Tsarin Gudanar da Software Don CNC Juya Sassan da Ba Da'ira ba

Tsarin Gudanar da Software Don CNC Juya Sassan da Ba Da'ira ba

|

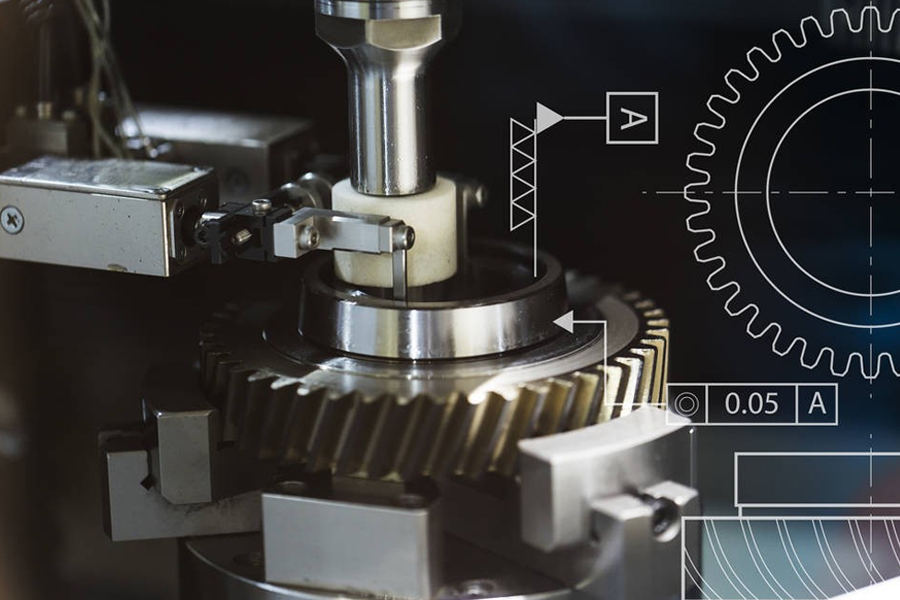

Piston wani muhimmin sashi ne na injin konewa na ciki kuma yanki ne na yau da kullun wanda ba madauwari ba. Matsayin haɗin kai tsakanin fistan da silinda shine muhimmin ma'auni don auna ingancin injin. A zamanin yau, fistan ɗin ellipse na gama gari na yau da kullun ana sarrafa shi ta masana'antun da yawa ta amfani da hanyar bayyanawa. Duk da haka, tun lokacin da tsarin ƙididdiga mai wuya ya buƙaci yin amfani da injiniyoyi ko matsa lamba na hydraulic don cimma nasarar bayanan da aka biyo baya, yana da wuya a kara inganta daidaito da inganci na bayanin martaba, kuma ƙaddamar da mashin ɗin yana da wuyar gaske kuma farashin masana'anta yana da tsada. Sabili da haka, ana buƙatar ƙirar sabon nau'in lathe CNC don saduwa da mashin ɗin na musamman na convex da piston madauwari mai ma'ana. |

Piston wani muhimmin sashi ne na injin konewa na ciki kuma yanki ne na yau da kullun wanda ba madauwari ba. Matsayin haɗin kai tsakanin fistan da silinda shine muhimmin ma'auni don auna ingancin injin. A zamanin yau, fistan ɗin ellipse na gama gari na yau da kullun ana sarrafa shi ta masana'antun da yawa ta amfani da hanyar bayyanawa. Duk da haka, tun lokacin da tsarin ƙididdiga mai wuya ya buƙaci yin amfani da injiniyoyi ko matsa lamba na hydraulic don cimma nasarar bayanan da aka biyo baya, yana da wuya a kara inganta daidaito da inganci na bayanin martaba, kuma ƙaddamar da mashin ɗin yana da wuyar gaske kuma farashin masana'anta yana da tsada. Sabili da haka, ana buƙatar ƙirar sabon nau'in lathe CNC don saduwa da mashin ɗin na musamman na convex da piston madauwari mai ma'ana.

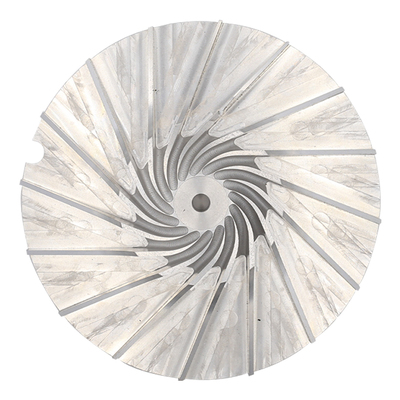

Haɓaka fasahar motar linzamin kwamfuta tare da halayen amsa mitar ya sa wannan buƙatar ta yiwu. A lokacin sarrafawa, ana shigar da sassan da aka sarrafa akan igiya na kayan aikin injin kuma suna juyawa tare da sandal, kuma ana shigar da kayan aiki akan injin mai linzamin kwamfuta, kuma injin ɗin yana da ɗanɗano sassan injinan da aka kera suna jujjuya radially. Saboda tsananin sarkakiyar sifar piston mai canzawa ta tsakiya-convex, adadin bayanan da ake buƙatar sarrafa su yayin tsaka-tsaki yana da girma, kuma saurin amsawa yana da matukar buƙata.

Bugu da kari, a lokacin sarrafa fistan, biyu daban-daban Motors bukatar a sarrafa a lokaci guda, daya matsayi servo, da kuma sauran - na musamman servo linear motor don sarrafa wadanda ba madauwari giciye-sections. Babban manufar CNC software ba zai iya cika wannan buƙatu na musamman don sarrafa pistons ba. Tsarin software da aka gabatar a cikin wannan labarin yana ɗaukar yaren C da yaren taro gauraye shirye-shirye, kuma yana ɗaukar ƙirar ƙira mai zaman kanta, wanda mafi kyawun warware alaƙar jujjuyawar igiya da ciyarwar linzamin kayan aiki.

1 Gabaɗaya ƙirar tsarin

Mai watsa shiri na wannan tsarin yana ɗaukar ikon sarrafa masana'antu 586, kuma ana adana software na tsarin a cikin rumbun kwamfutarka na microcomputer. Bayan an fara tsarin, mai amfani zai iya yin ayyuka daban-daban ta menu. Tsarin yana da ayyuka na CNC irin su shirin sarrafa karatu, haɗawa, kwaikwaiyo, samar da bayanan sarrafa piston, sarrafa motar linzamin kwamfuta, interpolation, M, S, T a cikin matsayi, da dai sauransu.

Software na tsarin yana ɗaukar ƙira na matsayi da na zamani. A tsarin software za a iya raba da dama kayayyaki bisa ga ayyuka, kuma kowane module za a iya edited da kuma harhada dabam. Ana wuce bayanai a tsakanin su ta hanyar sigogi ko fayilolin bayanai, kuma ƙari, gyare-gyare, da gogewa na tsarin ba ya shafar wasu kayayyaki. Software na tsarin ya kasu kashi-kashi na mu'ujiza, Layer na tarawa, Layer na sarrafawa da Layer na taimako, kuma ayyukan kowane bangare suna da 'yanci.

2 Tsarin tsarin da halaye

Ana iya ganin tsarin ya ƙunshi nau'o'i shida, waɗanda ake amfani da su sosai wajen kera injiniyoyi. Koyaya, farashin gabaɗaya ya ninka sau 5 zuwa 10 na lathes na yau da kullun. Idan wani karo ya faru yayin sarrafawa, wutan lantarki zai lalata daidaiton samfurin kuma ya haifar da sharar gida. A cikin mawuyacin hali, kayan aikin injin za su lalace, haifar da babban asarar tattalin arziki da raunin mutum.

Bayan dubawa da bincike, marubucin ya taƙaita dama da dama don yin karo a kan lathes CNC, da kuma ba da shawarar hanyoyin da za a guje wa karo lokacin da ake tsara lathes na CNC.

1 Lokacin amfani da umurnin G00, mai yiyuwa ne karo da juna. Kamar yadda aka nuna, aikin aikin yana buƙatar tsagewa, asalin asalin aikin yana kan ƙarshen dama, kuma wurin canza kayan aiki shine lokacin da aka kammala aikin tsagi, don adana lokaci, Ina so tip ɗin kayan aiki ya motsa daga farawa. nufi fl. Lokacin isa wurin canjin kayan aiki>1, yi amfani da sashin shirin N150G00X80Z50 don kammala janyewar kayan aikin. Idan ana la'akari da hanyar a matsayin madaidaiciyar layi, da alama babu matsala, amma ainihin hanyar tip kayan aiki shine B da layi (kamar aikin taimakon lokaci. A cikin wannan tsarin, mai amfani zai iya Farko, bisa ga takamaiman bukatun. Daga cikin zanen sashin, shigar da bayanai daban-daban da aikin kowane aiki ana aiwatar da su a cikin layin sadarwa ta hanyar tattaunawa ta injin injin. , wanda ya haɗa da fassarar tsarin tsarin tushen tushen NC, daidaitawa da juyawa, gano kuskure, ƙididdigar bayanai da lissafin ƙididdiga, m interpolation, da dai sauransu; ; a cikin Layer Layer, Yana ba da ayyuka daban-daban na taimako waɗanda suka dace da aikin tsarin da aikin mai amfani. Dukkan tsarin ana sarrafa shi ta hanyar maɓalli da linzamin kwamfuta Don zaɓar menu, masu amfani kawai suna buƙatar danna cu. rsor, hotkey ko linzamin kwamfuta. Bugu da ƙari, tsarin yana da Ayyukan zane mai ƙarfi mafi ƙarfi yana ba da nunin hoto na bayanan shigarwar piston, aikin kwaikwayo mai ƙarfi na hanyar motsi na kayan aiki, da nau'i mai mahimmanci yana nuna bayanan shigarwa da zane-zane na kayan aiki la). Babu shakka, kayan aikin yana buƙatar zama Idan matakin matakin na kayan aikin ya yi karo, kayan aikin da kayan aikin za su lalace, kuma daidaiton injin ɗin zai lalace.

Bambanci tsakanin umarnin saka ma'ana G00 da kuma umarnin haɗakar layi na G01 ba gudu ba ne kawai, amma mafi mahimmancin abu shine cewa yanayin tsohon gabaɗaya ba madaidaiciyar layi ba ne, kuma ƙarshen dole ne ya isa ƙarshen ƙarshen a madaidaiciya. layi. Idan aka yi kuskure cewa G00 dole ne ya isa ƙarshen ƙarshen a madaidaiciyar layi, yana da haɗari sosai. Yanayin tip ɗin kayan aiki yana motsawa daga ainihin matsayi zuwa matsayi na matsayi da aka umarta a cikin G00 block shine gaba ɗaya sassan layi guda biyu madaidaiciya tare da kusurwoyi daban-daban, wato, yana buƙatar juyawa sau ɗaya a cikin tafiyar tafiya, da kuma hanyoyin X da Z. na post ɗin kayan aiki duka an saita su bisa ga saitunan su. Yi tafiya a cikin sauri, kowanne har sai Zengtong a wannan hanya ya ƙare.

Don aiwatar da janyewar, ana nuna hanyar motsi na kayan aiki a cikin Hoto lb, ta yadda za a iya guje wa karo.

Waƙar da ke gudana tana bawa masu amfani damar nemo kurakuran aiki cikin lokaci.

Takaita 3

Tsarin yana ɗaukar hanyar ƙirar sama-sama, ƙirar abokantaka, aikin taimako na ainihi, aikin simintin hoto, aikin ƙararrawa, da dai sauransu, wanda zai iya adana lokaci mai yawa da aka kashe akan gudanar da bincike da gwajin yankan gwaji akan kayan aikin injin. . Amfanin amfani da kayan aikin injin yana rage farashin samarwa. An yi nasarar gwada tsarin a masana'antar kayan aikin injin da yawa.

Shiga wannan labarin : Tsarin Gudanar da Software Don CNC Juya Sassan da Ba Da'ira ba

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

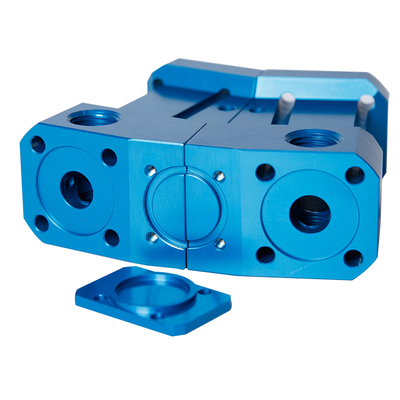

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan