Babban Inganci Na Musamman na Cnc Don Madaidaicin Waya Machining Silinda Block da Shugaban Silinda

Matsakaicin Waya Machining Silinda Block da Shugaban Silinda

| Maganin daidaitawa na musamman na CNC na layin samar da sassauƙa shine tushen samun ingantacciyar mashin ɗin. Bari mu fara da mabuɗin tsarin ƙirar injin toshe iri-iri da kuma shugaban Silinda maras motsi da aka samar a kan layi ɗaya, da kuma tattauna mahimmin ƙira na tsare-tsare na ƙayyadaddun tsari don inganta inganci da ingancin layin samarwa. |

Sashe na 1 Ingantaccen Tsararren Tsare-tsare Don Roughing

A roughing tsari kammala m tsari sakawa tunani machining; an cire babban mashin ɗin, yayin da aka keɓance madaidaicin gefe don kammalawa don tabbatar da girman ƙarshe, daɗaɗawa, da ƙaƙƙarfan yanayin mashin ɗin. Ƙarƙashin yanayin tsari iri ɗaya na ma'auni na samfura masu yawa, mahimman abubuwan la'akari sune tsangwama na injin, yanke ingantaccen aiki da kwanciyar hankali na inji. Lokacin da ƙaƙƙarfan ma'auni na samfuran sun bambanta, wajibi ne don cimma daidaituwa ta hanyar ƙirar ƙirar ƙirar.

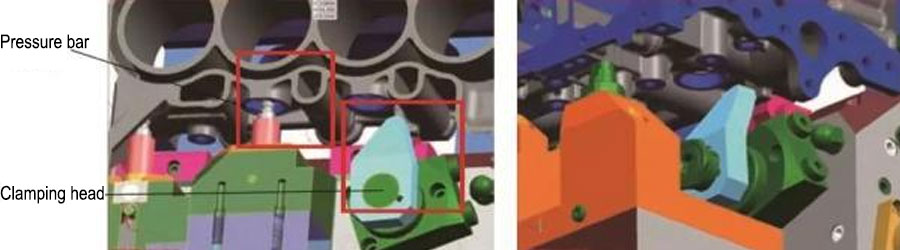

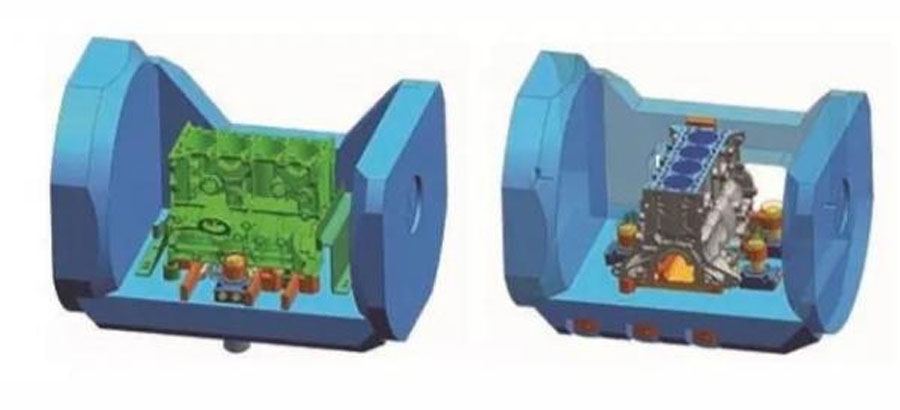

[1] Silinda toshe clamping makirci

Kamar yadda aka nuna a cikin Hoto na 1, ƙwaƙƙwaran mashin ɗin ya fi dacewa da kayan aikin injiniya kamar shingen silinda da saman ɗakin konewa. Bayan workpiece ne zaune, da matsa yafi tura sanda ta cikin mai Silinda don danna yashi kau rami na Silinda jiki don daidai danna part a cikin tunani shugabanci, amma sanda ne matsa saboda da simintin gefe, daftarin aiki kwana da kuma. yankan tasiri lodi. Karaya akai-akai yana shafar ingancin samarwa sosai.

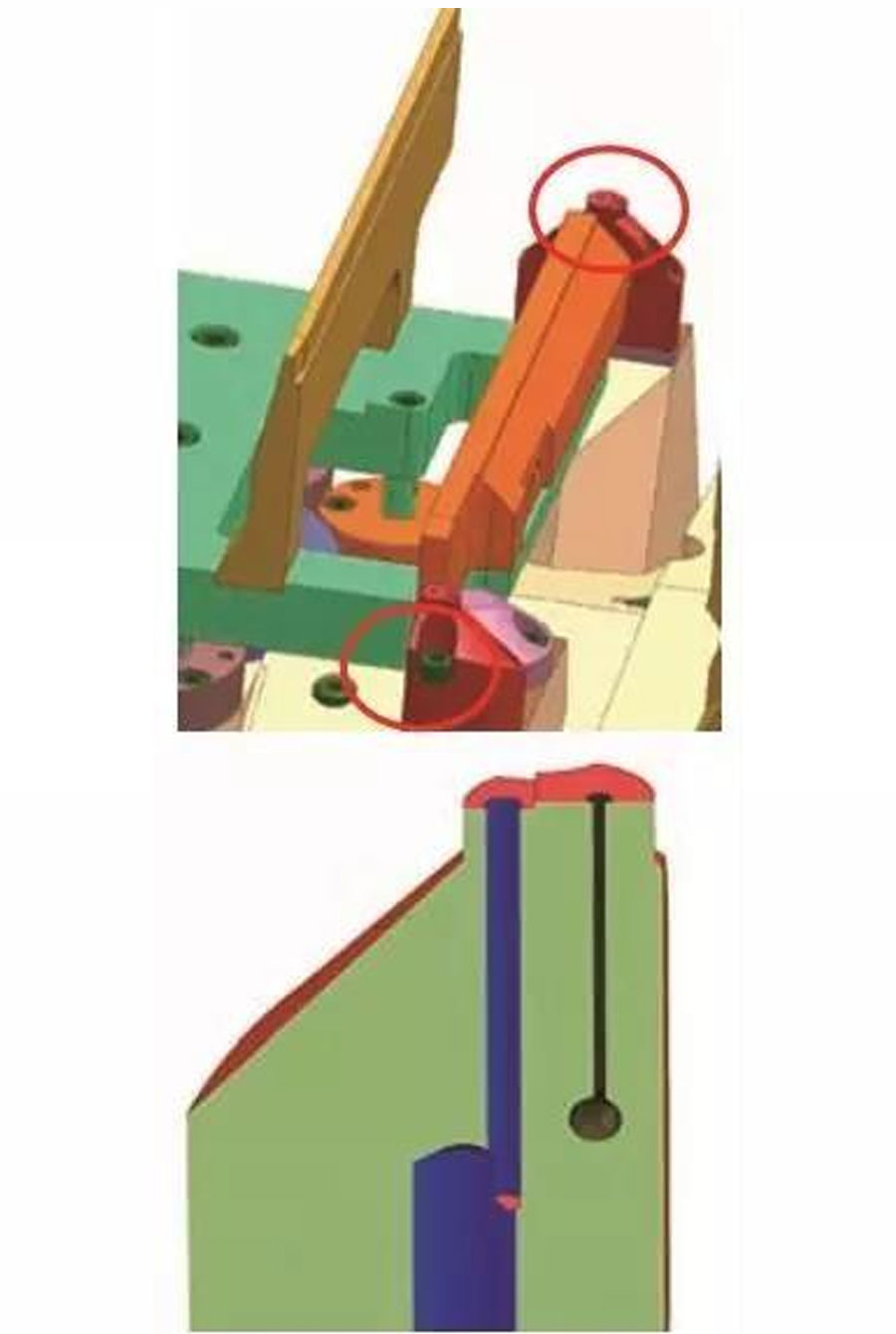

Duk da haka, matsin kai a wani wurin sakawa a wannan hanyar bai taɓa fuskantar matsalar karaya ba. Ta hanyar gyare-gyare a hankali na tsarin mai shiga, kamar yadda aka nuna a cikin Hoto na 2, an tsara wannan tsari na clamping don tsarin guda ɗaya, wanda zai magance matsalar fashewa saboda tasiri.

[2] Maganin daidaitawa biyu ya dace da samar da layin haɗin gwiwa

Matsakaicin madaidaicin matsayi na shugabannin silinda sun bambanta sosai, kuma ana ba da shawarar mafita guda uku don samar da samfuran daban-daban a cikin layi:

1) Ƙaddamarwa don gane halayen tsarin aiki;

2) Ƙara CNC;

3) Machining a kan guda CNC machining tsakiya.

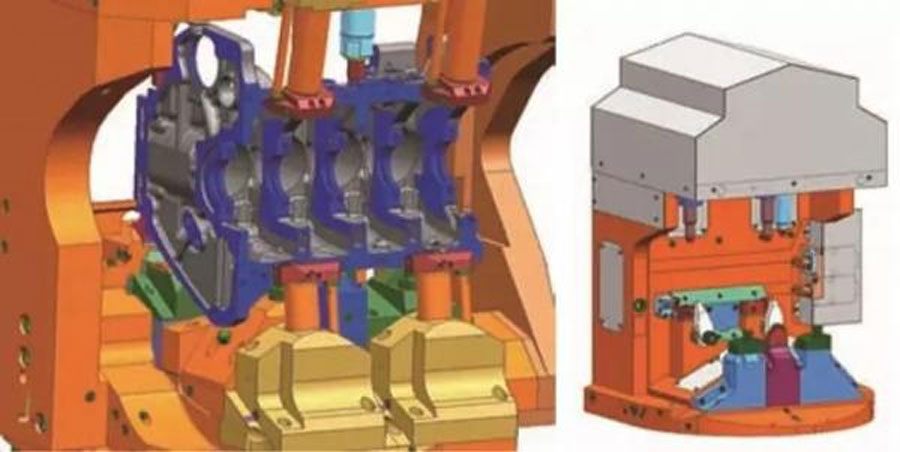

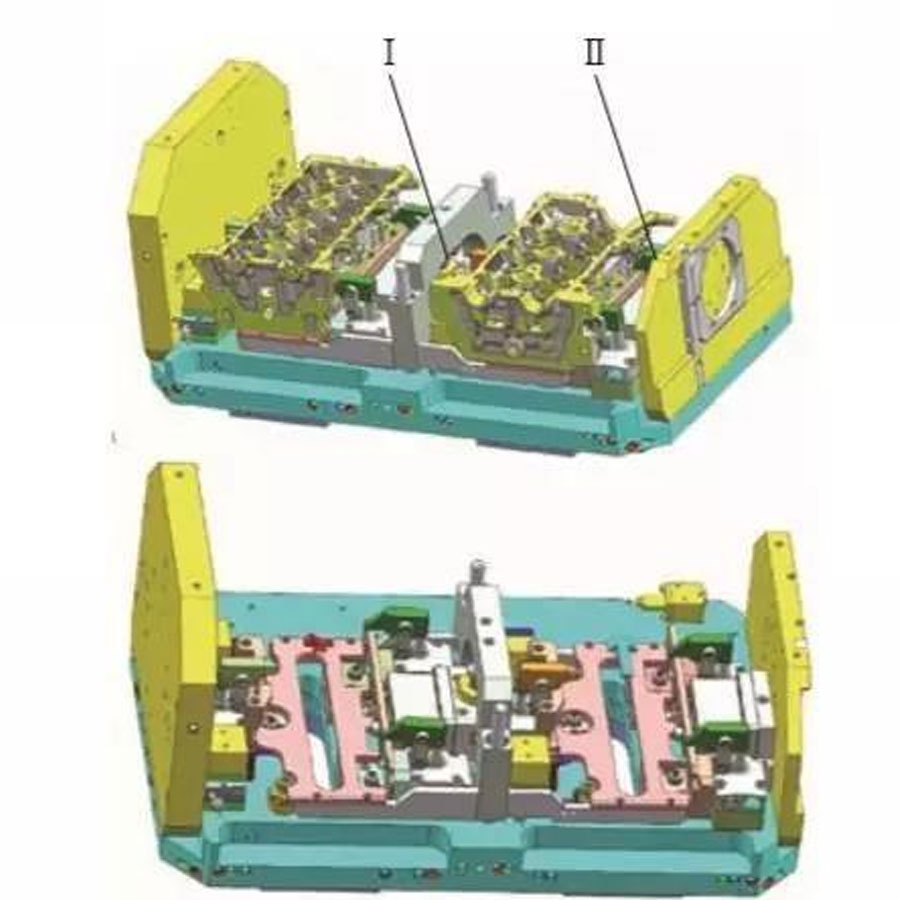

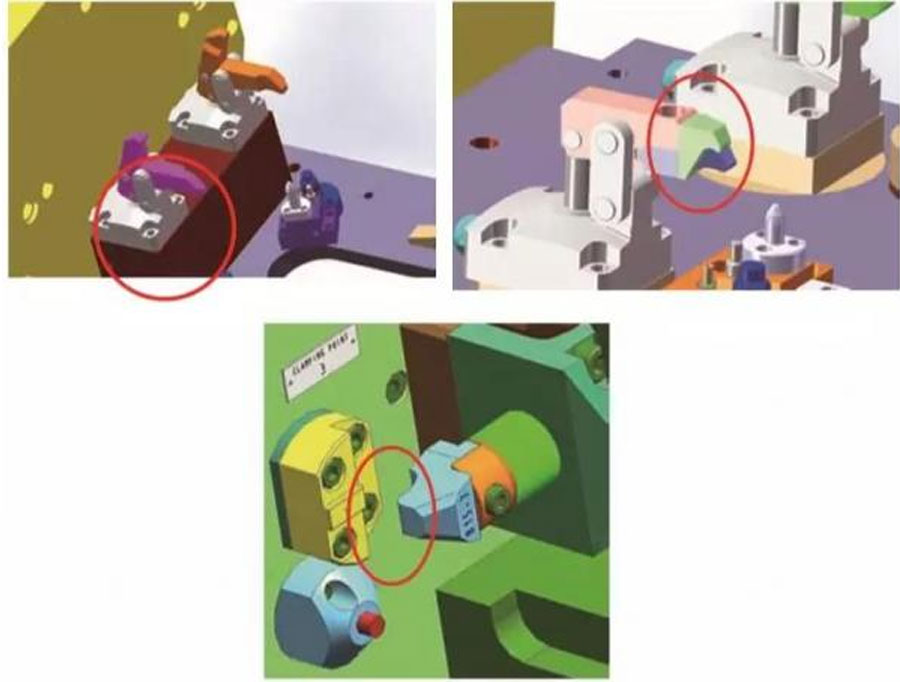

Ta hanyar canza na'urar sakawa ko saita tsarin daidaitawa biyu, an fi son tsarin daidaitawa biyu a cikin yanayin samar da taro bayan kimantawa. Kamar yadda aka nuna a cikin Hoto na 3, tsarin sanyawa na sassan silinda na manyan silinda na manya da ƙananan silinda ya bambanta da yawa: ƙirar ma'auni guda biyu Ⅰ an tsara shi don ƙananan kayan aikin silinda; Ⅱ shine babban matsayi na silinda machining, wanda yayi nasarar cimma nasarar sarrafa farashi da tabbacin inganci.

Sashe.2 Zane na Ƙarfafa Ƙarfafa bisa "Ganya ɗaya, Fita biyu"

Silinda block da Silinda shugaban ne na hali akwatin-type sassa machining. Dangane da machining, ana amfani da tsarin sakawa na "gefe ɗaya, fil biyu" don cimma nasarar jiragen sama 6 da tsarin rami.

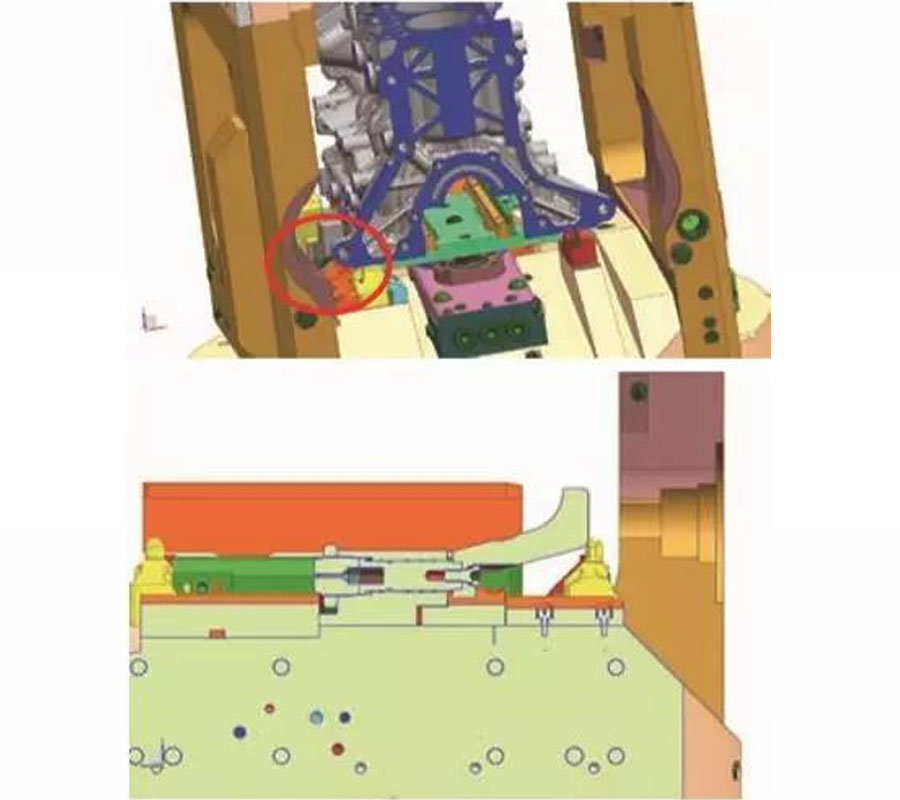

[1] Yin amfani da madaidaicin axis A / B

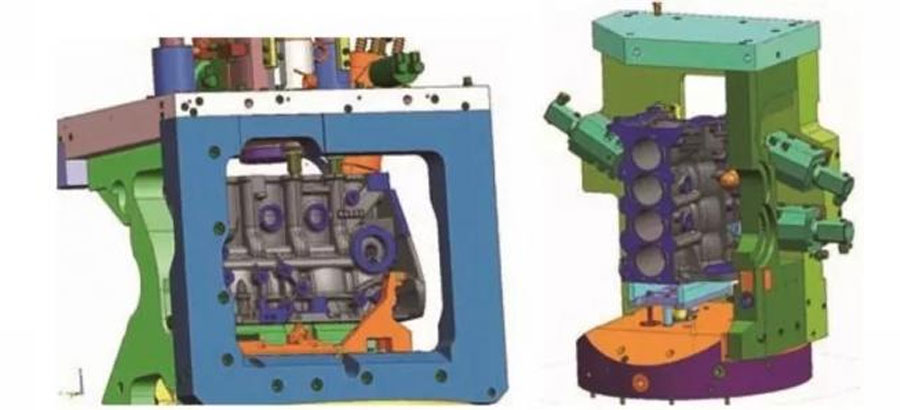

Dangane da hanyar watsawa ta B-axis, layin samar da toshe na asali na Silinda duk yana ɗaukar maganin daidaitawar B-axis. Kamar yadda aka nuna a hoto na 4, wasu fasalolin injina kamar crankshasha matsayi ramukan firikwensin da babban ɗauka Dole ne a juya saman haɗin gwiwar hula a tsaye don kammala aikin.

Bayan binciken masana'antu da aikace-aikacen aikace-aikacen A-axis na shugaban Silinda, nauyin mashin ɗin na ƙaramin simintin simintin silinda mai ƙaura da ke ƙasa 1.5L zai iya cika ka'idodin tsari ta hanyar injin A-axis. Kamar yadda aka nuna a cikin Hoto na 6, ta yin amfani da tsarin tandem na B-axis da A-axis na iya fahimtar dacewa da dacewa cewa saman ɓangaren ɓangaren yana fuskantar ƙasa, ba tare da buƙatar juya shi tsaye ba. Ba wai kawai yana adana lokacin aiki na ma'aikata ba, yana rage yawan aiki, amma kuma yana guje wa Yanke zubar ruwa yayin juyawa yana haifar da gurɓata muhalli ga yanayin aiki.

[2] Haɓaka ƙirar madaidaicin madaidaicin alloy na aluminum

Ana amfani da na'urar ƙwanƙwasa nau'in ƙarfi-nau'in ƙarfi don ƙira mashin ɗin shugabannin silinda na aluminium, wanda ba wai kawai yana guje wa lalacewar kawunan silinda ba, har ma ya cika buƙatun ƙarfin injin. Kamar yadda aka nuna a hoto na 6, yawancin tashoshi suna ɗaukar irin wannan ƙirar tsarin don saduwa da layin samarwa. Gwajin dorewa na dogon lokaci. Saboda babban bambance-bambance a cikin nisa mai matsewa, ba za a iya cimma matakan matsawa masu jituwa ba. Ta hanyar tsara tsarin chuck mai saurin canzawa, ana samun dacewa da sassa daban-daban.

[3] Daidaitaccen tsari na tsarin tsayawa a wurin

Dangane da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙira, an ƙera CNC don ɗaukar nauyi ta atomatik. Domin tabbatar da cewa ma'aikata suna turawa da cire sassa a wurin, ƙirar na'urar ƙaddamar da kayan aikin injin yana da mahimmanci musamman.

Sabili da haka, an nuna zane a cikin Hoto 7. Bayan an tura kayan aiki zuwa wurin, an haɗa hanyar gas na ciki na hanyar haɗin kai, kuma an canza matsa lamba a cikin tashar zuwa ƙimar da aka saita, don haka ana kula da sassan a wurin. . Ta hanyar rubuta wannan siginar zuwa ma'aunin kulle-kullen na'urar, na'urar ba ta sarrafa lokacin da sashin ba ya cikin wurin don hana sashin fadawa cikin kwandon injin.

[4] Sanya ƙirar tsarin gano iskar gas

Dangane da tsarin ƙira na "gefe ɗaya da fil biyu", kamar yadda aka nuna a FIG. 8, "gefe ɗaya" ya wuce maki 3 ko 4; “Fitai biyu” sune abubuwan daidaita fil ɗin zagaye da lu'u-lu'u.

[5] Zane-zanen tsarin anka

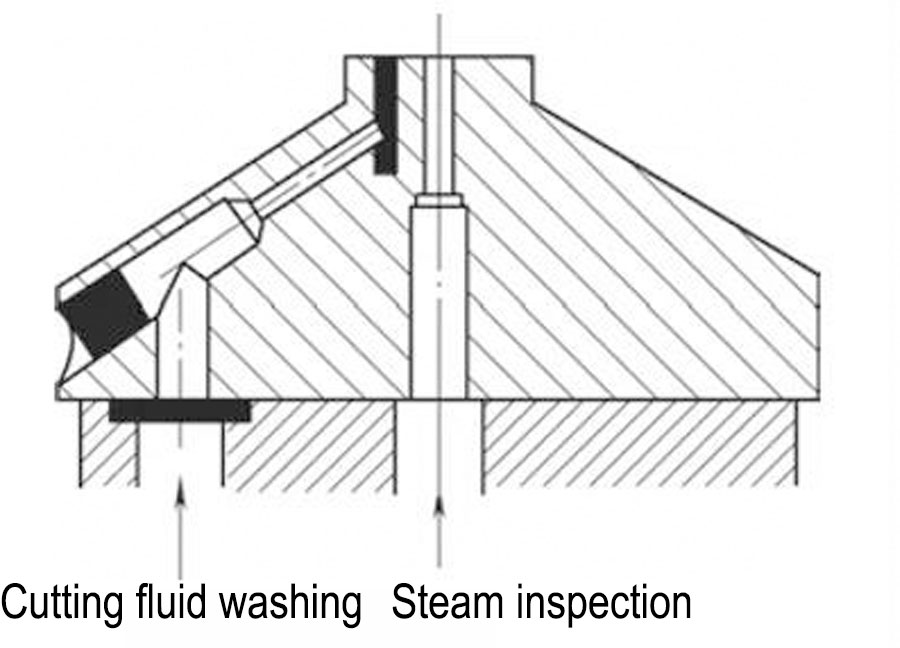

Kamar yadda aka nuna a cikin Hoto na 9, ana amfani da na'urorin saka idanu na iska da yankan na'urorin wanke ruwa a kowane wuri na madaidaicin: a yayin da ake sakawa, rashin daidaituwa na mashin din da aka yi da kayan aikin ƙarfe a kan shimfidar wuri yana hana wankewa; a lokacin mashin ɗin, duban iska yana sa ido kan duk ɓangaren don ƙaura.

Sashe na 3 Zane na kayan aiki don maɓalli masu mahimmanci

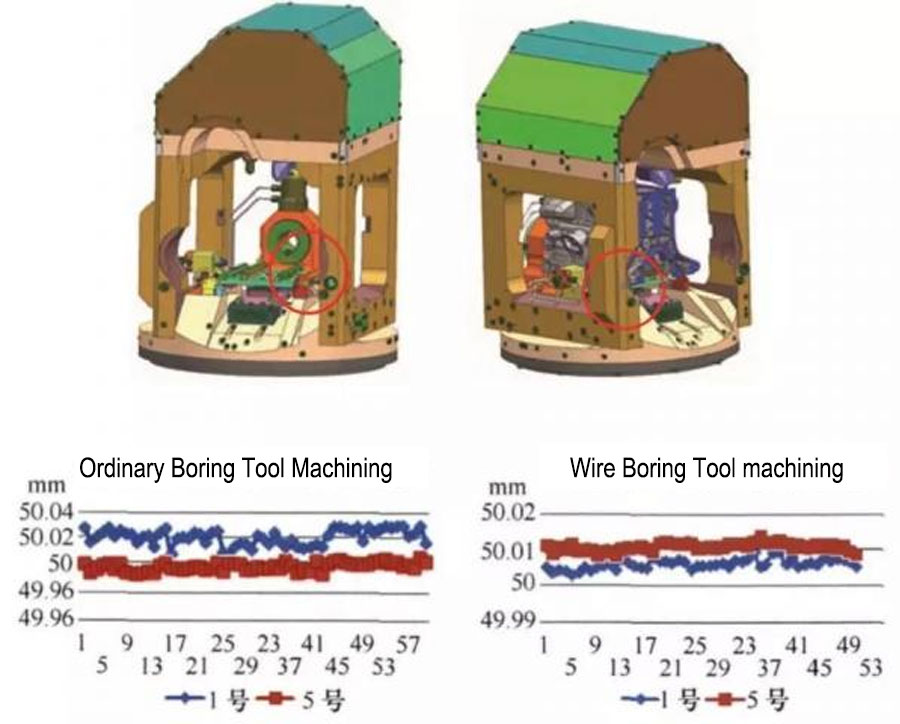

Machining ne duk CNC, yafi la'akari da samar da sassauci da kuma gabatar da sababbin kayayyakin a nan gaba. Koyaya, ikon dogon lokaci na mashin fasalin mashin ɗin ba zai iya biyan buƙatun tsari ba, kamar madaidaicin matsayi na ramukan crankshaft.

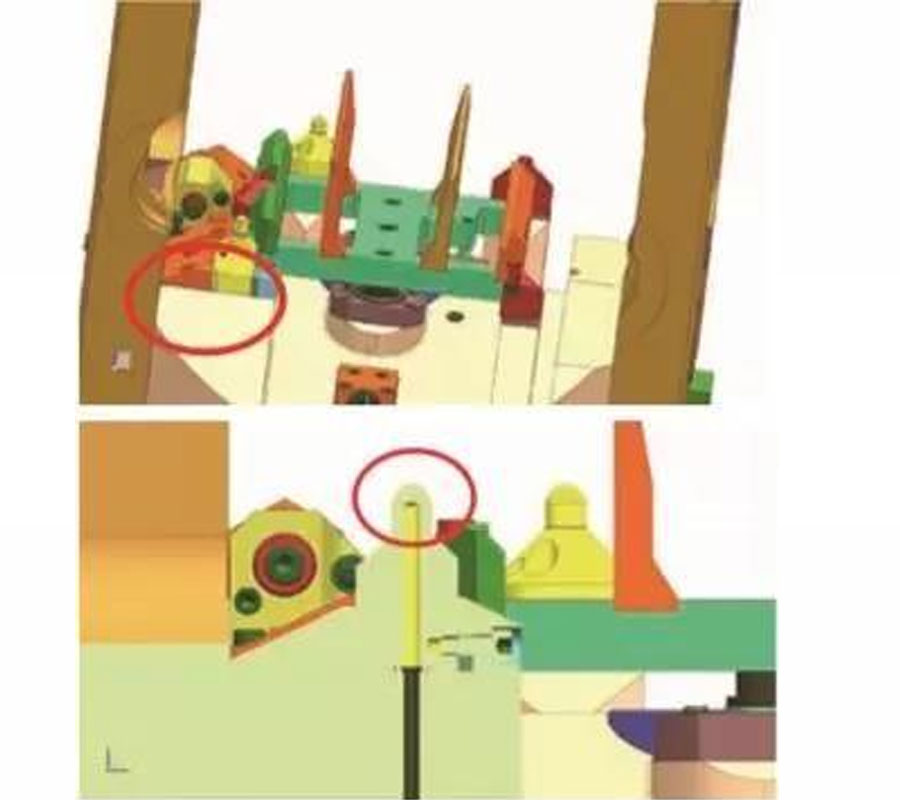

[1] Zane na musamman tasha

Ramin crankshaft na toshe Silinda ana sarrafa shi ta hanyar kayan aiki mai ban sha'awa na layi na musamman tare da halayen injin na musamman, wanda ba wai kawai la'akari da sassauci na CNC ba, har ma yana tabbatar da kwanciyar hankali na injin na musamman. Taurin yana haifar da bambancin matsayi. Duk da haka, kayan aiki mai ban sha'awa na layi yana da ƙayyadaddun buƙatu a tsakiyar abincin, kuma tsarin tsarin da aka danganta da haɗin gwiwar ramin fil yana da wani tasiri na rata.

Don kawar da rata, kamar yadda aka nuna a cikin Hoto 10, an ƙara silinda mai turawa zuwa gefen ɓangaren. Bayan aikin aikin yana zaune, ana tura sashin zuwa gefe ta sandar turawa don kawar da tasirin rata mai yuwuwa don tabbatar da tsakiya. Ta amfani da na musamman-manufa waya m abun yanka bayani a kan CNC, tsakiyar bambanci tsakanin gaba da raya iyakar crankshaft rami da aka samu nasarar inganta daga 0.025mm zuwa cikin 0.01mm.

[2] Na'urar auna kan layi don kayan aikin maɓalli na tashar

Ana amfani da binciken kan layi don sarrafa mahimman fasalulluka na sassa kamar akwatin, kuma suna shiga tsakani a cikin tsari don haɓaka ƙarfin injina. Irin su Silinda toshe tura surface, Silinda block Silinda shugaban konewa dakin surface da sauran muhimman siffofin machining ganewa, domin tabbatar da machining size ikon, ta hanyar bincike auna cimma kayan aiki lalacewa diyya. Don guje wa tasirin ɗanyen ƙarfe na bincike, aski na aluminum, da jujjuyawar jiki, da dai sauransu, ana shigar da ma'aunin ma'auni mai ma'auni akan kayan aiki, kuma ana daidaita tsarin ma'auni akai-akai tare da sanya idanu don tabbatar da daidaiton injin. girman.

An sami nasarar haɓaka kayan aiki na musamman don sassan akwatin kuma an yi amfani da su a cikin layin samar da jikin silinda da kawunan silinda. Sai dai ana buƙatar canza wasu abubuwan haɗin gwiwa da jagorar da hannu, na'urorin sakawa ba sa buƙatar canza na'urorin, wanda zai iya fahimtar samar da manyan nau'ikan samfuran 3 na cikin layi. A gauraye amfani da A / B gatura dogara ne a gefe daya da biyu fil yadda ya kamata gajarta samar da taimako lokaci da kuma inganta aikace-aikace na ergonomics, musamman aikace-aikace na musamman inji ra'ayi ga zane na CNC kayan aiki, wanda yadda ya kamata inganta na dogon lokaci. machining damar key fasali.

Shiga wannan labarin : Babban Inganci Na Musamman na Cnc Don Madaidaicin Waya Machining Silinda Block da Shugaban Silinda

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ Kwararru ne Cnc Machining Shop yana da 12 shekaru gwaninta a kan al'ada maras misali sassa.ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ Kwararru ne Cnc Machining Shop yana da 12 shekaru gwaninta a kan al'ada maras misali sassa.ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan