Nazarin Machining Manyan Titanium Turbine Blades Profile Tsari

Nazarin Machining Manyan Titanium Turbo Tsari Tsari

|

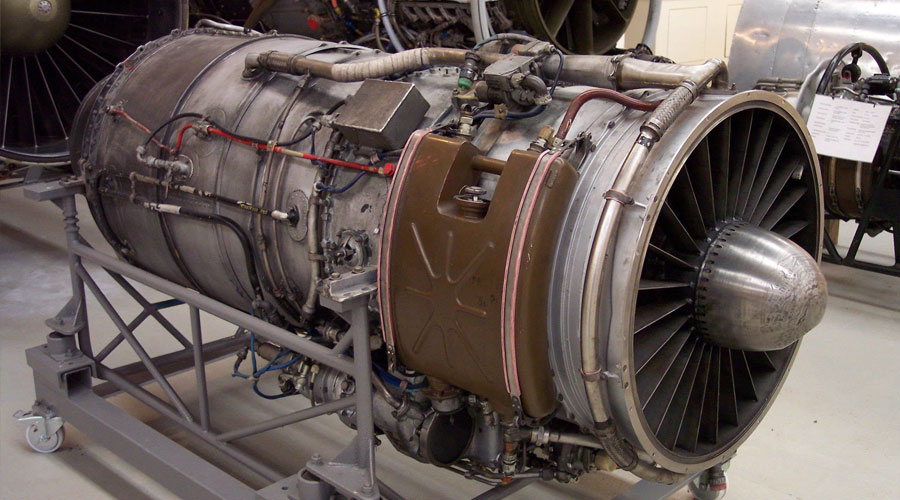

Wuraren fan na babban ingin turbofan na kewayawa sun kai fiye da 500MM dangane da tsayi da girma. Wannan babban sikelin tsarin yana sa ƙarfin centrifugal da damuwa na girgiza ya zama babba yayin aikin su, don haka ya zama babban injin fan turbo Mahimmanci sassa. |

A halin yanzu, yawancin injunan turbofan har yanzu suna amfani da mafi girma Titanium gami da damping ruwan fanfo. ƙunƙuntaccen tsari mai tsayi na wannan bayanin martabar ruwa yana sa rashin ƙarfi nasa a cikin nau'i na siriri mai bango a cikin kwandon baya ya fi fice. Rashin ƙaƙƙarfan ƙaƙƙarfan tsari da babban yanki na bayanin martaba, yanayin kayan aiki yana da wuyar sarrafawa, yana da mummunar tasiri akan al'ada. aiwatar da aiki, wanda ke nunawa a hankali a cikin daidaitattun girman kwane-kwane da daidaiton matsayi na bayanin martaba Yana da wuya a ba da garanti, ingancin gogewar hannu yana da ƙasa, ƙarfin aiki yana da girma, kuma nau'in ganye yana da haɗari ga ƙonewa da ablation.

Kasancewar matsalolin da ke sama sun zama ƙulli ga samar da ruwa. Tare da haɓakawa da aikace-aikacen haɗin gwiwar multi-axis Cibiyar CNC fasaha da bincike kan fasahar injina na wannan bayanin martaba, an warware wahalhalun da ke tattare da injina a hankali, kuma ingancin injina da ingancin aikin ya kai matsayin da ya dace.

Babban hanyar fasaha ta CNC machining na manyan titanium gami fan bayanin martaba

Don yin mashin ɗin babban bayanin martabar alloy fan na titanium, la'akari da duk abubuwan da ke cikin al'adar al'ada, tasirin sa yana da abubuwa masu zuwa.1. Tasirin kayan aiki

- ▶ Gilashin titanium yana da ƙananan nau'i na roba, wanda yake da sauƙi don haifar da nakasar ƙwanƙwasa na mashin ruwa; lalacewa na gefen gefe a lokacin machining yana da wuyar ƙara ƙarfin yankewa.

- ▶ Rashin ƙarancin zafin jiki, bushewar niƙa da aka goge da hannu yana da sauƙi don haifar da nakasar damuwa, konewa, da zubar da ciki.

2. Tasirin tsarin ruwa

- ▶ Gabaɗayan machining na bayanan martaba yana da girma, kuma daidaitattun lalacewa yayin aiwatar da kayan aikin yana da tasiri sosai.

- ▶ Saboda rashin jin daɗi a cikin mu'amala, goge goge na hannu yana da wahala sosai, kuma yana da wahala a tabbatar da daidaiton mashin ɗin.

3. Tasirin yanayin ulu

Saboda tasirin kayan aiki da ƙayyadaddun bayanai, yana da wahala a sami ingantacciyar rarraba ta gefe, wanda ke haifar da yanke jujjuyawar ƙarfi wanda ya haifar da rashin daidaituwar cire gefen bayanin martaba da nakasar damuwa.4. Tasirin ayyukan kayan aikin injin

- ▶ Tsarin lanƙwasa na bayanin martabar ruwa, jagorar yanke kayan aiki, ainihin madaidaicin kusurwa da sigogin yanke sun bambanta, yana haifar da canje-canje a cikin ƙarfin yankewa.

- ▶ Yanayin sanyi mara kyau, rashin isasshen sanyaya kuma babu sanyaya yana haifar da nakasar damuwa ta thermal.

Yin niyya a cikin mawuyacin dalilai na machining na ruwa surface na manyan titanium gami magoya, dangane da m machining abũbuwan amfãni daga Multi-axis linkage CNC machining fasahar, babban machining hanya ƙaddara shi ne:

na'ura mai sarrafa igiyar ruwa da datum sakawa na taimako → bayanin martabar ruwa CNC rough milling Machining → Stress Relief Annealing → Matsayin Gyara Mahimmanci → Sarrafa Lambobi CNC Blade Milling → Ƙarshen Bayanan Bayanan.

The overall tsari ra'ayin kafa ta sama tsari hanya ne: da surface CNC m milling tsari cire mafi yawan gefe, da kuma gama milling tsari yana da manufa gefe rarraba; bayanin martabar ruwa na CNC daidaitaccen tsarin niƙa yana tabbatar da lissafi na bayanin martaba Kuma daidaiton matsayi ya dace da ainihin buƙatun daidaito na ruwa; Ƙarshen bayanin martaba na ruwa yana tabbatar da cewa ingancin shimfidar wuri na bayanin martaba ya dace da bukatun.

Babban maki na CNC milling na manyan titanium gami fan ruwa profile

Dangane da buƙatun fasaha gabaɗaya na bayanin martabar ruwa, niƙa na bayanin martabar ruwa dole ne a tabbatar da cewa daidaiton matsayi na geometrical na bayanin martaba ya dace da buƙatun ƙira kuma yana da ƙayyadaddun ingancin saman. A lokaci guda kuma, haɓaka ingantaccen aiki a cikin injina kuma shine abin da ake mayar da hankali kan aikin milling profile Aiki ɗaya.

Bisa ga fahimtar machining halaye na babban titanium gami fan ruwa profile, shi wajibi ne don cikakken la'akari da tasiri na abubuwa da yawa kamar kayan aiki, kayan aiki, machining matsayi da sauransu. Don niƙa manyan ƙwanƙolin ƙarfe na titanium gami da fan, ya zama dole don zaɓar cibiyar injin axis biyar. Zaɓin babban cibiyar injuna haɗin kai mai axis biyar yana da la'akari da ingantattun ingantattun kayan aikin da ingantattun ingantattun injina.

Don injinan bayanan martaba tare da manyan canje-canje a cikin curvature, aikin kusurwar mashinan sandar kayan aikin na'ura na iya dacewa da buƙatun daidaitaccen ƙarfin yanke daidai da canji a cikin curvature na bayanan martaba. Tsarin kwantar da hankali na kayan aikin injin yana rage yawan zafin jiki kuma yana guje wa lalacewa da sauri. , Don mashin ɗin bayanan martaba na iya samun daidaiton mashin ɗin mai kyau da ingancin mashin ɗin saman. Domin hanawa da rage torsional nakasawa a lokacin dogon ruwa clamping da yankan, shi wajibi ne don tabbatar da cewa juyawa. shashas na ruwan wukake a gaba da na baya na kayan aiki suna da aikin jujjuyawar aiki tare, kuma manufar ita ce canja ƙarshen clamping ɗaya da ƙarshen fasaha na injinan ruwa na gargajiya.

Hanyar matsawa mai tsauri don gujewa nakasar lankwasa yayin datse ruwan wuka da nakasar tarkace na bayanin martabar ruwa a cikin madaidaiciyar hanya wanda ya haifar da jujjuyawar ƙarshe ɗaya da kuma ƙarshen bibiya yayin aikin jujjuya ruwan ruwa. Don saduwa da buƙatun saka ruwa da matsewa, ɓangaren madaidaicin madaidaicin a ƙarshen madaidaicin ruwa yana da ƙayyadaddun buƙatun daidaiton matsayi dangane da madaidaicin matsayi a ƙarshen gaba.

Bayan an kammala roughing na bayanin martaba, gaba da baya na ruwa saboda nakasar danniya Za a gyara kuskuren daidaiton matsayi tsakanin nassosin sakawa na ƙarshe. Bayan shigar da jigs don ƙirar bayanin martabar ruwa akan rotary shafts a gaba da ƙarshen ƙarshen na'urar, kuma bayan tantance cewa babu kuskuren ta'aziyya a cikin ramukan rotary a gaba da ƙarshen ƙarshen na'urar, daidaiton shigarwa. na gaba da baya maras motsi Ana ganowa kuma an daidaita shi ta amfani da mandrel na musamman. Tabbatar cewa maras motsi a ƙarshen duka biyun suna da ingantacciyar alaƙar daidaiton matsayi, don guje wa ƙarin damuwa na torsional da ke haifar da aikin jujjuyawar gaba da baya na kayan aikin injin saboda rashin daidaituwar matsewar injin. maras motsi. M milling profile na ruwa shi ne a cire babban gefe da barin iri ɗaya gefen machining don gamawa. A karkashin wannan jigo, aikin injiniyan wannan tsari ya kamata ya tabbatar da ingancin injin. Cibiyar haɗin gwiwar axis biyar tana da aikin injin faɗin jere.

Ka'idar ita ce, lokacin da ake niƙa ruwa, cibiyar cibiyar kayan aiki ba ta daidaita da tangent na batu ko saman da ake niƙa ba, amma a cikin hanyar kayan aiki da batu ko saman da ake niƙa. Hanyar al'ada tana a wani kusurwa. Wannan nau'in niƙa yana amfani da injin ƙarshen cylindrical, kuma hanyar niƙa babbar baka ce ta elliptical. Idan aka kwatanta da niƙa na ƙwallon ƙwallon, tsayin bayanin martaba ɗaya ko saman ana niƙa. Dangane da inganci, nisa tsakanin hanyoyin kayan aiki da aka samar ya fi girma. Saboda haka, irin wannan mashin ɗin yana da ingantaccen aikin injin. A cikin injina na gaske, ana amfani da hanyar injin rotary wanda ke motsawa daga wannan ƙarshen zuwa wancan ƙarshen tsawon ruwan wuka, wato, hanyar niƙa karkace. Ta fuskar inganci, hanyar niƙa ta karkace kuma tana da ingantaccen aikin inji idan aka kwatanta da hanyar niƙa mai tsayi. Kyakkyawan niƙa na bayanin martabar ruwa shine don samun mafi girman juzu'i da daidaiton matsayi, kuma a lokaci guda sanya matakin ƙarancin bayanin martaba ya cika wasu buƙatu. Don rage tasirin "sake dawowa" da aka yi ta hanyar yin amfani da kayan aikin ƙarfe na titanium da kuma tasirin kayan aiki na kayan aiki a kan daidaitattun kayan aiki a lokacin yin amfani da bayanan martaba mai girma, kayan aiki dole ne ya kasance mai kaifi kuma ya guje wa tsawaita kayan aiki na kayan aiki. Don wannan dalili, idan zai yiwu, yi amfani da injin ƙarewa don yin niƙa na bayanan martaba. Niƙa na tsayin tsayi na iya amfani da kayan aiki da yawa don niƙa saman baya, saman ganye, gefen shan ruwa, da gefen shaye-shaye, don guje wa lalacewa ta hanyar manyan injina na kayan aiki guda ɗaya, kuma don samar da matakin daidaito a saman saman. ruwa.

Rashin daidaituwa yana dacewa da ƙarshen ƙarshen bayanin martaba. Lokacin niƙa babban titin alloy fan rotor ruwa, don inganta yanayin yanke, duk matakan da za a guje wa lalacewa na kayan aiki ya zama dole. Dangane da zaɓin kayan aikin kayan aiki da ƙayyadaddun bayanai, ana amfani da gabaɗaya mai ƙarfi gami mai rufi cylindrical ball milling cutter don aiwatar da gefen ciki na farantin ruwan wuka, gefen ciki na farantin gefen da bayanin martaba na mika mulki, bayanin martaba na kusa. zuwa farantin gefen 1. Domin ci da shaye gefuna, zaɓi wani karshen niƙa tare da cylindrical saka da kuma m gami mai rufi ruwa ruwa don sarrafa babban- area profile surface na ruwa leaf tukunya da baya.

Zaɓin kayan shafa don yin kayan aikin titanium gami yana da mahimmanci. Guji yin amfani da kayan shafa waɗanda ke da alaƙa da alloys na titanium. A halin yanzu, ana amfani da kayan aikin da aka lulluɓe PVD don sarrafa kayan aikin titanium. Rufin PVD yana da bakin ciki da santsi. Lokacin da aka haɗe su zuwa simintin carbide substrate na kayan aiki, za su kuma haifar da raguwar damuwa. Wannan damuwa yana da kyau don inganta haɓakar lalacewar kayan aiki. PVD Ana iya haɗa shi a hankali zuwa kayan aiki, wanda ke taimakawa wajen kula da siffar yankan kaifi. Kayan aiki na PVD yana da juriya mai kyau na abrasion, ingantaccen kayan sinadarai, kuma ba shi da sauƙi don samar da gefen da aka gina. A lokacin injin, ya kamata a yi amfani da isasshen mai sanyaya don kwantar da kayan aiki da haɓaka tasirin gogayya, zaɓi madaidaicin yankan sigogi, da haɓaka tasirin yanke ƙarfi.

Halayen Ƙarshen CNC na Babban Bayanan Bayanin Fan Blade

Ƙirar bayanin martabar ruwa shine tabbatar da cewa rashin ƙarfi na bayanin martaba da waviness sun dace da buƙatun ƙira, aikin tsarin kayan aiki baya canzawa, kuma ma'auni na geometric da daidaiton matsayi da aka samu ta hanyar niƙa ba su canzawa a zahiri yayin injin.

Don ainihin mashin ɗin, ƙarshen bayanin martabar ruwa yana dogara ne akan cire sauran alamun kayan aiki akan aikin niƙa don cimma ƙaƙƙarfan da ake buƙata da waviness. Adadin cire ƙarfe a kowane gefe na farfajiyar gyare-gyare bai kamata ya fi 0.05MM ba. A halin yanzu, da yin amfani da CNC abrasive bel nika da polishing inji kayan aikin ga ruwa surface karewa ne mafi balagagge hanya ga m machining aikace-aikace, da kuma yin amfani da CNC lu'u-lu'u nika dabaran nika inji kayayyakin aiki, don ruwa surface karewa ne wani gwaji aikace-aikace. Hanya.

Dalilin da yasa aka zaɓi waɗannan hanyoyin mashin ɗin don aikace-aikacen shine saboda suna da halayensu. Da farko, don machining Hanyar CNC abrasive bel nika da polishing inji kayayyakin aiki, yana da wadannan halaye:

- ▶ The abrasive hatsi na abrasive bel yana da kaifi da nika yadda ya dace sosai, wanda ya kai sau 10 na niƙa da 5 sau na talakawa nika dabaran nika;

- ▶ Rikicin da ke tsakanin bel ɗin niƙa da kayan aikin ƙanƙara ne, niƙa yana haifar da ɗan zafi kaɗan, kewayen bel ɗin yana da girma, kuma ƙwayar abrasive tana da tazarar lokaci mai tsawo don zubar da zafi. Abu ne mai sauƙi don samun cikakken sanyaya iska da yankan ruwa, wanda zai iya yadda ya kamata rage nakasawa na workpiece Burns da ablation;

- ▶ Ƙaunar bel mai laushi da tsarin jikin roba a saman ƙafafun aikin yana tabbatar da cewa bel ɗin yana hulɗa da kayan aiki kuma yana da tasiri mai kyau na gudu da gogewa;

- ▶ Abrasive bel nika Akwai barga abrasive kayan aiki size, saboda abrasive bel ne a haɗe zuwa aikin dabaran ga nika, da abrasive kayan aiki size yana da mafi alhẽri kwanciyar hankali.

- ▶ Abrasive bel nika ba za a iya sarrafa na dogon lokaci tare da babban adadin cire, kuma abrasive bel yana dauke da jimlar adadin abrasives yana da iyaka, da kuma dogon lokaci machining tare da babban wuce haddi da cirewa zai yi sauri cinye abrasives, kuma ya zama dole. don katse mashin ɗin kuma a maye gurbin bel mai ƙura.

A sama da aka ambata halaye na abrasive bel nika sa shi yiwuwa ga manyan titanium gami fan ruwa surface polishing gane mechanized samar a karkashin shirin-sarrafawa yanayi. A halin yanzu, akwai hanyoyi guda biyu da za a zaɓa daga hanyar CNC bel ɗin niƙa da ake amfani da su don goge ruwa: ɗaya shine yin amfani da bel ɗin CNC mai bel shida da na'ura mai goge baki, ɗayan kuma shine yin amfani da tsarin bel ɗin CNC na robot CNC. inji. Ayyukan motsi na bel ɗin CNC mai bel guda shida da na'ura mai gogewa yayi kama da cibiyar injin CNC mai axis biyar yayin milling.

Bambancin tsari tsakanin dabaran aikin niƙa bel da aikin injin niƙa na ƙarshe ya sa ya zama dole don daidaita mashin ɗin bayanan martaba zuwa tsarin ruwa. Tare da aikin kusurwar lilo a cikin kwatance 2. Shida-axis CNC abrasive bel nika da polishing inji yana da dual ayyuka na profile nika da polishing. Canjin aikin ya dogara ne akan canjin shugaban wutar lantarki a cikin nau'in niƙa mai ƙarfi da kuma iyo.

A lokacin aikin polishing, ana kunna injin matsi na yau da kullun, don haka canjin matsa lamba na gaba za'a iya sarrafa shi daidai ta hanyar firikwensin matsin lamba, firikwensin ikon niƙa, silinda mai matsa lamba da sauran hanyoyin don daidaitawa da bambanci a cikin girman kowane bayanin martabar ruwa a cikin takamaiman kewayon. Mashin goge goge ba tare da lalata daidaiton bayanin martaba ba. Lokacin yin niƙa na bayanan martaba, injin lamba mai iyo yana kulle don ba da izinin niƙa bayanan martaba.

Tsarin niƙa mai tsauri na bayanin martaba na iya ƙarawa ko maye gurbin halin da ake ciki lokacin da madaidaicin bayanin martaba bai da kyau, kuma girman hatsi na bel ɗin abrasive da aka yi amfani da shi ya kamata a canza bisa ga gefe. Wannan injin ɗin zai canza daidaiton matsayi na asali na girma, kuma dangane da tsarin niƙa, kawar da wuce gona da iri zai haifar da nakasar damuwa. Don haka, ba a ba da shawarar yin amfani da aikin niƙa a ƙarƙashin yanayin cewa aikin niƙa yana da ikon tabbatar da daidaito ba. Robot CNC abrasive bel polishing Hanyar ita ce mutum-mutumi yana riƙe da ruwan wukake kuma yana yin motsi a ƙarƙashin kulawar shirin don yin aikin gyaran gyare-gyare akan na'ura mai kayyade bel. Mashin ɗin yana amfani da fasahar injiniya ta baya. Kafin yin aikin, mutum-mutumi yana riƙe da ɓangaren ɓangarorin ruwa don duba bayanan martabar bayanin martabar, sannan tsarin sarrafa bayanai ya haifar da tsarin sarrafa mashin ɗin, kuma a ƙarshe ya gane goge ruwan a ƙarƙashin ikon shirin. A halin yanzu, saboda ƙayyadaddun daidaiton motsi, hanyar niƙa bel ɗin robot gabaɗaya ana amfani da ita azaman hanyar goge bayanan martaba. Hanyar niƙa na CNC lu'u-lu'u niƙa ƙafafun nasa ne na al'ada wuya da m nika. Na'urar motsin kayan aikin injin da aka yi amfani da shi daidai yake da cibiyar haɗin gwiwar axis biyar. Kayan aikin yankan da ake amfani da shi shine canza mai yankan niƙa a tsaye zuwa saman da aka lulluɓe da lu'u-lu'u foda. Silindrical niƙa dabaran. A lokacin niƙa, ana amfani da fasahar kere kere mai faɗin layi. Irin wannan hanyar mashin ɗin yana da wuya kuma mai tsauri. Saboda dabaran lu'u-lu'u da kanta tana da ƙarancin iska, ba zai iya cimma tasirin ɓarkewar zafi ba ta hanyar adanawa da musayar matsakaicin sanyaya, don haka bai dace da niƙa saman ɓangaren da babban adadin cirewa ba, har ma yana da tsari wanda ke kawar da ƙaramin gefe, kuma yana da sauƙi don ƙona niƙa na saman ruwa na kayan gami na titanium.

Sabili da haka, lokacin amfani da wannan hanyar don aiwatar da ruwan wukake na katako na katako na titanium, ya zama dole don gano madaidaicin yankan da ya fi dacewa da kayan aikin sanyaya na'ura Hanyar dole ne ta kasance mai tasiri sosai. Bugu da ƙari, ƙaƙƙarfan ƙaƙƙarfan kaddarorin niƙa na dabaran lu'u-lu'u akan farfajiyar bayanin martaba kuma suna da takamaiman "gefen" na abin yanka. Kodayake ana iya inganta shi ta hanyar daidaita shirin zuwa ƙayyadaddun ƙayyadaddun ƙafafun niƙa, ba za a iya cire shi gaba ɗaya ba. Tasirin aikin gajiyar ruwa ba shi da kyau, don haka dole ne a ɗauki ƙarin matakan don kawar da "riji". Yana iya zama dole a yi amfani da CNC bel ɗin niƙa da kayan aikin goge goge don ƙarin injina ƙarƙashin ikon shirye-shiryen da suka dace. Bugu da ƙari, yin amfani da kaddarorin ɓarke na kyauta na hanyar busa yashi don ƙarin mashin ɗin ya kamata kuma ya zama hanya mai yiwuwa. Saboda abubuwan da aka ambata a sama na hanyar niƙa lu'u lu'u-lu'u na CNC, aikace-aikacen injin sa yana kan matakin bincike. A halin yanzu, da CNC abrasive bel nika da polishing inji kayan aiki Hanyar zama mafi dace hanya ga polishing na manyan ruwa profiles saboda da yawa abũbuwan amfãni. Babban fa'idarsa shine ana iya amfani dashi don busasshen niƙa da rigar niƙa. Yana kuma iya yin matsananci-ƙananan zafin jiki nika a karkashin CO2 sanyaya, wanda yake da matukar amfani don kauce wa konewa da ablation na babban titanium gami kayan ruwa profile polishing.

Aikace-aikacen injin niƙa da kayan aikin gogewa na CNC ya canza babban gyare-gyaren gyare-gyaren hannu na manyan bayanan martaba, wanda ya taka muhimmiyar rawa wajen inganta ingantaccen samar da manyan ruwan wukake. Haɓakawa da aikace-aikacen fasaha na haɗin gwiwar axis da yawa sun haɓaka daidaito da ingancin ingancin mahimmin hanyar haɗin mashin ɗin manyan injinan fanfofan bayanin martaba, sannan kuma sun sami sakamako mai gamsarwa a cikin ingancin injina. Na yi imanin cewa tare da aiwatar da ci gaba da bincike da haɓaka fasahar kayan aiki, manyan fasahar sarrafa bayanan martabar fan za su bunƙasa a cikin hanyar injina da sarrafa kansa.

Shiga wannan labarin : Nazarin Machining Manyan Titanium Turbine Blades Profile Tsari

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis masu saurin daidaitaccen kayan aikin CNC ciki har da niƙa, juyawa zuwa ƙayyadadden abokin ciniki, Caparfin ƙarfe & kayan aikin filastik tare da haƙurin +/- 0.005 mm.mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis masu saurin daidaitaccen kayan aikin CNC ciki har da niƙa, juyawa zuwa ƙayyadadden abokin ciniki, Caparfin ƙarfe & kayan aikin filastik tare da haƙurin +/- 0.005 mm.mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan