Nazarin Ƙalubalen da ke cikin Grey Cast Cast Iron

Nazarin Ƙalubalen da ke cikin Grey Cast Cast Iron

|

Don magance matsalolin machining na simintin ƙarfe mai launin toka a cikin kamfani, an yi nazarin abubuwan da aka gyara da kaddarorin alade da simintin gyare-gyare ta hanyar microscope na gani, microscope na lantarki, taurin Brinell, taurin micro Vickers da ƙididdigar bakan. Sakamakon ya nuna cewa abun ciki na S da P na 26 # baƙin ƙarfe na alade ya kasance sama da babban gefen, abun ciki na Si na 22 # baƙin ƙarfe alade yana da ƙasa, don haka abubuwan sinadaran ba su gamsu da ka'idoji ba. Madaidaicin carbon ɗin simintin gyare-gyare shine 4.36%, wanda ke mallakar babban simintin carbon daidai. Matsakaicin Si da C shine 0.46, wanda ke kan ƙananan gefen. Abubuwan da ke cikin Si da Mn a cikin simintin gyare-gyare ba su da yawa, ban da abun ciki na Cr yana da girma, wanda ya isa ya haifar da yanayi mai sanyi, akwai nau'in V a cikin mafi yawan simintin. microstructure na simintin gyaran kafa shine ferrite, pearlite, graphite da carbide. Wani bangare na carbide ya ƙunshi Cr, V da sauran abubuwan da ke haifar da micro-alloying, kuma ƙananan taurin ya wuce 1 100 HV, wanda shine babban dalilin sarrafa injin da wahala. Saboda haka, don inganta machining c apacity, da farko, abun ciki na V da Cr bai kamata ya wuce misali ba. Na biyu, abin da ke cikin Si ya kamata a ƙara kuma ya kamata a fara zaɓar ƙarawa a cikin inoculation. Don buƙatun simintin gyare-gyare, ana iya bazuwar carbide ta hanyar graphitizing annealing. |

Farin sasanninta na simintin ƙarfe mai launin toka mai bakin bango lahani ne gama gari a cikin simintin gyaran kafa [1-4]. Gabaɗaya, ƙananan simintin gyare-gyare suna da siraran bango kuma ana jefa su cikin koren yashi. Ko da yake sinadarai na narkakkar baƙin ƙarfe sun cancanta, saboda tasirin kaurin bangon simintin da kuma zafin zafin na simintin, sassa masu kauri da bakin ciki na simintin guda ɗaya. Duka ciki da waje na iya samun ƙungiya ta daban. Musamman kusurwoyin simintin gyare-gyaren suna da saurin kamuwa da fararen baki, wanda ke haifar da matsaloli a cikin injina, wanda ke haifar da abin da ake kira "kayan abu mai wuya". Yawancin sassan ƙarfen simintin simintin gyare-gyaren launin toka "masu wuya" suna faruwa a cikin ɓangaren ƙaƙƙarfan ɓangaren. Irin su: gefuna da sasanninta, tsagi, filaye masu kama da juna, filaye, da sauransu. Taurin kayan yana da alaƙa da yanayin farin baki. Nufin matsalolin machining mai wahala a cikin ainihin samar da simintin gyare-gyare na wani kamfani, wannan takarda tana gudanar da bincike mai tsauri, tana nazarin abubuwan da ke haifar da "kayan wuya", kuma yana ba da shawarar mafita masu dacewa.

1 Kayan gwaji da hanyoyin

Simintin simintin alade 22#, 26# da na'ura mai lamba 0# an yi samfurin a wurin. Samfurori ta hanyar yankan waya an yi bi da bi, kuma an gudanar da lura da kyallen takarda da na'urar dubawa. Chemical akan simintin ƙarfe da simintin gyare-gyare

Gwajin haɗe-haɗe don keɓance tasirin abubuwan ganowa akan aikin sarrafa simintin gyare-gyare. An yi samfurin simintin gyare-gyaren don kallon ƙarfe a cikin ZEISS na gani da na'urar duba microscopes, HBS-3000 dijital taurin ƙarfin gwajin dijital da HTM-1000TM micro hardness tester an yi amfani da su don gwajin taurin. Abubuwan sinadaran ƙarfe na alade da simintin gyare-gyare an nuna su a cikin Table 1.

| C | Si | Mn | P | S | W | Te | Bi | Cr | V | Ce | B | Mo | |||

| 0 # 3.73 | 1.75 | 0.17 | 0.15 | 0.12 | ≤0.01 | 5 | 5 | 0.11 | 0.027 | 0.01 | 0.004 | 4 | ≤0.01 | ||

| 22 # 4.08 | 1.86 | 0.055 | 0.07 | 0.02 | ≤0.01 | 5 | 5 | ≤0.010 | ≤0.010 | 0.01 | 0.002 | 2 | ≤0.01 | ||

| 26 # 3.38 | 2.51 | 0.17 | 0.45 | 0.095 | ≤0.01 | 5 | 5 | 0.023 | 0.044 | 0.01 | 0.008 | 9 | ≤0.01 |

2.1 Binciken abubuwan da ke tattare da sinadarai

Lokacin da carbon simintin ƙarfe na simintin toka ya kasance a cikin nau'in carbides, yana ƙara haɓakar fata, wanda ke sa yin aiki da wahala kuma yana haifar da abin da ake kira "hard material" matsalar. Don haka, ƙarfen simintin launin toka ya kamata ya rage girman farar fata, ta yadda carbon ɗin ya kasance a cikin sigar graphite. Abubuwa daban-daban suna da tasiri daban-daban akan tsarin graphitization, da wasu duwatsu masu hanzariInking, wasu suna rage graphitization. Gabaɗaya magana, yawancin abubuwan da za su iya raunana ƙarfin haɗin gwiwa tsakanin ƙarfe da carbon atom da haɓaka ikon rarraba kai na ƙwayoyin ƙarfe na iya haɓaka graphitization na simintin ƙarfe; in ba haka ba, zai hana graphitization na simintin ƙarfe, wato, ƙara halin farin baki. . Don gwajin simintin ƙarfe

Ingancin baƙin ƙarfe na alade da kawar da tasirin abubuwan da aka gano akan farar simintin gyare-gyare. An gwada abubuwa biyar da abubuwan farar fata na yau da kullun na albarkatun da simintin gyare-gyare. An gwada kowane samfurin don abubuwa 13. An gwada batches 39 na ƙarfe na alade da simintin gyare-gyare. Ana nuna abun da ke tattare da sinadarai a cikin Table 1.

Simintin simintin ƙarfe na ƙarfe na alade na kasar Sin (GB/T 718-2005) [5], a cikin ma'auni, abun cikin Si na 22 # baƙin ƙarfe na alade shine 2.00% ~ 2.40%, kuma abun cikin Si na 26 # baƙin ƙarfe alade shine 2.40% ~ 2.80%. Dangane da Table 2, gwajin alade na kamfani 22 # da 26 # ya nuna cewa abun ciki na Si na 22 # baƙin ƙarfe na alade shine 1.86, wanda bai dace da ƙarancin ƙa'idar ba.

Ya dace da ma'auni, kuma abun ciki na Mn shima kadan ne. 26# ƙarfen alade P da S abun ciki yayi yawa sosai, abun cikin P ya kai matakin 5, abun cikin S ya wuce ma'auni, kuma ya ƙunshi adadin adadin Cr. Gwajin gwajin da aka yi na yin 0# ya nuna cewa abun cikin Cr ne kawai na abubuwan farin jini ya kai ga yanayin farin ciki, kuma abubuwan da ke cikin sauran abubuwan gano ba su kai mafi ƙarancin abin da ke haifar da farar fata ba, don haka tasirin ba shi da komai. Idan aka kwatanta da zaɓi na abubuwa biyar a cikin "Littafin Lissafin Casing" [6], za a iya ganin cewa abubuwan da ke cikin simintin gyare-gyare na carbon a cikin wannan binciken yana da girma sosai, abin da ke cikin Si yana da ƙanƙanta, kuma abun cikin Mn yana da ɗan ƙaranci. .

2.2 Gwajin taurin

A cikin HBS-3000 dijital nuni Brinell hardness tester, gwajin shine 1875 N, diamita na indenter shine 2.5 mm, kuma taurin gwaje-gwajen 5 an nuna shi a cikin Tebu 2. An yi masa alama da microhardness. Ana nuna sakamakon a cikin Table 3. Saboda haka, kodayake matsakaicin matsakaicin macroscopic na matrix yana da ƙasa sosai, kawai taurin Brinell yana kusan 145 HB, taurin yankinsa yana da girma sosai, yana kaiwa ga taurin Vickers na kimanin 1 000 HV. . Ƙananan ramin, mafi girma da taurin. Bisa ga wallafe-wallafen, taurin phosphorus eutectic shine 500 ~ 700 HV, ledeburite ≤ 800 HV, da carbide> 900 HV.

Sabili da haka, sakamakon binciken taurin ya nuna cewa yankin fari yana da wuya kuma yana da karyewar siminti carbide, wanda a zahiri ya keɓance eutectic na phosphorus, wanda shine babban dalilin kayan wuya. Don ƙayyade ainihin abin da ke cikin wannan carbide, ana buƙatar nazarin bakan makamashi.

2.3 Binciken bakan makamashi

An nuna girman girman yanki na fata na gani a cikin siffa 2 da Fig. 3. An kwatanta shi ta hanyar rarraba ramukan ramuka a cikin matrix da halayyar eutectic. Saboda haka, nazarin makamashi na wannan yanki ya nuna cewa abubuwan da ke cikin yankin da aka rage sune Fe, P da C element, don haka an yi la'akari da shi a matsayin Fe3 (C, P), ana adana P element.

Warewa. Rukunin P a cikin ɓangaren da aka dawo ya fi girma, ba samfurin eutectic ba, amma rami da aka kafa ta hanyar ƙarfafawa ta ƙarshe da raguwa. Hoto 4 Sakamakon bincike na bakan makamashi ya nuna cewa ban da abubuwan Fe, P da C, yankin farar fata ya ƙunshi Cr da V, suna samar da alloy carbides, waɗanda suka fi wuya da wuya.

Take yankan.

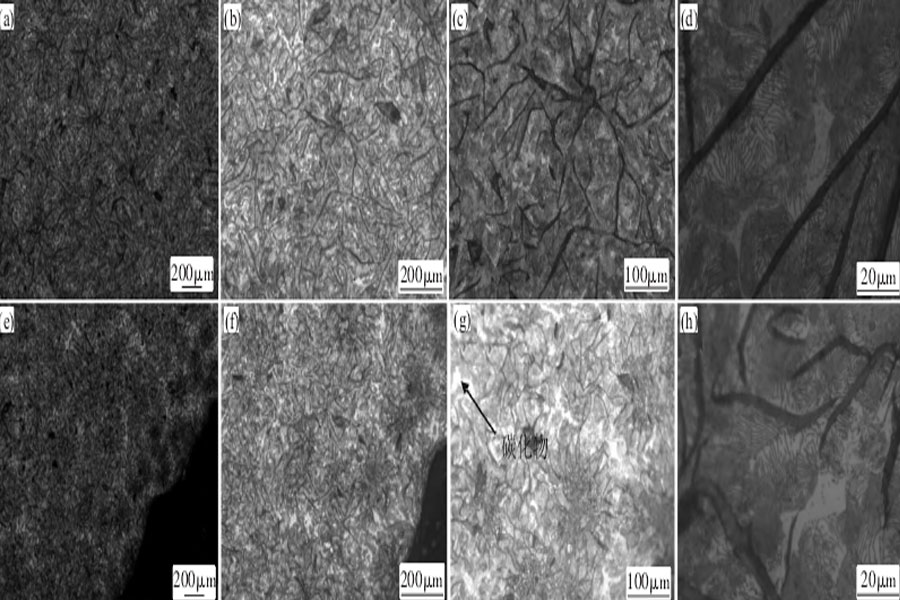

2.4 Binciken ƙungiyoyi

Hoton na gani yana nuna tsarin ƙarfe na simintin gyare-gyaren da aka yi ta hanyar etching tare da barasa na nitric acid 4%, kamar yadda aka nuna a cikin hoto na 5. Daga cikinsu, a, b, c, da d sune ainihin tsarin simintin, da e, f, g, da h sune tsarin gefen simintin. a, b, c, d da e, f, g, h sun dace da hotuna 50, 100, 200, da sau 1,000. Hoton nama da aka zana ana nuna shi a hoto na 6, kuma kibiya tana nuni zuwa ga farin yanki a cikin hoton kyallen kyallen da ya dace, wanda shine carbide. Yankunan farin toshe sune carbides, flakes sune graphite, kuma wuraren launin toka sune pearlite. Ana iya ganin cewa tsarin metallographic shine ferrite + pearlite + graphite + carbide, tsarin pitted. Farin gefuna a fili ya fi na zuciya tsanani. Idan aka kwatanta da GB/T7216-2009, ana iya ganin cewa [7], ƙwayar zuciya ita ce farkon.

Nau'in graphite mai ɗanyen tauraro mai siffa yana da tsawon kusan μm 150 kuma faɗin kusan μm 5. Wannan yana samuwa ta babban narkakken ƙarfe na carbon a ƙarƙashin in mun gwada da manyan yanayin sanyi. Tsarin Layer na gefen yana da kyau mai lanƙwasa graphite wanda aka tattara a cikin nau'in graphite mai kama da chrysanthemum. Tsawon yana kusan μm 100 kuma faɗinsa shine 3 μm. Ƙayyade adadin carbide

Adadin carbide a cikin nama na zuciya shine kusan 5%, yana kaiwa matakin 3. Adadin carbides a cikin nama na gefen shine kusan 10%, kaiwa matakin 4. Lokacin da carbon yana cikin nau'in graphite, ana iya amfani da graphite don lubrication a lokacin machining, kuma yankan yana da sauƙi. Lokacin da carbon ya kasance a cikin nau'i na carbide (Fe3C), saboda Fe3C cementite yana da wuya kuma yana raguwa, injin yana da wahala, musamman ma idan ya ƙunshi sauran abubuwan da aka haɗa (kamar Cr), siminti na alloy ((Fe, M) 3C) Wannan fili shine. da wuya da wuya a yanke, kuma abin da ake kira "hard material" yana faruwa a lokacin injina [8]. Saboda haka, a cikin aikin simintin gyaran gyare-gyare na sassa na ƙarfe mai launin toka, wajibi ne a rage adadin carbon don kauce wa bayyanar carbides, kuma a dauki wasu matakai don inganta aikin graphitization na carbon idan ya cancanta.

3 Nazari da tattaunawa

Babban abubuwan da ke shafar aikin injin na simintin gyare-gyare sune sinadarai na simintin ƙarfe da ƙarfin sanyaya ƙarfi. Abubuwan da ke cikin carbon da abun ciki na siliki a cikin sinadarai na simintin ƙarfe sune mahimman abubuwan sarrafawa guda biyu mafi mahimmanci. Yawan sanyaya simintin gyaran kafa ya dogara ne akan kaurin bangon simintin. Lokacin da abun ciki na carbon da silicon a cikin simintin ƙarfe ya kasance akai-akai, mafi ƙarancin bangon simintin, mafi girman yanayin simintin ƙarfe don yin fari. Lokacin da kaurin bangon simintin ya kasance akai-akai, yawan jimlar abun ciki na carbon da silicon a cikin simintin ƙarfe, mafi girman matakin graphitization na simintin ƙarfe.

Madaidaicin carbon ɗin da aka yi a cikin wannan binciken shine 4.36%, wanda shine babban simintin simintin ƙarfe; Si / C rabo shine 0.46, wanda yayi ƙasa. Ƙara daidai da carbon yana sa faifan graphite ya yi kauri, adadin yana ƙaruwa, ƙarfi da taurin suna raguwa. Ƙara Si/C na iya rage halin farin baki.

A cikin samar da baƙin ƙarfe mai launin toka, ana buƙatar la'akari da tasirin zafi da kuma tasirin gestation. Ƙara yawan zafin jiki na narkar da baƙin ƙarfe a cikin wani kewayon na iya sa gyare-gyaren graphite, tsarin matrix mafi kyau, ƙarfin ɗaure ya ƙaru, kuma taurin ya ragu. Wajibi ne a yi la'akari sosai da abin da ke tattare da cajin, kayan aikin narkewa, da abubuwan makamashi na abubuwan sinadaran. Maganin allurar ita ce ƙara inoculant a cikin narkakkar ƙarfe don canza yanayin ƙarfe na narkakken ƙarfe kafin narkakken ƙarfe ya shiga cikin rami na simintin gyare-gyare, kuma ƙara ƙarar ƙwayar da ba ta daɗe ba shine gyaran graphite. Ta haka inganta microstructure da aikin simintin ƙarfe. Inoculants na yau da kullun sun haɗa da ferrosilicon, siliki siliki da graphite. Haɗa samfuran mu da farashin samarwa, ana ba da shawarar yin amfani da ferrosilicon (75% silicon, adadin ƙari shine kusan 0.4% na nauyin narkakken ƙarfe). Na biyu, barium ferrosilicon da strontium ferrosilicon. Ferrosilicon inoculates sakamako mai sauri-aiki, yana kaiwa ga kololuwa a cikin mintuna 1.5, kuma yana raguwa zuwa yanayin da ba a ciki ba bayan mintuna 8 ~ 10, wanda zai iya rage ƙimar supercooling da yanayin farin baki, yana ƙara yawan gungun eutectic, samar da nau'in A-type. graphite, inganta daidaituwa na sashin, da haɓaka juriya. Ƙarfin juzu'i shine 10-20MPa. Rashin hasara: rashin juriya ga lalacewa. Idan ba a yi amfani da tsarin inoculation na marigayi ba, ba shi da kyau ga manyan bambance-bambancen kauri na bango da kuma tsawon lokacin zubawa.

Barium ferrosilicon yana da ƙarfi mai ƙarfi don ƙara yawan gungun eutectic da haɓaka daidaituwar sashe fiye da ferrosilicon. Ikon yin tsayayya da raguwa yana da ƙarfi, kuma ana iya kiyaye tasirin inoculation na minti 20. Ya dace da nau'o'i daban-daban na sassan simintin ƙarfe na launin toka, musamman dacewa da manyan sassa masu kauri da kuma yanayin samarwa tare da dogon lokacin zubowa.

Strontium ferrosilicon yana da 30% zuwa 50% mafi girman ikon rage farar fata fiye da ferrosilicon, kuma yana da ingantaccen sashe daidaitawa da ikon hana lalata fiye da ferrosilicon. A lokaci guda, ba ya ƙara yawan gungu na eutectic, yana da sauƙin narkewa, kuma yana da ƙarancin slag. Sassan katangar bango, musamman sassan da ke buƙatar raguwa da zubewa tare da manyan gungu na eutectic ba a so.

Abubuwan da Mn ke cikin simintin gyare-gyare a cikin wannan binciken ba su da yawa. Manganese da kansa wani sinadari ne wanda ke hana graphitization, amma manganese na iya rage tasirin sulfur mai ƙarfi. Saboda haka, a cikin iyakacin kashe tasirin sulfur, manganese a zahiri yana taka rawa wajen haɓaka graphitization. Ayyuka sun tabbatar da cewa karuwa a cikin abun ciki na manganese ba zai iya karuwa kawai da kuma tsaftace pearlite ba, amma ba cutarwa ba ne don shakata da kulawa da sulfur daidai. Don haka, ana ba da shawarar haɓaka abun ciki na Mn daidai.

Kammalallen 4

Babban dalilin da ke haifar da wahalar inji na simintin gyare-gyare a cikin wannan binciken shine bayyanar siminti carbides, musamman siminti carbides na gami da ke ɗauke da Cr, V da sauran abubuwan da ke haifar da matsalolin injin. Don inganta wannan matsala, ra'ayin farko shine rage ko kawar da carbide a cikin kungiyar. Canza abun da ke ciki na simintin gyare-gyare da daidaita tsarin samarwa hanyoyi ne masu tasiri. Haɗe tare da takamaiman yanayin samarwa na simintin gyare-gyare a cikin wannan binciken, an gabatar da shawarwarin samarwa masu zuwa:

- (1) Don ƙara abun ciki na silicon, zaɓi na farko shine ƙara inoculant kafin zubawa. Don ferrosilicon (75% silicon), barium ferrosilicon da strontium ferrosilicon kuma za a iya amfani da su bisa ga lokacin zubewa da tasirin kan-site. Ana ba da shawarar yin amfani da magungunan ƙwayoyin cuta (Si-Ba da RE-Si).

- (2) Ƙara abun ciki na manganese a cikin simintin gyare-gyare don daidaita tasirin farin bakin mai ƙarfi na sulfur.

- (3) Inganta ingancin ƙarfe na alade. 26#Abin baƙin ƙarfe P da S ya yi yawa.

- (4) Rage abun ciki na Cr a cikin simintin gyare-gyare. Babban abun ciki na Cr (> 0.1) a cikin simintin gyare-gyare na iya riga ya haifar da tasirin fari. Cr na iya ƙara taurin gaske kuma yana lalata aikin injin.

Shiga wannan labarin : Nazarin Ƙalubalen da ke cikin Grey Cast Cast Iron

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan