Ingantaccen machining Na Titanium Alloy Aircraft sassa

Ingantaccen machining Na Titanium Alloy Aircraft sassa

|

Titanium alloy yana da fa'idodin ƙarancin ƙima da juriya na lalata, kuma ana amfani da shi sosai wajen kera jikin jirgin, amma yana da saurin lalacewa yayin injin cnc, kuma daidaiton injin ɗin yana da wahala a ba da garanti. Don haka, ya zama dole a yi amfani da fasahar zamani na zamani da ingantattun ababen more rayuwa don tsara ingantattun hanyoyin sarrafa injina, da kuma inganta ingantaccen aikin injin gabaɗaya da inganci ta hanyar. Cibiyar CNC kayan aiki. Bincike mai zurfi tare da titanium kayan aikin gami hanyoyin suna da nufin inganta ingantattun injinan sassa masu alaƙa |

A matsayin wani nau'i na nau'i na kayan aiki mai ƙarfi, sassan alloy na titanium suna da ƙimar aikace-aikacen musamman a cikin sassan jirgin sama filin. Hanyoyin injuna na gargajiya ba su dace da samar da buƙatun tsarin jiragen sama na zamani ba. Sabili da haka, yin amfani da sassan alloy na titanium na iya biyan bukatun ci gaban jirgin sama zuwa mafi girma. An yi amfani da sassan alloy na titanium sosai wajen kera jiragen sama. Misali, ana iya amfani da sukurori da goro don gyara manyan firam ɗin fuselage, da mahimman sassa kamar ruwan injina da saukowa. kaya za a iya yi da titanium gami kayan.

Filayen aikace-aikacen da fa'idodin sassan alloy na titanium

1.1 Filin aikace-aikacen sassan alloy Titanium

Dauki jirgin fasinja na B777 a matsayin misali. Ana amfani da simintin gyare-gyare na titanium a cikin kera firam ɗin hawa jirgin sama. Ana iya ganin cewa a cikin kera jiragen sama na jama'a, fasahar aikace-aikacen kayan aikin titanium alloy sun kasance balagagge. Bugu da kari, sassan gami da titanium suma suna da matukar muhimmanci ga ci gaban masana'antar zirga-zirgar jiragen sama. Misali, Kamfanin Doncasters na Turai yana amfani da fasahar simintin simintin centrifugal don amfani da gami na titanium zuwa karfin birki.

1.2 aikace-aikace abũbuwan amfãni daga titanium gami sassa

Titanium alloy sassa suna da fa'idodin fasaha masu zuwa:

- Na farko, babu buƙatar yin amfani da gyare-gyare a lokacin aikin gyare-gyare;

- Na biyu, babu buƙatar saka hannun jari mai yawa da kuma kuɗi a cikin matakin shiri na farko;

- Na uku, zai iya inganta ingantaccen amfani da kayan aiki yadda ya kamata. Sassan gami da Titanium ba wai kawai inganta aikin aminci na kayan aikin jirgin sama ba, har ma da rage adadin abubuwan da aka haɗa, da yadda ya kamata ya adana lokacin taro na hannu, da samun tasirin haɓaka hanyoyin samun kuɗi da inganci.

Fasalolin jirgin sama titanium gami sassa

2.1 ba sauƙin lalacewa ba

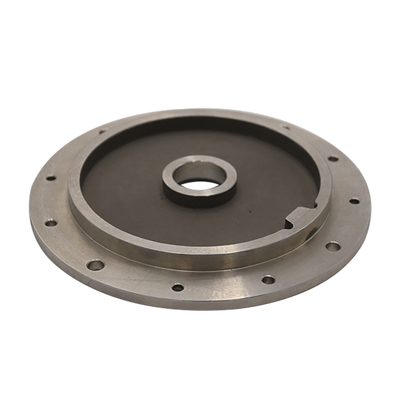

Titanium alloy kayan yana da mafi girma ƙarfi da thermal ƙarfi, kuma yana da ƙananan yawa. Idan aka kwatanta da kayan karfe, kashi 60% ne kawai na yawan ƙarfe. Wannan yana sanya kayan haɗin gwal na titanium ba tare da matsalolin nakasa ba ko da a yanayin zafi na 300 ° C zuwa 500 ° C. Tsarin alloy na titanium na wani nau'in injin jirgin sama ana sarrafa shi ta hanyar TC4 titanium gami ƙirƙiras. Matsakaicin nauyin kilogiram 19.987, nisa shine 600mm, tsayinsa kuma shine 2800mm, amma kaurin bangon shine kawai 1.50mm.

2.2 low zafin jiki juriya

Titanium alloy yana da ƙananan juriya na zafin jiki, wato, har yanzu yana iya kula da kayan aikin injinsa a ƙarƙashin ƙananan yanayin zafi ko ƙarancin zafi. Abu ne mai ƙarfi da ƙarfin juriya mai ƙarancin zafi. Dangane da gwaje-gwaje masu alaƙa, an san cewa alloy titanium yana a -196 ° C. A ƙasa, ƙarfin ƙarfi σb shine 1207Pa.

2.3 mai ƙarfi juriya na lalata

Ana iya amfani da sassan alloy na titanium a cikin filin jirgin sama, dalili mai mahimmanci shine yana da juriya na lalata. Lokacin da jirgin ke tashi a tsayi mai tsayi, abubuwan da ke cikin iska za su yi wani mummunan tasiri a saman jirgin. Sassan gami na Titanium na iya magance wannan koma baya yadda ya kamata da kuma tabbatar da amincin jirgin.

2.4 Tare da sinadarai

Titanium alloys na iya amsawa tare da nau'ikan abubuwan ƙarfe iri-iri. Tare da taimakon sinadaran halayen, ana iya haɓaka kayan aikin injiniya na alloys titanium. Alal misali, a cikin yanayin zafi mai girma sama da 600 ° C, titanium alloys na iya amsawa tare da oxygen don samar da Layer oxide daidai.

2.5 low thermal watsin

Aiwatar da sassan alloy na titanium akan jiragen sama na iya rage yiwuwar gazawar sassan jirgin sama yadda ya kamata, da kuma guje wa zafin da ya wuce kima na sassan jirgin da ke shafar aikace-aikacen al'ada na sauran sassan.

2.6 Ƙananan ma'auni na elasticity

A cikin aiwatar da yin amfani da sassan alloy na titanium, kar a sarrafa su cikin sassan siriri. Wannan shi ne saboda ma'aunin ƙarfe na ƙarfe na titanium yana da ƙananan ƙananan kuma yana da sauƙi don lalata. Bugu da kari, a cikin kayan aikin titanium tsari, saboda babban rebound na titanium gami, yana da sauƙin sa kayan aiki.

Ma'auni da Ma'auni na Ƙirƙirar Ƙira Titanium Alloy Parts

Masana'antar zirga-zirgar jiragen sama ta kasar Sin tana mai da hankali sosai kan yadda ake amfani da albarkatun kasa, kuma aikin R&D ya fi mayar da hankali ne kan raya tsari da yin amfani da su, domin inganta ayyukan jiragen sama.

3.1 Fadada filin amfani da simintin gyare-gyare na titanium gami

Idan aka kwatanta da sauran sassan titanium, Hanyar simintin saka hannun jari yana da fa'idodi na musamman:

- Girman simintin gyare-gyare daidai ne, saman yana da ɗan santsi, kuma rashin ƙarfi yana da ƙasa;

- Yana iya jefa simintin gyare-gyare masu rikitarwa;

- Yayin haɓaka ƙimar amfani da albarkatun ƙarfe, yana iya haɓaka sassaucin samarwa da daidaitawa.

Duk da haka, a cikin ainihin aikace-aikacen aikace-aikacen, ƙarfin ƙarfe na titanium ba zai iya cika bukatun aikin jirgin sama ba. Sabili da haka, ya kamata a mayar da hankali kan inganta ƙarfin ƙarfin ƙarfe na titanium a lokacin bincike da ci gaba. Haɓaka saurin haɓaka fasahar simintin simintin simintin simintin ƙarfe a cikin ƙasata yana ci gaba da karuwa a cikin 'yan shekarun nan. A kan haka, an yi amfani da ƙugiya mai wuce gona da iri a filin jirgin sama. Saboda yawan buƙatun jirgin sama na sassan alloy na titanium, ƙirƙira adadin sassan titin alloy na ƙasata ya yi ƙasa kaɗan. Don haka, dole ne a yi amfani da kimiyya da fasaha don inganta matakin simintin gyare-gyare, da rage farashin samar da kayayyaki da kuma zagayowar samarwa, da cimma burin samar da jama'a. .

3.2 Rage farashin ci gaba

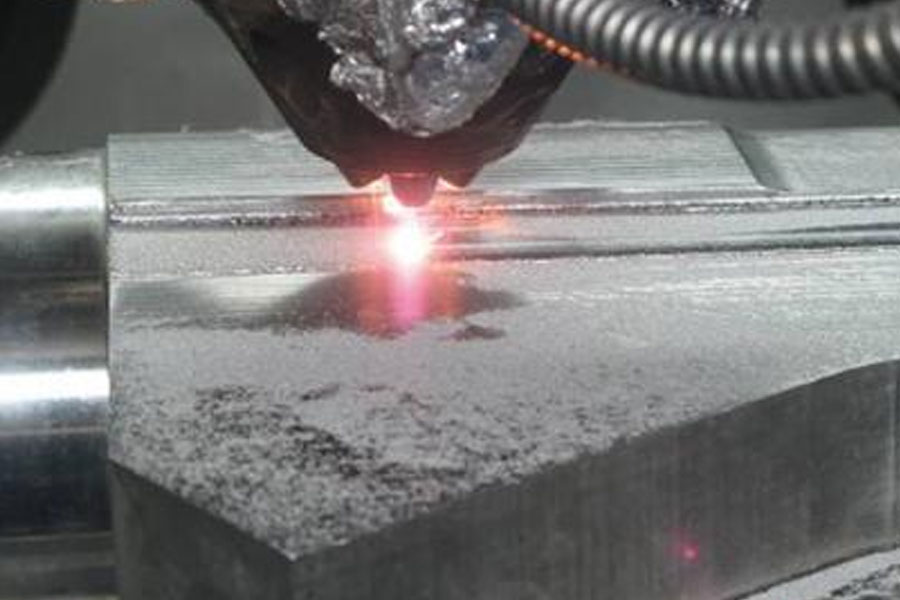

A kan babban iko Laser cladding da m prototyping, titanium gami foda Laser forming fasahar da aka yadu amfani. Wannan fasaha tana amfani da katako mai ƙarfi na Laser don narkar da foda na titanium gami da ƙarfafa shi a kan substrate mai siffar ƙananan ɗigon ruwa, sannan kuma ya dogara da fasahar sarrafa kwamfuta don sa kan Laser ya motsa akai-akai, ta haka ne ya tattara Layer ta Layer, kuma a karshe sami samfurin titanium gami da ake buƙata.

A halin yanzu, an inganta aikin gaba ɗaya na tsarin haɗin ginin titanium, kuma nauyin ɓangaren da kansa ya ragu sosai, wanda filin jirgin sama ya fi dacewa da shi. da abubuwan V a cikin gami da titanium suna da tsada sosai, wanda ke haifar da hauhawar farashin albarkatun ƙasa.

Don haka, gami da haɗin gwiwar jiragen sama na titanium tare da saka hannun jari mai rahusa ya jawo hankali sosai. A halin yanzu, masu bincike sun gano cewa za'a iya amfani da abubuwan Fe don maye gurbin manyan kayan Nb, Mo da V, wanda ba zai iya tabbatar da aikin kayan aiki kawai ba, amma har ma da rage yawan farashin shigarwa na kayan aikin titanium alloy.

3.3 Rarraba da hanyar kariya ta saman

A cikin bincike na saman Layer na BT3-1 da OT4-1, ana iya ƙaddamar da cewa rarraba hydrogen a cikin saman Layer yana da rikitarwa, kuma abun ciki na hydrogen zai kara karuwa a hankali, kuma lokacin da ya kai matsakaicin darajar, shi zai ragu daidai. A halin yanzu, Laser uku-girma kafa fasaha da titanium gami sassa da aka yadda ya kamata a hade, da kuma manyan sikelin titanium gami main. ɗauka an ƙera abubuwan da ake buƙata don jirgin sama.

3.4 Haɓaka abubuwan amfani da ƙarfe na ƙirƙira mai zafi ya mutu

Hanya mafi inganci don haɓaka ƙimar amfani da ƙarfe shine yin amfani da ƙarancin iskar oxygen da dumama mara amfani. Domin titanium gami, dumama da blank tare da bushe iska iya yadda ya kamata warware wannan matsala. Dangane da bincike mai alaƙa, lokacin dumama a cikin tanderun lantarki, yakamata a sarrafa zafin jiki a 950 ℃~980 ℃. Bugu da kari, ta hanyar gudanar da gwaje-gwaje a kan BT20 da OT4-1 (TC1), dumama duk samfurori da kuma mutu ƙirƙira iri ɗaya, za a iya gano cewa ƙananan zafin jiki pre-oxidized ulu surface na blank nuna m sakamako, wanda take kaiwa zuwa ga Ƙarshe cewa Layer na oxide da yanayin jikewar iskar gas suna da tasiri mai mahimmanci akan kayan aikin injiniya.

Kammalawa

A cikin ci gaban ci gaban kimiyya da fasaha, yawancin kamfanoni sun kammala sauye-sauyen su, kuma masana'antar aluminum ta ƙasata ta sami sakamako mai kyau. A cikin saurin bunƙasa tattalin arziƙi, masana'antar gami na titanium na ci gaba da bunƙasa ta fuskar makamashin da za a iya sabuntawa, da ba da damar yin amfani da sassan gami da yin amfani da su yadda ya kamata a fagage da dama, da aza harsashi mai ƙarfi na bunƙasa tanadin makamashi da rage fitar da iska.

Shiga wannan labarin : Ingantaccen machining Na Titanium Alloy Aircraft sassa

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis masu saurin daidaitaccen kayan aikin CNC ciki har da niƙa, juyawa zuwa ƙayyadadden abokin ciniki, Caparfin ƙarfe & kayan aikin filastik tare da haƙurin +/- 0.005 mm.mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis masu saurin daidaitaccen kayan aikin CNC ciki har da niƙa, juyawa zuwa ƙayyadadden abokin ciniki, Caparfin ƙarfe & kayan aikin filastik tare da haƙurin +/- 0.005 mm.mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan