser madaidaicin yankan shine yankan stencil na SMT a cikin allunan da'irori da aka buga (duba Hoto 2). Hanyar sarrafa samfurin SMT na gargajiya hanya ce ta etching sinadarai. Mummunan hasaransa shi ne cewa iyakar girman injin ɗin ba dole ba ne ya zama ƙasa da kauri na farantin, kuma hanyar etching sinadarai yana da tsari mai rikitarwa, dogon zagayowar mashin ɗin, kuma matsakaicin lalata yana lalata muhalli.

Yin amfani da mashin laser ba kawai zai iya shawo kan waɗannan gazawar ba, har ma ya sake yin samfurin da aka gama. Musamman ma, daidaiton machining da rata yana da mahimmanci fiye da na baya (duba Hoto 3). Ya ɗan yi ƙasa da na baya. Duk da haka, saboda yawan fasahar da ke tattare da dukkanin na'urorin da ake amfani da su don sarrafa injin Laser da kuma tsadar kayayyaki, kamfanoni kaɗan ne kawai a wasu ƙasashe kamar Amurka, Japan, da Jamus za su iya kera na'urar gabaɗaya.

3.1.3 Laser daidai walda

Waldawar Laser tana da kunkuntar yankin da zafi ya shafa da karamar kabu. Musamman ma, yana iya walda manyan abubuwa masu narkewa da karafa iri ɗaya ba tare da buƙatar ƙarin kayan ba. Amfani da ingantattun laser na YAG na duniya don waldawar kabu da walda ta tabo ya kai matsayi mai girma. Bugu da kari, wayoyin gubar na da'irar da aka buga suna walda su ta hanyar Laser, wanda baya buƙatar amfani da juzu'i, kuma yana iya rage girgizar zafin jiki ba tare da shafar mutuwar kewaye ba, ta yadda za a tabbatar da ingancin da'irar da aka haɗa ta mutu (duba hoto 4). .

3.2 Halin da ake ciki a kasar Sin

Bayan fiye da shekaru 20 na kokarin, a cikin sharuddan Laser machining fasahar da cikakken kayan aiki, ko da yake kasar Sin da aka yi amfani da yumbu Laser rubũta da Laser tabo waldi na micro-kananan karfe sassa, kabu waldi da iska-m waldi, da kuma alama. da dai sauransu.

Duk da haka, a cikin Laser ainihin machining fasahar, da microelectronic kewaye samfur daidai yankan da etching tsari tare da high fasaha abun ciki da kuma m aikace-aikace kasuwa, ta-ramuka, makafi ramukan da na musamman-dimbin ramukan, ramummuka na daban-daban bayani dalla-dalla da kuma girma dabam a kan yumbu zanen gado da kuma buga. Da'irar Allunan Laser mashin ingantattun injina da sauran abubuwan har yanzu suna cikin bincike da ci gaba, kuma babu wani samfurin masana'antu da ya bayyana.

Yawancin masu amfani a kasar Sin gabaɗaya suna amfani da samfuran da aka shigo da su ko injina na hukumar a Hongkong da sauran wurare.Tsarin farashi da tsayin daka sun yi tasiri sosai kan zagayowar haɓaka samfuran. A cikin 'yan shekarun nan, wasu 'yan manyan kamfanoni na kasa da kasa sun ga babbar kasuwa ta kasar Sin a cikin masana'antar injin laser. , Ya fara kafa rassa a kasar Sin. Koyaya, tsadar injina yana haɓaka farashin samfur kuma har yanzu yana sa kamfanoni da yawa su hana su.

4. Ci gaba Trend da Halaye na Laser Machining Machining Technology

Babban inganci, inganci, kwanciyar hankali, abin dogaro, da arha lasers sune abubuwan da ake buƙata don haɓakawa da aikace-aikacen mashin ɗin daidai. Ɗaya daga cikin ci gaba na ci gaba na ƙirar laser daidaitaccen mashin ɗin shine ƙaramin tsarin mashin ɗin. A cikin 'yan shekarun nan, lasers-diode-pumped lasers sun ci gaba da sauri. Yana da jerin fa'idodi irin su babban juzu'i mai inganci, kyakkyawan kwanciyar hankali na aiki, ingancin katako mai kyau, da ƙaramin girman. Yana yiwuwa ya zama babban Laser na gaba tsara na Laser machining machining.

Haɗuwa da tsarin mashin ɗin wani muhimmin al'amari ne a cikin haɓaka ƙirar ƙirar laser. Tsare-tsare da haɓaka fasahar injin mashin laser don abubuwa daban-daban; haɓaka abokantaka mai amfani, software mai kwazo na sarrafawa wanda ya dace da ƙirar laser daidaitaccen mashin ɗin, da ƙari da shi tare da bayanan tsari daidai; hada iko, tsari da Laser don cimma na gani na gani, Haɗuwa da na'ura, wutar lantarki da kayan aikin kayan aiki shine yanayin da ba zai yiwu ba a cikin ci gaba da ma'auni na laser.

Ko da yake kasar Sin tana da babban gibi tare da kasa da kasa dangane da fasahar sarrafa Laser da kayan aiki, idan muka ci gaba da inganta ingancin katako na Laser da daidaiton mashin din bisa na asali, hade da binciken fasahar sarrafa kayan, za mu mamaye madaidaicin laser. kasuwar machining kamar yadda zai yiwu. Kuma sannu a hankali shiga cikin filin Laser micro-machining, na iya inganta saurin ci gaban yankan laser fasaha, da kuma ƙarshe yin Laser daidai machining a cikin wani babban-sikelin masana'antu.

Shiga wannan labarin : Matsayi Da Tsinkayar Fasahar Ingancin Laser

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan