Gano Hanyar Coaxiality Na Mashinan Sassan PEEK

Gabatarwa da wakilcin alamar coaxial

|

1. Coaxial shine lokacin fasaha na injiniya wanda ke wakiltar juriya na matsayi a cikin siffar da matsayi na sassa. Abubuwan da suka dace sune axis da axis, rami da rami, da axis da rami. Ana buƙatar madaidaiciyar layi ɗaya ko daidaitawa, wanda ke nufin sarrafawa Nawa ainihin axis ya karkata daga axis! 2. An bayyana alamarta a matsayin da'irar da'ira biyu: ◎ |

Mahimman sakamako mara kyau na manyan kurakurai coaxial

Kuskuren Coaxial shine rashin daidaituwa na tsakiyar da'irar da aka nuna a cikin sashin giciye. Idan an shigar da sassan da manyan kurakuran coaxial da amfani da su, ƙila ba za a haɗa su yayin haɗuwa ba. Na'urar da aka haɗa na iya haifar da girgiza, girgiza, hayaniya na lokaci-lokaci, tsotsa mara ƙarfi, lalata sassan injin, kuma yana iya haifar da mummunar lalacewa. Jerin cututtuka na inji kamar haɗari na aminci, don haka kula da haɗin gwiwar abubuwan haɗin gwiwa koyaushe ya kasance muhimmin abu na ingantattun kayan aikin PTJ Shop Plastics Machining.

Nau'in sassa don auna coaxial

Dole ne a yi ma'aunin ma'auni ta sassa masu juyawa, kamar shashas, kayas, busar da kais da sauran sassa.Gwajin gwaji

Coaxiality yana da wuyar aunawa. Kayan aikin da muke amfani da su sun haɗa da masu ɗaukar hoto, masu daidaitawa guda uku, mitoci masu karkata, ƙarfe masu siffar V, alamun bugun kira, da na musamman. maras motsi.

Hanyoyin aunawa

Gano coaxial abu ne na gwaji wanda muke yawan yi a cikin aikin aunawa. Mai zuwa shine taƙaitaccen gabatarwa ga hanyar gano coaxial na shaft da kayan aikin da kamfani ke samarwa.

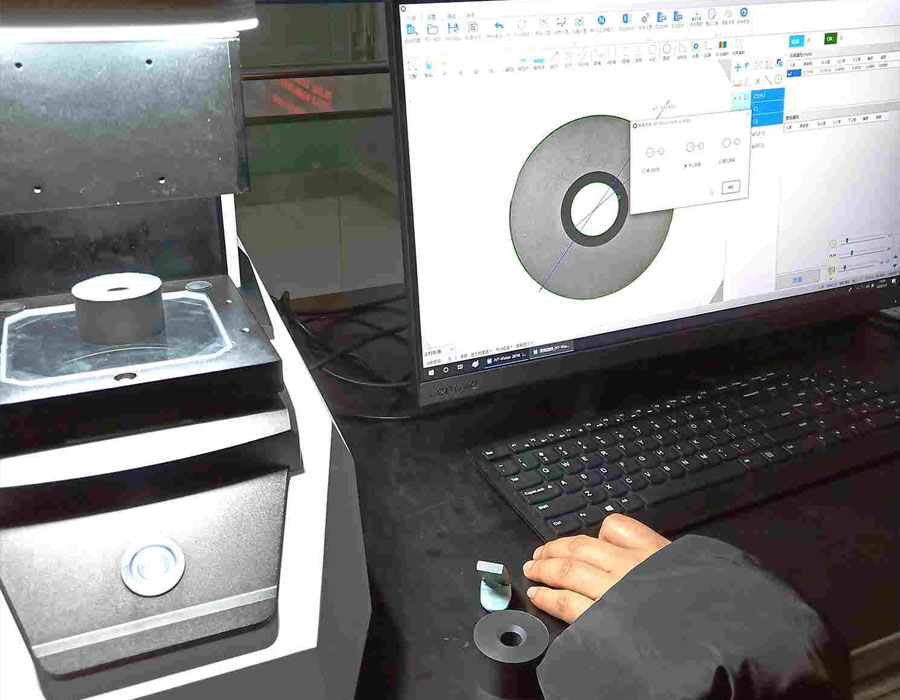

1.Hanya don auna coaxial tare da hoto

- 1. Kunna kwamfutar kuma sanya sashin da aka gwada akan benci na aiki

- 2. Bude flash button a cikin kwamfuta da kuma shigo da shirin

- 3. Danna da'irar waje da rami na ciki na abin da aka auna tare da linzamin kwamfuta, sannan danna maɓallin ma'auni

- 4. Karanta bayanan coaxial, rikodin shi, kuma cika rahoton gwajin!

2. Hanyar auna coaxiality tare da daidaitawa guda uku (CMM)

- 1. Gano zane da farko kuma nemo ma'auni.

- 2. Gyara da leko machining sashi da za a auna a kan uku daidaita dandamali da kuma gyara shi da ƙarfi.

- 3. Kunna coordinates guda uku, daidaita kai, kunna kwamfutar, nemo software na ma'aunin da ya dace, buɗe software, sa'an nan kuma shirin.

- 4. Fara auna samfuran, kafa tsarin daidaitawa, da auna da'irar waje.

- 5. Ƙayyade ma'auni, kimanta silinda da aka auna, sannan za ku iya ganin coaxiality.

- 6. Fitar da rahoton gwajin.

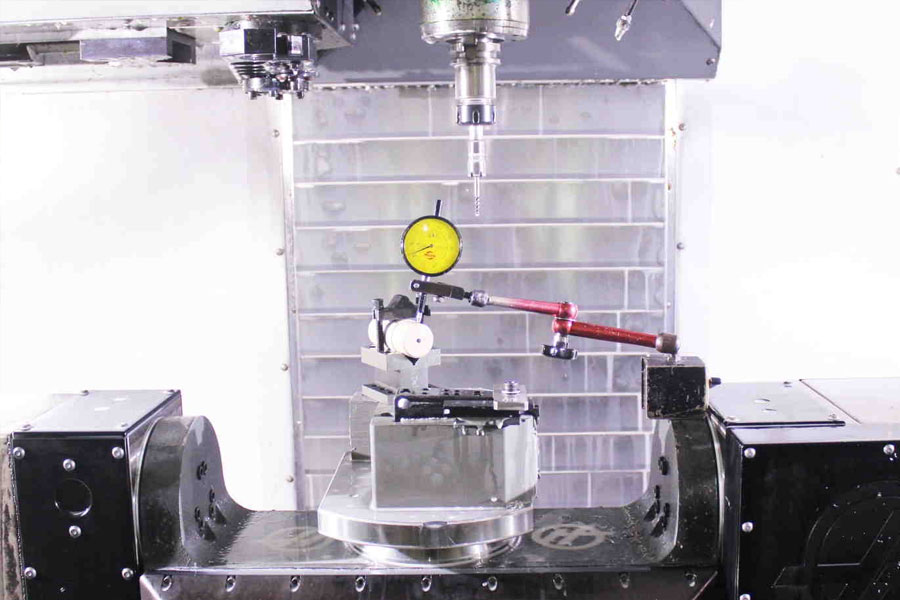

3.Hanyar auna coaxiality tare da yaw

- 1. A wanke gunkin gwajin da ruwan dumi kuma a shafe shi da bushe bushe.

- 2. Daidaita nisa tsakanin tukwici biyu na yaw, wanda shine kusan 8 mm ya fi guntu sashin shaft don aunawa. Daidaita tsakiyar rami na ƙarshen gwajin gwajin tare da kafaffen titin yaw. Jawo kayan aikin da hannun hagu ka damfara karkatar da hannun damanka. Hannun tip mai motsi a ɗayan ƙarshen pendulum yana sa titin motsi ya koma baya. Hannun hagu da dama suna aiki da kyau sosai, kuma suna tura tip ɗin motsi cikin rami na tsakiya akan ɗayan ƙarshen aikin!

- 3. A jujjuya abin da za a gwada da hannu, sannan a juya shi cikin sauki, amma kada tazarar ta yi yawa. Tabbatar cewa abu ya matse. In ba haka ba zai haifar da sakamakon gwaji mara kyau. Idan kana buƙatar daidaita elasticity, da fatan za a koma zuwa Mataki na 2 a sama.

- 4.Shigar da alamar bugun kira, tushe, da tsayawa, da daidaita alamar bugun kira don binciken ya kasance cikin hulɗa tare da ma'aunin waje na aikin aiki, kuma akwai matsawa na 0.5--1 da'irar.

- 5. Sannu a hankali kuma daidai gwargwado juya aikin aikin da hannu har tsawon mako guda, kuma lura da jujjuyawar alamar bugun kira, ɗauki bambanci tsakanin karatun Mmax da karatun Mimin a matsayin kuskuren coaxiality na sashin, sannan rikodin bayanai.

- 6. Matsar da alamar bugun kira, zaɓi da'irar waje, juya ɓangaren da za a auna, kuma auna matsayi huɗu daban-daban bisa ga hanyar da aka bayyana a sama. Ɗauki ƙimar MAX na bambanci tsakanin karatun Mmax da karatun Mimin azaman ɓangaren kuskuren Coaxial.

- 7. Kammala rahoton gwajin kuma tsara kayan aikin gwaji.

4. Hanyar gano coaxial tare da baƙin ƙarfe V-dimbin yawa

- 1. A wanke gunkin gwajin da ruwan dumi kuma a shafe shi da bushe bushe.

- 2. Shirya tubalan V-dimbin yawa guda biyu tare da tsayi iri ɗaya da yanki guda ɗaya. Sanya tubalan da aka shirya masu nau'in V a kan dutsen marmara ko a kan tebur ɗin inji mai faɗi sosai.

- 3. Saka ma'auni na workpiece da za a gwada a cikin V-dimbin yawa tsagi na kayan aiki

- 4. Shigar da ma'aunin bugun kira, tushen tebur, da tsayawar mita, daidaita ma'aunin bugun kira don binciken ya kasance cikin hulɗa tare da ma'aunin waje na aikin aiki, kuma akwai matsawa na 0.5 --- 1 da'irar.

- 5. Latsa ƙasa da hannuwanku kuma a hankali da iri ɗaya jujjuya aikin na tsawon sati ɗaya, kuma lura da jujjuyawar alamar bugun kira, ɗauki bambanci tsakanin karatun Mmax da karatun Mimin azaman kuskuren coaxiality na sashin kuma rikodin bayanai.

- 6. Sa'an nan kuma matsar tushe na tebur, zaɓi da'irar waje, juya sashin da za a auna, auna matsayi daban-daban guda hudu bisa ga hanyar da ke sama, kuma ɗauki darajar MAX a cikin bambanci tsakanin karatun Mmax da karatun Mimin. Kuskuren axiality

- 7. Kammala rahoton gwajin kuma tsara kayan aikin gwaji.

5. Hanyar gano coaxial na kayan aiki na musamman

Hanyar lissafin bayanai da cika rahoton

- 1. Da farko ƙididdige ƙimar kuskuren coaxial akan sashin auna guda ɗaya, wato, Δ = Mmax-Mmin.

- 2. Ɗauki ƙimar MAX na ƙimar kuskuren coaxial da aka auna akan kowane sashe azaman kuskuren coaxial na ɓangaren.

- 3. Kammala ma'auni bisa ga matakan da ke sama kuma cika bayanan da suka dace da sakamakon ma'auni na DUT a cikin rahoton gwajin da ya dace, kuma yi amfani da wannan a matsayin ma'ana don sanin ko kuskuren coaxial na ɓangaren yana karɓa.

Shiga wannan labarin : Gano Hanyar Coaxiality Na Mashinan Sassan PEEK

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan