Me yasa amfani da inconel 718 don kera sassan jirgin sama

Me yasa amfani da inconel 718 don kera sassan jirgin sama

|

Tun da dadewa, mutane sun fara amfani da hanyoyin ba da labari don sarrafa harshe da tsagi akan fayafai na injin turbin gas. Ana gyara ruwa akan faifan injin turbine ta harshe da tsagi. Duk da haka, broaching zai haifar da canje-canje a cikin tsarin saman da kuma ƙananan yadudduka na faifan injin turbin, wanda zai shafi juriya na gajiyar dabaran. |

Sabili da haka, a cikin ingantaccen ƙirar tsarin batsa, yana da matukar mahimmanci a zana ingantaccen tsarin tsarin ƙarfe na ƙarfe na tsagi na tsagi da aka sarrafa ta hanyar bazuwar. A cikin wannan labarin, mun yi amfani da na'urar duba na'urar gani da ido da kuma na'urar duba lantarki microscopy don nazarin metallographic tsarin na surface da subsurface yadudduka na tenon tsagi na Inconel-718 gami faifai na masana'antu gas turbines. An mayar da hankali kan nazarin halaye na lahani da ke haifar da ƙwanƙwasa ƙwanƙwasa da tsagi a saman ƙasa da ƙasan dabaran. A lokaci guda kuma, binciken ya gano girman albarkatun albarkatun kasa γ ", γ 'da δ a saman harshe da tsagi. Lokacin amfani da samfurin FEM na kayan aiki don hango ko hasashen gajiyar rayuwa na faifan ƙafafun, shi Wajibi ne a shigar da waɗannan mahimman ma'auni masu mahimmanci na tsarin ƙarfe.A cikin nazarin tsarin ƙungiya, mun sami lahani irin su kasusuwa da ɓarna, sa'an nan kuma, mun kwatanta ma'auni na halayen (girma da siffar) na waɗannan lahani tare da ka'idojin ƙira da aka bayar ta hanyar. Bugu da ƙari, wuraren da abin ya shafa broaching da Kwatanta kayan asali sun nuna cewa yawan adadin δ hatsi yana da canje-canje a bayyane. Kayayyakin, mun kwatanta juyin halittar taurin microstructure na tsarin karafa akan saman burowa.An yi nazarin tasirin canje-canje.

Inconel-718 alloy wani Ni-Fe-Cr babban zafin jiki ne wanda Kamfanin Nickel na Duniya ya ƙirƙira a cikin 1950s. Wannan hazo hardening gami da zai iya nuna babban yawan amfanin ƙasa danniya da kuma karfi juriya ga gajiya da rarrafe. Saboda girman juriya da iskar shaka da ƙarfi a cikin yanayin zafin jiki, Inconel-718 gami ana amfani da shi sosai a cikin masana'antar sararin samaniya, musamman azaman kayan injin injin injin injin gas. Gabaɗaya magana, dabaran da ruwan wutsiya suna haɗe tare ta hanyar teno mai kama da bishiya mai tsayi, kuma tsarin tsinkewa shine maɓalli don sarrafa rami mai siffar bishiyar a tsaye. Gabaɗaya, damuwar kowa shine tasirin zafin jiki da tashin hankali akan canjin ƙwayar hatsi yayin nakasar zafi. Broaching kuma zai haifar da canje-canje a cikin tsarin ƙarfe na saman da ƙasan ƙafafun, wanda zai shafi juriyar gajiyar dabaran. Duk da haka, a cikin wallafe-wallafen, akwai 'yan takardu kan broaching na Inconel-718 alloy wheels Qualitative and quantitative analysis of canje-canje a microstructure.

Makasudin wannan binciken shine don bayyanawa da ƙididdige tsarin ƙirar ƙarfe na saman da ƙasan saman tsagi na dendritic mai tsayi na Inconel-718 alloy wheel. Musamman ma, an yi rikodin bayanin da ƙididdigar ƙididdiga na lahani da aka haifar da tsarin broaching a kan saman da kuma ƙananan ƙananan faifan diski, kuma an yi nazarin girman hatsi da halayen hatsi na yankin mashin.

Hanyar Gwaji

Mun katse wani ɓangare na inconel-718 alloy wheel don bincike (Hoto 1). Kamar yadda aka nuna a cikin Hoto 2, muna amfani da hanyar EDM don ɗaukar samfurori na ƙarfe daga farko, tsakiya da wutsiya na tsakiya na tsakiya.

Domin saduwa da buƙatun nazarin metallographic, bayan an daidaita samfurin, za ta bi ta hanyar sarrafawa ta atomatik na niƙa da gogewa. Lokacin yashi, 320, 400, 600 da 1200 sandpaper za a yi amfani da su. Bayan gogewa, samfurin za a goge shi akan ulun MD tare da dakatarwar lu'u-lu'u 1 μm azaman ruwan gogewa na mintuna 2. Domin samun damar kiyaye iyakokin hatsi tare da na'urar duba microscope (SEM), samfurin za a yi shi a cikin maganin oxalic acid a ƙarfin lantarki na 4V na 20-40 seconds. Domin kama halayen γ 'da γ' tare da babban ma'ana, samfurin yana buƙatar zama galvanic etched a cikin wani ƙarfin lantarki 10V bayani (8ml H2SO4 da 100ml H2O) na 20 seconds, da na'urar duba microscope sanye take da wani scanning watsi gun. (FEG) .

Lokacin nazarin lahani tare da SEM, samfurin yana buƙatar a haɗa shi da lantarki a cikin maganin 3V na ƙarfin lantarki (5g CuCl2, 100ml HCL da 100ml ethanol) na 10 seconds. Yi amfani da hanyar bambancin tsayi don samun girman hatsi. Yi amfani da ASTM don samun juzu'in juzu'in hatsi daban-daban: E562 yana ɗauka cewa ɓangaren yanki yayi daidai da juzu'in ƙara. An auna girman hatsi daban-daban tare da software na binciken hoto na Clex. Don samun sakamako na ƙididdiga na wakilai, dole ne a yi amfani da aƙalla zane-zane na metallographic 6 don ƙayyade girman da halaye na hatsi daban-daban.

Aƙalla samfuran 5 na kowane samfurin yakamata a ɗauki su don ma'aunin taurin Rockwell, sannan a ƙididdige matsakaicin ƙimar kowane samfurin. A cikin gwaje-gwajen, nisa tsakanin kasusuwa yawanci ya fi sau 5 diamita na karce. Domin kwatanta da taurin dabi'u a cikin wallafe-wallafe, Rockwell A taurin dabi'u yana buƙatar a canza shi zuwa taurin Vickers, ASTM: E140.

Lalacewar Bincike

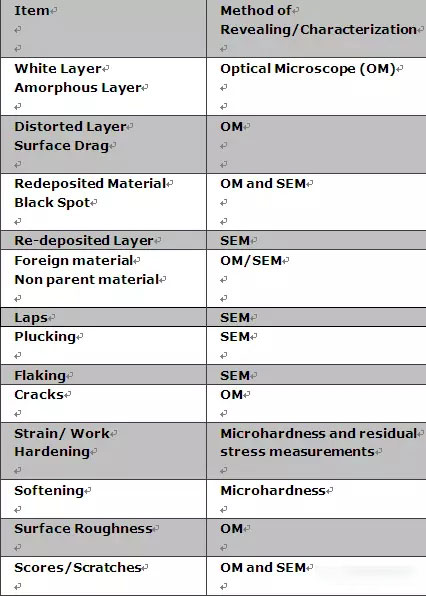

A cikin wannan binciken, mun yi nazari akai-akai akan lahani a cikin layin tsakiyar harshe da tsagi. Fiye da daidai, mun lura kuma mun ƙididdige farkon, tsakiya da ƙarshen broaching. Shafin 1 yana nuna nau'ikan lahani daban-daban da aka haɗa a cikin tsagi na dendritic na tsayin daka na inconel-718 alloy wheels. Ya kamata a ambaci cewa a cikin samfurori na bincike, ba mu lura da lahani irin su farin Layer ba, Layer marar haila, biomass na biyu, baƙar fata, sake sake tarawa, al'amuran waje, da fasa.

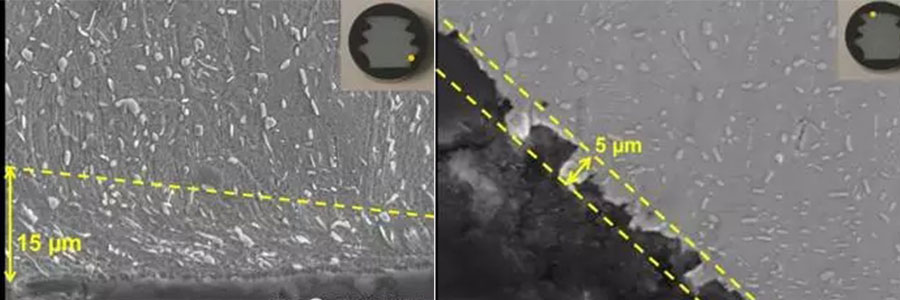

Figures 3 zuwa 6 suna nuna wasu lahani da aka gani. Hoto na 3 yana nuna zazzagewar, kamar ƙananan ramukan da ke bayyana a saman injin da aka kera. Lalle ne, karce shine mafi yawan lahani na saman. Kowa ya san cewa inconel-718 gami yana taurare da injina saboda saurin taurin injinsa yayin aiki. Daban-daban kayan aiki kayan aiki da broaching yanayi, da surface na gami za su ƙara gefen lalacewa, pitting da punching. Duk da haka, a cikin duk samfuran bincike, iyakar yarda da zurfin yashwa ya kasance ƙasa da ƙira. Hakazalika, kamar yadda aka nuna a hoto na 4, ana nuna hoton murɗaɗɗen. A cikin wannan Layer (7 μm fadi), lokaci na δ yana da tsari na musamman. Ana samun sauƙin samun wannan al'amari a saman harshe da tsagi, wanda ƙila yana da alaƙa da damuwa ta hanyar bazuwa a wannan yanki.

Mafi ƙanƙanta saman harshe da tsagi (Hoto na 5) yana a farkon da ƙarshen ƙwanƙwasa. Hakazalika, kamar yadda aka nuna a cikin Hoto na 6, akwai wani lahani da ake kira rashin cikaccen rabuwar kayan, kama da karaya, amma bai fado daga saman motar ba. Wannan sabon abu yana wanzu a cikin duk samfurori. Irin waɗannan lahani suna da matsakaicin tsayi na 25 μm, kuma halayensu (girman da ilimin halittar jiki) sun bambanta. Wannan lahani ya samo asali ne daga ingancin broaching, kuma tasirinsa akan rayuwar roulette ya rage don a kara nazari.

Shiga wannan labarin : Me yasa amfani da inconel 718 don kera sassan jirgin sama

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan