Matsalolin gama gari Da Magani Ga Bakin Karfe Zurfin Zane Mold

Matsalolin gama gari Da Magani Ga Bakin Karfe Zurfin Zane Mold

|

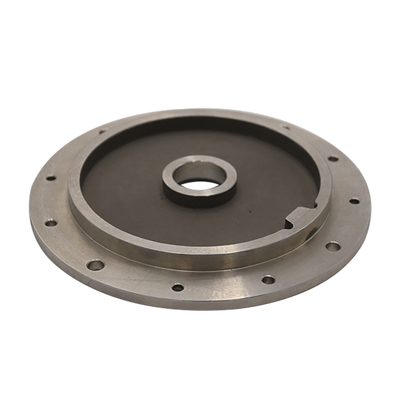

Bakin karfe ana amfani dashi sosai a cikin samar da masana'antu saboda kyakkyawan aikin sa, amma nasa stam aikin ba shi da kyau, saman sassan yana da sauƙin karce, kuma ƙirar yana da haɗari ga ciwace-ciwacen ƙwayar cuta, wanda ke tasiri sosai ga ingancin samfuran. stam da ingancin samarwa. Wannan yana buƙatar stam tsari don farawa daga al'amurran mold tsarin, mold kayan, zafi magani da lubrication, inganta ingancin sassa da mold rayuwa, kuma mafi warware matsalolin a cikin bakin karfe. stam tsari. |

Abubuwan Hatimi Na Bakin Karfe Sheet

- (1) Rashin lahani kamar babban wurin samar da albarkatu, babban tauri, gagarumin tasirin sanyi, da fasa.

- (2) Ƙarfin zafin jiki ya fi muni fiye da na ƙarfe na carbon na yau da kullum, wanda ke haifar da babban ƙarfin lalacewa, ƙarfin bugawa da ƙarfin zane.

- (3) Nakasar filastik tana da ƙarfi sosai yayin zane mai zurfi, kuma farantin bakin ciki yana da sauƙin murƙushewa ko faɗuwa yayin zane mai zurfi.

- (4) Ciwace-ciwacen mannewa suna da wuya su bayyana a cikin zurfin zane mai mutuƙar mutuwa, suna haifar da ɓarna mai tsanani akan diamita na waje na ɓangaren.

- (5) Yana da wuya a cimma siffar da ake tsammani a lokacin zane mai zurfi.

Maganin Stamping Bakin Karfe Sheet

Matsalolin mannewa nodules a cikin zurfin zane na zanen bakin karfe koyaushe yana addabar wurin samarwa kuma yana kawo matsala ga masu samarwa. Duk da haka, saboda samuwar nodules na adhesion ya ƙunshi matsalolin tribological, akwai abubuwa masu tasiri da yawa. A halin yanzu, za mu iya ba da shawarar matakan kawai daga kusurwoyi daban-daban don hana samuwar da rage ciwace-ciwacen mannewa.

Zaɓin kayan abu da maganin zafi na sashin aiki na mold

Dangane da matsalar ƙwayar cuta ta mannewa, zaɓin kayan ƙirar yakamata ya dogara ne akan alaƙar da ke tsakanin takaddar bakin karfe da kayan ƙira. Ya kamata a ba da hankali ga maki biyu: ɗaya shine zaɓin kayan ƙira tare da juriya mai ƙarfi ga mannewa, ɗayan kuma abu ne mai jurewa da juriya. Gabaɗaya magana, karafa masu nau'in nau'in ƙoshin ƙarfe iri ɗaya, tazarar raƙuman ruwa, ƙarfin lantarki, da kaddarorin electrochemical suna da jan hankali na juna, ƙarfin narkewa mai ƙarfi, da sauƙin mannewa tare, yana haifar da mafi girman juzu'i. Solubility na juna na Cr, Ni da Fe yana da girma, don haka ya fi dacewa da haɗin nodules lokacin zana da karfe mutu. Ayyuka sun tabbatar da cewa yin amfani da simintin gyaran gyare-gyare na aluminum da tagulla na duralumin yana da sakamako mai kyau na anti-stick; yin amfani da tungsten carbide karfe bonded cemented carbide don yin mutu yana da rai na sau da yawa fiye da na Cr12Mov taushi nitriding, kuma ba ya tsaya ga mold; idan aka yi amfani da lambar 3054 baƙin ƙarfe simintin ƙarfe kawai yana buƙatar a kashe harshen wuta a saman ƙirar, kuma babu ciwace-ciwacen mannewa da za su bayyana a saman ƙirar. Bugu da kari, ciminti carbide abun da ake sakawa za a iya amfani da a cikin m sassa na mold, wanda ke da kyau kwarai matsawa juriya, m lalacewa juriya da dogon m surface roughness da girma daidaito kula. Duk da haka, saboda batutuwan farashin, an rage amfani da shi wajen samarwa.

Surface aiki na aikin sashi na mold

The surface ingancin da bakin karfe zane mutu ne sosai m. Ƙarƙashin ƙasa na iya rage juriya da haɓaka juriya. Bayan mutuwar zane yana ƙasa, yana da mahimmanci don kawar da alamun cnc machining. The nika da polishing matakai sau da yawa ana watsi da mold masana'antu. Ya kamata a nuna. A cikin dukan mold aiwatar da aiki, polishing aiki ya kamata lissafin kashi daya bisa uku, saboda bayyanar ingancin kayayyakin bakin karfe ya dogara da babban har a kan mold polishing fasahar. A surface roughness na mold an rage, da kuma yawan nika na mold aka correspondingly rage, da kuma sabis rai na mold aka correspondingly inganta. Idan saman mold ba a goge shi sosai ba, kuma takardar bakin karfe ta zurfafa, yana da sauƙi don haifar da halayen ciwace-ciwacen mannewa, kuma samfurin da aka zana zai sami ɓarna mai tsanani. Koyaya, goge karce akan samfurin yana ɗaukar lokaci kuma baya tasiri. Saboda haka, ya kamata mu yi aiki tuƙuru a cikin mold polishing tsari. Sai kawai a lokacin da mold surface machining daidaito da aka inganta za a iya rage scratches na samfur, da mold gyara rayuwa za a iya ƙwarai inganta.

A cikin 'yan shekarun nan, sabbin fasahohin goge goge da kayan aikin goge goge sun bayyana a kasar Sin. Sabbin fasahohi da kayan aiki irin su ultrasonic, electrolytic polishing, abrasive jet, extrusion honing, da dai sauransu an ɓullo da su. Dangane da bayanin, an gudanar da gwajin polishing na electrochemical akan gyare-gyaren CrWMo, 3Cr12W8V, da Cr12, wanda ya tabbatar da cewa gogewar na iya canza yanayin ƙurawar ƙura daga asalin Ra3.2-Ra1.6 a cikin 5 kawai. - Minti 10. A kan wannan, an rage shi zuwa Ra0.4-RaO.2. A lokaci guda, electrochemical polishing kuma iya ƙara da surface taurin don inganta lalacewa juriya. Ga wani misali, na'urar polishing na ultrasonic za a iya amfani da shi don gyaran gyare-gyare na nitrocarburized rami, wanda zai iya kauce wa gazawar polishing na hannu wanda ke lalata fim din nitride cikin sauƙi. Ya kamata mu yi amfani da rayayye da kuma taƙaita sabuwar fasahar goge goge.

Tsarin lubrication

Daga sifofin zane na bakin karfe, ana iya ganin cewa samuwar ciwace-ciwacen mannewa ne saboda hulɗar kai tsaye tsakanin karfe da mold. Wannan gaskiya ce a ka'idar da ba za a iya jayayya ba. Sabili da haka, babban batu na zabar mai mai ko mai sutura yana cikin karfe zurfin zane tsari. Fim ɗin lubricating na tsakiya baya fashe daga farkon zuwa ƙarshe kuma yana taka rawa na lubrication. "Anti-danko da rage gogayya" shine ainihin wurin farawa don zabar man shafawa.

Gabaɗaya, ƙara wani kaso na matsananciyar ƙarar matsa lamba ga mai mai ko amfani da ingantaccen man shafawa na iya samun kyakkyawan sakamako. Wannan yana da mahimmanci don haɓaka ikon mai mai a saman ƙarfe don samar da sulfur, phosphorus, da mahadi na chlorine waɗanda ke yin maganin sinadarai tare da saman ƙarfe a yanayin zafi mai zafi don samar da ƙarfe sulfide, ƙarfe chloride, da sauransu don haɓaka ƙarfin ƙarfe. fim din mai da haɓaka ƙarfin adsorption , Kyakkyawan lubrication na mold da samfurin samfurin. Ana cika madaidaitan man shafawa a cikin ƙananan ramuka akan saman ƙarfe don rage busassun wuraren tuntuɓar juna. Bugu da kari, m man shafawa suna da babban kwanciyar hankali, kuma za su iya taka wani lubricating sakamako a high yanayin zafi, kuma ba su yiwuwa ga mold adhesion. Yawancin lokaci a cikin samarwa bisa ga matakin nakasar samfur da zaɓi na ainihin halin da ake ciki da dabara (za'a iya samun dabarar a cikin littafin hatimi mai dacewa).

Bugu da ƙari, ana iya amfani da mai, mai ma'adinai, man shafawa, man shafawa, sabulu don samar da man shafawa, kuma suna da tasiri mai kyau akan bakin karfe mai zurfi. Hakanan ana iya amfani da man ma'adinai mai ɗauke da emulsion mai narkewa da ruwa ko kuma an diluted da mai don zane marar zurfi. Ƙara graphite zuwa mai mai na iya taka rawa wajen hana mannewa, amma yana da wahala a tsaftace bayan ƙara graphite. Idan ka zaɓi 3054 gami da simintin gyare-gyaren ƙarfe don yin gyare-gyare, babban mai mai ya fi kyau.

Bisa ga bayanan, za a iya bi da kayan takarda tare da wanka na gishiri don samun nau'in nau'in nau'in nau'i mai laushi (kamar jan karfe, zinc, gubar, da dai sauransu) a kan saman, kuma mold ba zai faru ba yayin aikin zane mai zurfi. . Bugu da ƙari, a cikin 'yan shekarun nan, wani fim ɗin lubricating na polymer tare da polyvinyl butyral kamar yadda babban jiki ya kasance. Ana kula da farfajiyar sararin samaniya don samun nau'in fim din lubricating na kwayoyin halitta, wanda zai iya lalacewa tare da kayan aikin takarda, wanda ba wai kawai ya guje wa mold Ba tare da haɗin kai tsaye tare da kayan aiki ba yana hana m mold kuma yana tabbatar da ingancin samfurin. Bugu da ƙari, raguwa tsakanin mold da takarda abu yana raguwa sosai, kuma yana da sakamako mai kyau na lubrication. Gwajin ya nuna cewa tasirin yana da kyau.

Shiga wannan labarin : Matsalolin gama gari Da Magani Ga Bakin Karfe Zurfin Zane Mold

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan