Kpaddamarwar Workpiece da kayan aikinta

Girkawar Mahalli da Kuma kayan aikinsa

|

Hanyar hawa kai tsaye Ana sanya kayan aikin kai tsaye akan tebur ɗin inji ko kayan aiki na gaba ɗaya (kamar kayan haɗi na yau da kullun irin su ƙwanƙwasa-muƙamuƙi uku, ƙwanƙwasa-muƙamuƙi huɗu, masu facin hanci-hanci, jakar wutan lantarki, da sauransu), kuma wani lokacin ana cakuɗe shi ba gano wani daidai, alal misali Ana amfani da chuck-jaw-chuck uku ko electromagnetic chuck don shigar da abin aiki; wani lokacin ya zama dole a daidaita abin aiki daidai da wani wuri ko layin marubuta a jikin abin, sa'annan a matse shi, kamar shigar da abin ɗambar ɗin a kan maƙerin muƙamuƙin huɗu ko a teburin injin. |

Shigar da wurin aiki

Matsayi: Kafin gyara kayan aiki, dole ne a sanya abin ɗora akan tebur ɗin mashin ko abin da zai sanya shi zama daidai.

Bayan an sanya kayan aiki, ana bukatar matse shi domin hana shi kaucewa daga madaidaicin matsayi saboda karfin yankan, nauyi da karfi mara karfi yayin yankan.

Girkawa: dukkanin tsari daga sanyawa zuwa matattarar kayan aiki.

Lokacin shigar da abin aiki, gabaɗaya an daidaita shi da farko sannan a matse shi. Lokacin shigar da kayan aiki a kan ƙwanƙwasa muƙamuƙi uku, sanyawa da ɗaurawa ana yin su a lokaci ɗaya.

Hanyar shigarwa

(1) Hanyar hawa kai tsaye

Ana sanya kayan aikin kai tsaye akan tebur ɗin mashin ko kayan aiki na gaba ɗaya (kamar kayan haɗi na yau da kullun kamar ƙwanƙwasa-muƙamuƙi uku, chuck na jaw-huhu huɗu, faci-hanci hanci, electromagnetic chuck, da sauransu), kuma wani lokacin ana cakuɗa shi ba tare da samun wani madaidaici , alal misali Ana amfani da chuck-jaw-uku ko electromagnetic chuck don shigar da abin aiki; wani lokacin ya zama dole a daidaita abin aiki daidai da wani wuri ko layin magatakarda a jikin abin, sannan a matse shi, kamar shigar da abin ɗamarar a kan ƙuƙashin muƙamuƙin huɗu ko a teburin injin.

Lokacin shigar da kayan aiki ta wannan hanyar, yana da cin lokaci don neman daidaitawa, kuma daidaitaccen wuri yana dogara ne akan daidaitattun kayan aikin ko kayan aikin da aka yi amfani da su, da matakin fasaha na ma'aikata. Daidaitaccen matsayi ba sauki bane garantin kuma yawan aiki yayi ƙaranci, saboda haka yawanci kawai ya dace da sassa ɗaya Smallananan ƙirar tsari.

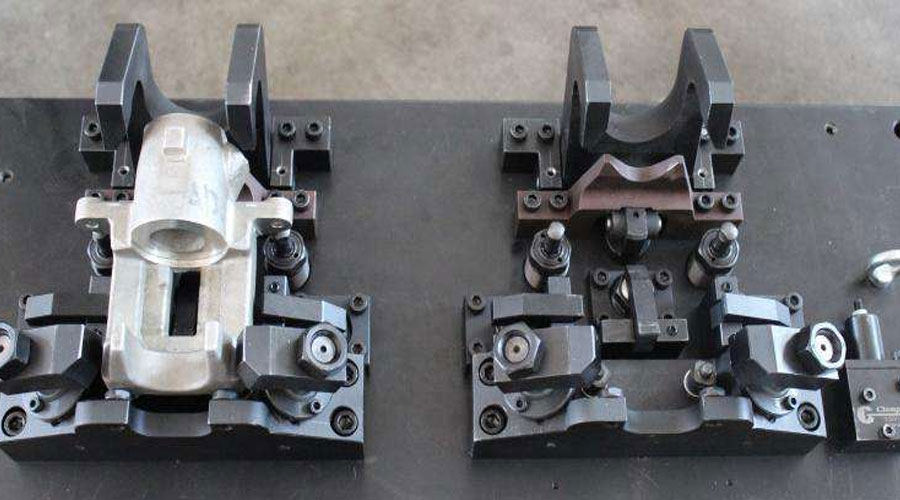

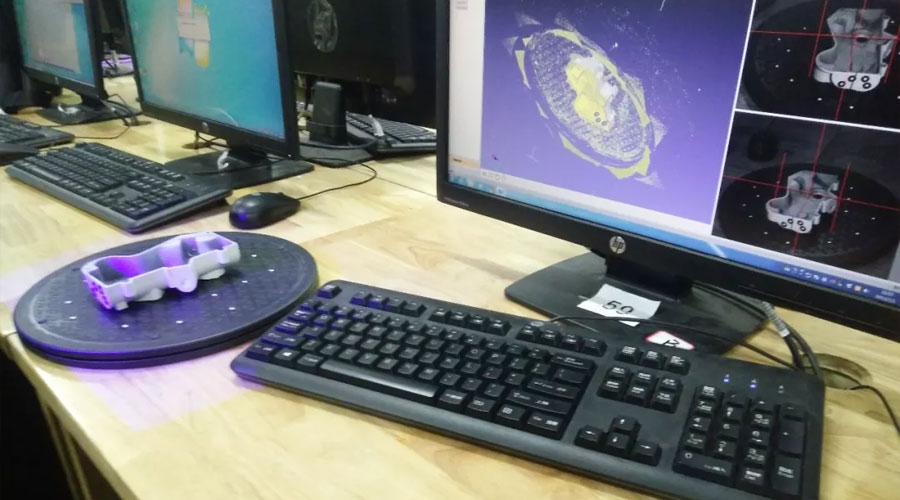

(2) Hanyar tsayarwa ta musamman

Fiirƙirar an tsara ta musamman kuma an kera ta don aikin ɓangaren ɓangare. Ba tare da gyara ba, kuna iya sauri da aminci tabbatar da daidaitaccen matsayi na abin aiki zuwa kayan aikin inji da kayan aiki, kuma kuna iya matsawa da sauri.

Yin amfani da musamman maras motsi don aiwatar da kayan aiki ba kawai zai iya tabbatar da ingancin aikin ba, amma kuma inganta ƙimar samarwa, amma babu wata duniya. Zane, ƙira da kiyaye kayan musamman maras motsi Ana buƙatar takamaiman saka hannun jari, don haka kawai a cikin samar da tsari ko samar da ɗimbin yawa ana iya samun kyakkyawan sakamako.

Rarrabuwa da kayan haɗin kayan aikin inji

Jig da kayan aiki don kayan aiki na inji za a iya raba su zuwa jumloli na gaba ɗaya, kayan aiki na musamman, abubuwan haɗuwa, abubuwan daidaitaccen daidaito da abubuwan rukuni gwargwadon ikon amfani da su.

Dangane da kayan aikin injin da aka yi amfani da su, ana iya rarraba kayan aikin zuwa kayan lathe, kayan aikin injin milling, kayan aikin hakowa (drill ya mutu), kayan inji masu banƙyama (masu mutuƙar mutu), kayan aikin niƙa da kaya kayan aikin inji.

Dangane da tushen wutar lantarki wanda ke haifar da karfi, ana iya raba kayan aikin zuwa kayan aiki na hannu, tsawan pneumatic, kayan aiki na lantarki, kayan lantarki, lantarki da lantarki.

Fia'idar ta musamman tana ƙunshe da waɗannan sassa:

(1) Matsayin sanyawa

Xtureirƙirar yana cikin ma'amala tare da zaɓin zaban wurin zance na ɗakunan aiki don ƙayyade madaidaicin matsayin aikin.

Lokacin da aka sanya abin aiki a cikin jirgin sama, yi amfani da ƙusa mai goyan baya da farantin talla kamar abubuwa masu sanyawa

Lokacin sanya kayan aiki a waje da farfajiyar silinda, ana amfani da toshe mai fasalin V da hannun riga a matsayin tsayayyen kayan aiki

Lokacin da aka sanya abin aiki tare da rami, ana amfani da maƙallan sakawa da sanya matsayi azaman abubuwan sanyawa.

(2) Clamping inji

Tsarin da zai dunkule kuma ya matse abin aiki bayan an sanya shi don hana abin aiki daga matsuguni saboda yankan karfi da sauran rundunonin waje.

Abubuwan da ake amfani da su na yau da kullun sun haɗa da faranti na matsi, faranti na latsawa, hanyoyin karkatar da sihiri, hanyoyin murɗawa, da dai sauransu.

(3) Abun jagora

Bangaren da aka yi amfani da shi don saita kayan aiki da kuma jagorantar kayan aikin zuwa madaidaicin aikin inji

Hannun rawar soja da hannayen jagora galibi ana amfani da su a cikin kayan aikin injin hakowa da kayan haɗin injina masu banƙyama, kuma an fi amfani da bulolin saitin kayan aiki a cikin kayan haɗin injin.

(4) lamunƙwasa sassa da sauran sassan

Unƙwasa sassan ɓangaren matattara. Yi amfani da shi don haɗawa da gyara ɓangaren sanyawa, tsarin matsewa da kuma jagorar jagora, da sauransu, don sanya shi gaba ɗaya, kuma shigar da abin ɗorawa akan kayan aikin inji.

Dangane da abubuwanda ake buƙata na kayan aiki, wani lokacin akwai hanyoyin sarrafa bayanai, maɓallan jagora, ƙarfe mai daidaito da sassan aiki akan tsawan.

Dukan kayan aikin da sassansa dole ne su sami cikakkiyar daidaito da tsauri, kuma tsarin ya zama ya zama karami, fasalin ya zama mai sauki, kuma ya kamata a ɗora kayan aikin kuma a sauke su kuma cire guntu ya zama ya dace.

Alamar aiki da zaɓi

A cikin ƙira da ƙirar sassa, wasu maki, layuka, da yankuna galibi ana amfani dasu don ƙayyade dangantakar lissafi tsakanin abubuwa. Wadannan wuraren, layuka, da yankuna ana kiran su datum.

Alamar alamar: An kasu kashi biyu: ƙirar ƙira da tsarin aiki.

(1) Tushen zane

Tushen zane shine asalin da ake amfani dashi akan zane-zane a yayin zane.

Dangane da ƙirar ƙira don ƙayyade girma da alaƙar matsayi na juna tsakanin abubuwan geometric

(2) Tsarin aiki

Matsakaicin aiki shine ma'aunin da aka yi amfani da shi yayin aiwatar da sassan masana'antu da haɗa na'urori. Matakan aiwatarwa sun kasu kashi biyu na daidaitattun wurare, ma'auni masu aunawa da ma'aunin taro, waɗanda ake amfani dasu don sanyawa, aunawa da duba kayan aiki da kuma haɗuwa da ɓangarori yayin aikin inji.

Matsayi na sanyawa: farfajiyar kayan aiki don ƙayyade matsayin dangi na aikin zuwa kayan mashin da kayan aiki yayin aiki.

Ughuntataccen tunani: Matsayi na sakawa da aka yi amfani da shi a cikin aikin farko shi ne yanayin da ba a san shi ba a kan blank.

Kyakkyawan datum: Tsarin datti da aka yi amfani da shi a cikin matakai na gaba shine ƙirar da aka ƙera.

(3) Tsananin tunani

Zaɓin maɓallin keɓaɓɓen tunani ya kamata ya tabbatar da cewa duk saman injunan suna da isassun alawus na kayan aiki, kuma kowane saman da aka kera yana da takamaiman matsayi zuwa saman da ba a san shi ba.

Principlesayyadaddun ka'idojin zaɓinsa sune kamar haka:

- 1) Zaɓi yanayin da ba a san shi ba kamar yadda yake. Idan akwai abubuwa da yawa wadanda basu dace ba a bangaren, ya kamata ka zabi wurin da yake bukatar daidaiton matsayin juna tare da mashin din a matsayin matattarar magana.

- 2) Zaɓi farfajiyar da ke buƙatar alawus ɗin kayan aiki iri ɗaya a matsayin matattarar tunani, don tabbatar da cewa saman da aka yi amfani da shi azaman maimaita tunani daidai yake a aikin injiniya.

- 3) Don sassan da za'a yi aiki dasu akan dukkan ɗakuna, farfajiyar da ke da ƙaramar tazara da haƙuri dole ne a zaɓi ta azaman matattara mai ma'ana don kauce wa ɓarnar da rashin ƙarancin gefe ya haifar.

- 4) Don yin aikin sanya matsakaicin aiki mai kwari kuma abin dogaro, ana buƙatar cewa zaɓin da aka zaɓa mai laushi ya zama mai santsi da santsi kamar yadda ya yiwu, a'a ƙirƙira an ba da walƙiya, yankan ƙofa da sauran lahani, kuma akwai wadataccen yankin tallafi.

- 5) A cikin girman girman daidai, yawanci ana ba da izinin amfani sau ɗaya kawai. Wannan shi ne saboda mahimmancin tunani ba shi da kyau sosai. Idan ana amfani da wannan maimaita magana sau da yawa, kuskuren wuri tsakanin saiti biyu na kayan masarufi zai zama babba. Sabili da haka, mahimmin bayani Gabaɗaya, baza'a iya sake amfani dashi ba.

Bayanin mai kyau Zaɓin ingantaccen tunani ya kamata ya tabbatar da ingancin aikin injiniya kuma abin dogaro kuma mai dacewa matsewa.

Principlesayyadaddun ka'idojin zaɓinsa sune kamar haka:

- 1) Kamar yadda zai yiwu, zaɓi yanki tare da girma mafi girma azaman abin ƙididdigewa don inganta kwanciyar hankali da daidaito na shigarwa.

- 2) Principlea'idar daidaituwar daidaituwa, gwargwadon yiwuwa, zaɓi ƙirar zane a matsayin matsakaicin matsakaici, watau. Wannan na iya kauce wa kurakuran sanyawa da aka haifar ta hanyar tsara bayanin wuri da bayanin zane.

- 3) A'idar ƙa'ida ta benchmarking. Don wasu daidaitattun wurare a kan sassan, daidaiton matsayin juna sau da yawa yana da manyan buƙatu. Lokacin kammala waɗannan ɗakunan, yakamata a zaɓi ma'anar wuri guda daidai gwargwadon iko don taimakawa tabbatar da daidaito tsakanin juna tsakanin saman.

- 4) Ka'idar tunatar da juna. Lokacin da daidaiton matsayi tsakanin mashinan saman biyu akan abin aiki ya kasance mai tsayi sosai, ana iya amfani da hanyar maimaita injunan biyu da aka sanya su a matsayin matattarar juna.

- 5) Tsarin kai. Lokacin da wasu matakai na kammalawa ke buƙatar ƙarami da gefe ɗaya (kamar narkar da layin dogo), za a iya amfani da farfajiyar da za a ƙera a matsayin matattarar sanyawa, wanda ake kira ka'idar isharar kai. Matsayin matsayi a wannan lokacin ya kamata a tabbatar dashi ta hanyar aikin da ya gabata.

Shiga wannan labarin : Kpaddamarwar Workpiece da kayan aikinta

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan