Nazarin Halaye Na Micro-Profiles Surface Machining

Binciken Halayen Machining Surface Micro-profiles

|

Ɗaukar samfurin ma'auni na ma'auni a matsayin abu, ana nazarin bambanci a cikin nau'i na nau'i na nau'i daban-daban na inji, ana nazarin halayen yanayin da aka samu ta hanyar machining daban-daban, kuma ana lura da yanayin da aka samu ta hanyar machining daban-daban. . . Sakamako ya nuna cewa: yanayin yanayin yanayin yanayi da ƙarancin ƙima na daidaitattun samfuran da aka samu ta hanyoyin mashin ɗin daban-daban sun bambanta da digiri daban-daban; da yawa daga cikin kyakkyawan tsari da kuma kololuwar bayanin martaba na daban-daban machining surface morphologies sun bambanta, wanda ya bambanta da wancan. Tsarin sarrafawa yana da alaƙa; Tsarin yanayin halittar saman na daban-daban roughness da aka samu ta irin nau'in mashin ɗin yana da kamanceceniya da kansa, kuma yana da halaye na dabi'a da halaye na tsari, waɗanda za a iya amfani da su don bambance hanyoyin injinan daban-daban. |

Tare da haɓakar haɓakar kimiyya da fasaha cikin sauri, buƙatun ingancin samfuran injuna daban-daban suna ƙaruwa da girma. Tsarin ilimin halittar jiki da tsarin ba wai kawai yana shafar kaddarorin inji na tsarin injina kamar gogayya da lalacewa, taurin lamba, ƙarfin gajiya, kaddarorin mating, daidaiton watsawa, aikin rufewa, da daidaiton ganowa, amma kuma kai tsaye yana shafar aikin, rayuwa da bayyanar. na inji.

A cikin ƙananan na'urori, ƙananan ƙananan ƙwayoyin cuta kuma suna da alaƙa da haɗin kai, lalacewa, lubrication da sauran abubuwan haɗin gwiwa.

Halin yanayin sararin samaniya (geometry da rubutu, da dai sauransu) na injin da aka yi amfani da shi ya dogara da matsayi na juna tsakanin kayan aiki da kayan aiki a lokacin motsi na yanke. Ba wai kawai yana da alaƙa da ƙayyadaddun hanyar yankewa da yanayin yanke ba, har ma da haɓakar tsarin kayan aikin injin Halayen, kayan aikin yankan da kayan aiki da halayen injina na kayan aikin suna da alaƙa [4]. Nazarin halaye da ka'idojin ciki na micro-morphology na sassa daban-daban na injina yana da mahimmancin ƙima don zurfin fahimtar hanyoyin injinan hanyoyin injinan daban-daban da bambance-bambancen su, kuma yana ba da tushe na fasaha don injina.

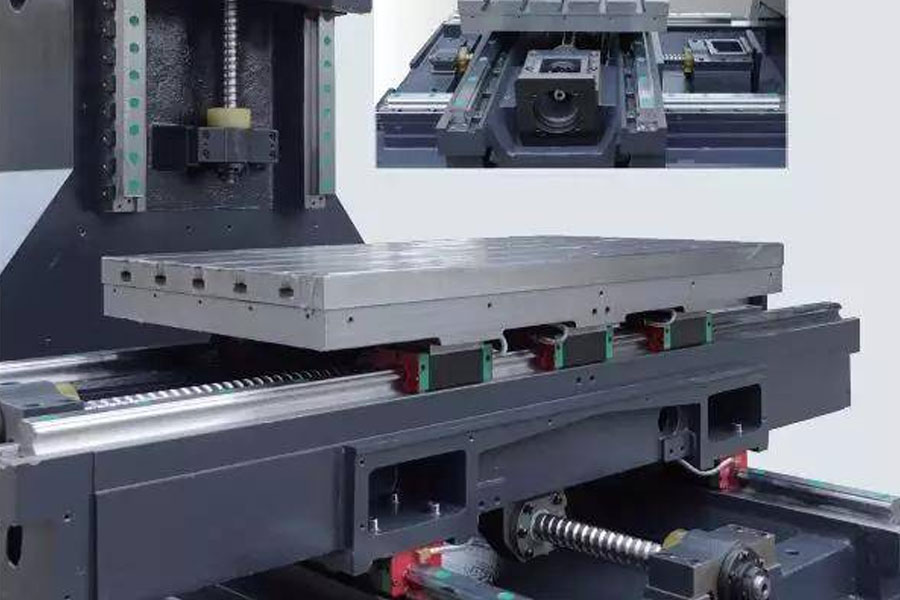

Marubucin wannan takarda ya ɗauki machining (juyawa, tsarawa, milling ƙare, lebur milling, m, lebur niƙa) misali tubalan a matsayin abu, nazarin bambanci a cikin surface roughness samu ta daban-daban machining hanyoyin, da kuma nazarin daban-daban machining hanyoyin da halaye. an samu yanayin yanayin yanayin da kuma tsarin, kuma an lura da ka'idar tsarin halittar saman tare da nau'i daban-daban da aka samu ta hanyar injin guda ɗaya. Don haka, ku fahimci halayen hanyoyin injinan daban-daban da bambance-bambancen su.

1 Bambance-bambance a cikin rashin ƙarfi na saman na'urori daban-daban

Kayan aikin shimfidar wuri na iya auna nau'ikan sigogi 28 na saman saman. Zaɓi tsayin samfurin don zama 5mm kuma tazarar samfurin don zama 1.25 μm don auna sigogin saman saman saman na'urar daidaitaccen samfurin toshe. Matsakaicin ƙimar bayanin martabar da aka saba amfani da shi an zaɓi Ra azaman ma'aunin ƙimar ƙima don tantance bambanci a cikin tarkacen saman saman na'ura daban-daban. Hanyoyi daban-daban na machining suna samun darajar Ra na nau'i-nau'i na ma'auni daban-daban (ɗaukar matsakaicin ma'auni na 3), da kuma bambanci tsakanin ma'auni na ma'auni da ƙima na toshe samfurin.

- (1) Akwai kurakurai daban-daban a cikin ƙididdige ƙimar ƙaƙƙarfan ƙima na shimfidar wuri na ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun samfuran da aka samu ta hanyoyin mashin ɗin daban-daban. Alal misali, don hanyoyin sarrafawa daban-daban, ma'auni na ma'auni da bambance-bambance na farfajiya na daidaitattun samfurin samfurin tare da rashin ƙarfi na Ra 0.8 μm sun bambanta. Ƙarami zuwa babba), ƙimar ƙaƙƙarfan ƙima ya fi ƙanƙanta fiye da ƙimar ƙaƙƙarfan samfurin toshe don tsari na ban sha'awa, milling na ƙarshe, da niƙa mai lebur (daga ƙarami zuwa babba).

- (2) Kuskuren da ke tsakanin ma'auni mai ƙima na farfajiya tare da nau'i daban-daban da aka samu ta hanyar mashigin guda ɗaya da ƙimar ƙimar daidaitaccen samfurin kuma ya bambanta. Misali, don jujjuya aiki, ƙarancin saman daidaitattun samfuran da aka samu shine Ra 0.8 μm, 1.6 μm, 3.2 μm, 6.3 μm, kuma canjin canjin kuskuren da ke tsakanin ma’aunin ma’aunin su ya bambanta, kuma ƙimar roughness shine Ra0. Ma'auni na roughness na 8μm, 1.6μm da 6.3μm sun fi girma fiye da ƙayyadaddun ƙayyadaddun toshe samfurin; lokacin da roughness darajar ne Ra3.2 μm, ma'auni roughness darajar ne karami fiye da roughness darajar da misali toshe samfurin. Duk da haka, kurakuran da aka auna na misalan ma'auni guda huɗu waɗanda aka sarrafa ta hanyar milling na ƙarshe duk ba su da kyau, wato, ma'auni na ƙazanta duk sun yi ƙasa da ƙaƙƙarfan ƙimar daidaitattun samfuran.

Ana samun sifofin micro-morphology na saman injinan daban-daban ta hanyar amfani da hanyoyi daban-daban na machining (juyawa, m, milling na ƙarshe, tsarawa, milling, lebur niƙa) don daidaitattun samfuran tare da rashin ƙarfi iri ɗaya (Ra0.8 μm) Akwai babban bambanci. a cikin ilimin halittar jiki

-

(1) The yawa na microstructure na daban-daban machined surface morphologies ne daban-daban, daga low zuwa high, su ne lebur milling, planing, karshen milling, lebur nika, m, da kuma juya.

-

(2) Halin halittar saman da tsarin sassa daban-daban na inji suna da wasu kamanceceniya. Misali, juyawa da ban sha'awa sune tsarin bazara; planing da lebur milling su ne kalaman tsarin; karshen niƙa da lebur nika ne serrated Tsarin.

- (3) The ganiya canji amplitude na surface profile ne lebur nika, juya, planing, karshen milling, m, da lebur milling a saukowa domin, wanda ke da alaka da sarrafa inji na daban-daban machining hanyoyin.

Ƙimar ƙarancin yanayin aikin niƙa yana da girma, kuma manyan abubuwan da ke tasiri sune:

-

① A yankan gefen (abrasive hatsi) na nika dabaran ba ci gaba da mike line, wanda zai bar wani saura yanki a kan workpiece bayan nika.

-

② A cikin nika tsari, da filastik nakasawa na karfe a saman na workpiece sa da yankan zafin jiki ci gaba da tashi, wanda accelerates lalacewa daga nika dabaran da kuma haifar da tsanani extrusion;

- ③Zaɓin sigogi kamar adadin niƙa, ruwa mai niƙa da izinin niƙa suna da wani tasiri a kan ƙarancin aikin aikin.

3 Halayen yanayin yanayin sama na hanyar sarrafawa iri ɗaya tare da ƙazanta daban-daban

The surface profile kwana na daidaitaccen samfurin toshe tare da daban-daban roughness (Ra0.8μm, 1.6μm, 3.2μm) aka samu ta lebur milling inji. Tsawon samfurin shine 3.75mm, tazarar samfurin shine 1.25μm, kuma adadin maki shine maki 3,000. .

-

(1) The surface profile tare da roughness na Ra 0.8 μm, 1.6 μm, 3.2 μm samu ta lebur milling inji yana da irin wannan wavy tsarin, wanda ya nuna cewa surface topography tsarin da daban-daban roughness samu ta hanyar machining hanya yana da kamance, kuma yana da halaye na dabi'a da tsarin tsari, wanda kuma za'a iya amfani dashi don bambance hanyoyin injina daban-daban.

-

(2) Ƙimar kololuwar bayanin martabar milling ɗin lebur yana ƙaruwa tare da haɓaka ƙimar ƙaƙƙarfan ƙima, wanda ya yi daidai da ma'aunin ƙimar Ra na matsakaicin tsayin bayanin martabar saman.

- (3) Girman tsarin tsarin micro-topography yana raguwa tare da karuwar rashin ƙarfi, kuma nisa tsakanin kololuwa yana ƙaruwa.

Kammalallen 4

-

(1) Akwai kurakurai na nau'ikan digiri daban-daban a cikin yanayin yanayin yanayin ƙaƙƙarfan dabi'u na ƙayyadaddun ƙayyadaddun ƙayyadaddun samfuran samfuran da aka samu ta hanyar injina daban-daban.

-

(2) Lokacin amfani da hanyar injin guda ɗaya don samun saman tare da nau'i daban-daban, kuskuren da ke tsakanin ƙimar ƙima da ƙima na daidaitaccen samfurin shima ya bambanta.

-

(3) Daban-daban na inji mai kwakwalwa ilimin halittar jiki, kyakkyawan tsari mai yawa da tsayin bayanin martaba duk sun bambanta, wanda ke da alaƙa da tsarin sarrafawa.

-

(4) Halittar yanayi da tsarin da aka samu ta hanyoyin mashina daban-daban suna da wani ma'auni na kamanni. Misali, juyawa da ban sha'awa sune tsarin bazara; planing da lebur milling su ne kalaman tsarin; karshen niƙa da lebur nika ne serrated Tsarin.

- (5) Siffar yanayin yanayin sararin samaniya da tsarin nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'i nau'i nau'i nau'i na nau'i-nau'i-nau'i-nau'i-nau'i-nau'i-nau'i-nau'i) suna da nau'i na nau'i-nau'i-nau'i-nau'i-nau'i-nau'i-nau'i-nau'i-nau'i-nau'i wanda za a iya amfani da su don bambance daban-daban hanyoyin inji.

Shiga wannan labarin : Nazarin Halaye Na Micro-Profiles Surface Machining

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan