Zaɓin Lokaci na Jirgin Jirgin Jirgin Flange

Zaɓin Lokaci na Jirgin Jirgin Jirgin Flange

|

A cikin tsarin shigarwa na babban crane, flatness na crane flange zai canza. A al'ada yi shi ne na'ura crane flange jirgin bayan taro da waldi na crane tushe taro, don tabbatar da cewa flatness na crane flange hadu da bukatun na zane zane. Wannan takarda ta bayyana hanyar gwaji da tsarin aikin injin jirgin saman crane flange kafin taron tushe na crane da walda. Sakamakon gwajin ya nuna cewa, a ƙarƙashin yanayin tsarin ɗagawa da fasaha na walda tare da ingantaccen sarrafa nakasawa, ƙarancin flange na crane yana canzawa kadan bayan taro da waldawar ginin ginin crane, wanda zai iya biyan buƙatun zane zane. Yana adana lokaci don shigarwa na gaba na dandamali na rotary, yana rage sake zagayowar shigarwa na crane kuma yana guje wa haɗarin aminci da aikin hawan sama ya kawo, don haka yana kawo fa'idodin tattalin arziki mai kyau ga tashar jirgin ruwa. |

A cikin tsarin gaba ɗaya na jiragen ruwa masu aiki da yawa da dandamali daban-daban, ya zama al'ada don ba da manyan cranes. Gabaɗaya, babban kreen yana kunshe da tushe na crane, flange na crane (tare da silinda na kansa), dandamali mai kashe wuta, tripod, da bum. Daga cikin su, ginin crane yana da siffar zagaye na sama, wanda filin jirgin ruwa ke yin shi, sauran kuma ana saya. Flange na flange yana da mahimmancin fasaha na fasaha, zai

Yana shafar kai tsaye matakin haɗin gwiwa da yanayin pre-tightening tsakanin jiragen flange guda biyu masu haɗawa. Yadda za a sarrafa flatness na crane flange ba shi da kyau sosai, wanda shine mayar da hankali ga tsarin shigarwa na crane. Hanyar al'ada ita ce fara haɗawa da walƙiya tushe na crane da flange na crane a cikin abubuwan da ke ƙarƙashin jirgin (nan gaba ana magana da shi azaman taron ginin crane), sannan a haɗa tare da walda taron ginin crane zuwa crane, sannan a ƙarshe na'urar jirgin flange na crane. . Tun da machining na crane flange jirgin sama a kan jirgin aiki ne mai tsayin daka aiki, akwai hadarin aminci, da kuma machining lokaci ne mai tsawo, wanda rinjayar da crane sake zagayowar. A saboda wannan dalili, mun wuce gwajin gwajin kuma mun zaɓi abubuwan haɗin ginin crane don haɗawa da walda su a ƙarƙashin jirgin, sannan flange na crane yana lebur.

Yiwuwar machining saman.

2 Hanyar Gwaji

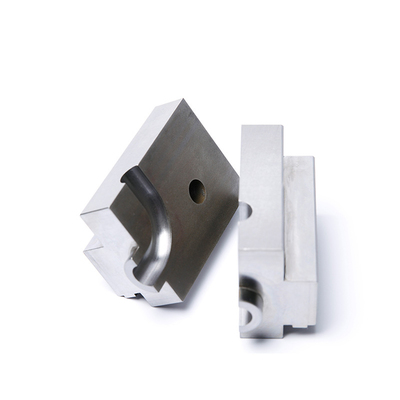

An gudanar da wannan gwajin ne a lokacin da ake girka na'urar dagawa mai lamba 350 a kan wani nau'in dandamali. The crane flange zane girma su ne: da flange zo da wani Silinda m diamita na 7 590 mm, a ka'idar kauri na 110 mm, wani m diamita na 7 910 mm, wani ciki diamita na 7 470 mm, da'irar diamita na cibiyar rami mai haɗawa 7 760 mm, da haɗin haɗin 150 * M60 mm iri ɗaya rarraba. Zane-zanen ƙirar yana buƙatar 1.5 mm don daidaitawar flange crane, kamar yadda aka nuna a hoto 1.Mun auna flatness na crane flange a wadannan biyar nodes:

- (1) Bayan flange crane ya zo;

- (2) Bayan an kammala taron ginin ginin crane;

- (3) Bayan da aka kammala waldi na crane tushe aka gyara;

- (4) Bayan da aka kammala taron na crane tushe taro gondolas;

- (5) Bayan da aka kammala walda na crane tushe sassa a kan jirgin da aka kammala.

Bincika ƙimar daɗaɗɗa da canjin yanayin kowane kumburi don tantance yuwuwar yin aikin injin jirgin saman crane flange bayan an haɗa ginin ginin crane.

3 Sakamakon gwaji da bincike

3.1 Bayan flange crane ya zo

An yanke shawarar da taron na musamman cewa flatness na crane flange kada ya zama fiye da 1.5 mm lokacin da manufacturer ya ba da; la'akari da nakasawa na canja wuri da hoisting, da flange kauri reserves 6 ~ 10 mm ga sakandare aiki.

Kafin flange crane ya zo, za a shirya tallafin kayan aikin daidaitacce a wurin da aka zaɓa. Akwai jimlar 8 kayan aiki goyon baya, wanda aka shirya a daidai sassa bisa ga kewaye da ƙananan bakin na crane flange Silinda; kuma ana auna ma'auni na goyon baya tare da jimlar tashar, kuma ana sarrafa ma'auni na goyon baya a cikin 2 mm ta hanyar daidaita tsayin goyon baya; flange na crane Bayan zuwan kaya, an sanya flange na crane a kan goyon bayan kayan aiki ta hanyar gantry crane na jirgin ruwa. A wannan lokacin, lebur ɗin da aka auna ta hanyar kayan haɓaka laser shine 3.99 mm. Wannan saboda ko da yake masana'anta suna aiwatar da flatness na crane flange zuwa cikin 1.5 mm, da flatness sabawa na flange ne in mun gwada da girma saboda da yawa dagawa da canja wuri. Babban karuwa.

3.2 Bayan an kammala taron ginin ginin crane

Ana shirya goyan bayan kayan aiki masu daidaitawa a wurin taron da aka zaɓa. Akwai goyan bayan kayan aiki guda 12, waɗanda aka shirya su daidai gwargwado bisa ga kewayen ƙananan bakin tushe na crane; Ana auna ma'auni na goyon baya tare da jimlar tashar, kuma ana sarrafa ma'auni na goyon baya a cikin 2 mm ta hanyar daidaita girman goyon baya; gindin crane daga ɗakin yashi na jirgin ruwa Bayan fitowa, kula da hankali don daidaita madaidaicin motar canja wuri don tabbatar da cewa wurin sanyawa na crane tushe ya dace da jagorancin bayan kaya; ɗaga tushen crane zuwa goyan bayan kayan aiki, sannan kuma rataya flange na crane zuwa tushe na crane bayan tsayawa na tsawon sa'o'i 8 An haɗu da ɓangaren sama tare da tushe na crane bisa ga buƙatun taro na zane, kuma an sanya shi tare da farantin lambar walda. . A wannan lokacin, flatness da aka auna ta hanyar ma'aunin matakin laser shine 3.38 mm. A wannan lokacin, an rage raguwar ɓacin rai na flange crane. Wannan shi ne saboda bayan da crane flange da aka hoisted zuwa babba bakin crane tushe, da goyon bayan batu yana ƙaruwa, wanda rage flatness sabawa.

3.3 Bayan waldi na crane tushe aka gyara da aka kammala

Game da cewa abu na crane flange ne EH36 da kuma kayan da crane tushe ne EH500.

A lokacin aikin walda, zafin interlayer, halin yanzu walda, ƙarfin lantarki da saurin walda yakamata a sarrafa su sosai. Kafin waldawa, preheat ɓangaren walda da kewaye sau 3 na kauri na farantin zuwa 120 ℃, kuma zafin jiki na interlayer shine ≥ 110 ℃; walda da aka welded da wani ko da adadin walda a lokaci guda, kuma kowane sashe na walda aka raba zuwa 600 ~ 1 000 mm, da kuma sashe aka ja baya. Ana yin walda; Bayan an gama waldawa kuma an sanyaya walda, girman flange na crane shine 5.42 mm auna tare da ma'aunin matakin laser. A wannan lokaci, da flatness sabawa na crane flange ƙara, saboda waldi hadin gwiwa ne 1 335 mm daga crane flange jirgin sama, da shrinkage na waldi kabu yana da mafi tasiri a kan flatness na crane flange; Bugu da kari, ana yin waldawar haɗin gwiwa. Tsarin ba cikakke ba ne, kuma ba a kula da zafin jiki tsakanin yadudduka na walda a ainihin lokacin, wanda ya haifar da karuwa a cikin karkacewar flange na crane.

Matsakaicin kauri na crane flange shine 110 mm, ainihin kayan da ke shigowa sune 120 mm, kuma akwai izinin injin na 10 mm, don haka izinin injin ya isa; da flatness na crane flange ne duka a lokacin da crane tushe taro da aka harhada da jirgin ne welded. Za a yi canje-canje, amma tun da ƙananan ɓangaren ginin ginin crane yana da 7 906 mm nesa da jirgin saman crane flange, flange flatness lalacewa ta hanyar waldi tare da hull ba ya canja da yawa. Dangane da bincike na sama, mun yi imanin cewa sarrafa nakasar dagawa shine mabuɗin. Muddin ana sarrafa nakasar ɗagawa yadda ya kamata, yana da yiwuwa a zaɓi yin injin jirgin saman crane ɗin a wannan lokacin.

Ana ƙididdige nauyin aikin haɓakawa bisa ga tsarin haɓakawa: jimlar nauyin abubuwan haɗin ginin crane shine 132.2 t, jimlar nauyin 2 # da 3 # na gantry crane shine 63.7 t; Tsaya jimlar nauyin 160 t (ban da nauyin gantry crane). An tsara lambar hoisting a wannan matsayi, kuma akwai saitin tushe mai ƙarfi na crane sama da lambar hawan. Ƙarfin yana aiki akan farantin ƙarfafa mai siffar zobe, wanda ba shi da ɗan tasiri a kan shimfidar flange na crane.

Yi amfani da saitin injunan niƙa da aka ƙarfafa waɗanda ke zuwa tare da ganga flange na crane don sarrafa jirgin saman flange. La'akari da cewa za a yi crane tushe aka gyara hoisting, hadawa da waldi aiki, da flange flatness ake bukata da za a sarrafa zuwa 0.80 A cikin mm; bayan aiki, shigar da alamar bugun kira akan injin niƙa

Ƙimar da aka auna shine 0.75 mm, wanda ya fi ƙasa da 1.5 mm da ake bukata ta zane; An auna kauri na flange tare da caliper, kuma mafi ƙarancin kauri shine 115.52 mm, wanda ya fi 110 mm da ake buƙata ta zane. Bayan da aka kammala machining na flange jirgin na crane, ba a cire ƙarfafa na asali Silinda jiki, da kuma wani sa na ƙarfafa goyon baya da aka kara 100 mm saukar daga ƙananan jirgin sama (kushin goyon baya da flange Silinda jiki ba su da. welded), da kuma ginin ginin crane Sassan tsakiya da na ƙasa har yanzu suna riƙe da sassa biyu na ƙarfafa wucin gadi; An rufe jirgin da aka gama crane flange da kyalle mai ƙarfi uku bayan shafa man shanu don hana ƙura da yazawar ruwan sama; Lokacin shigar da dandali na rotary a cikin mataki na gaba, kammala zane mai tabbatarwa uku sa'a daya a gaba Rushewa da aikin cire man shanu. Lambar hoisting da tsarin ƙarfafawa don haɓaka abubuwan tushe na crane.

3.4 Bayan taron na crane tushe taro a kan jirgin da aka kammala

Yi amfani da crane gantry 900t don ɗaga abubuwan haɗin ginin crane. Bincika hanyar shigarwa na haɗin ginin crane kafin hawan; An haɗa ginin ginin crane da saman ɗakin da ake gyarawa na jirgin ruwa kuma an daidaita shi, kuma ana yin walda mai kamewa bayan biyan buƙatun. Tsawon ƙuntataccen walƙiya ɗinka bai kamata ya zama ƙasa da 70 mm ba, kuma nisa ya zama 800 ~ 1 000 mm. Ƙaƙƙarfan walda ɗin ana walda shi daidai gwargwado ta madaidaicin adadin masu walda a lokaci guda; bayan taro da matsayi, da flatness na crane flange da aka auna tare da Laser matakin ma'auni. An auna jimlar maki 30, aya ɗaya a tazarar 12°. Bayanan ma'auni sun nuna cewa an ƙara ɗanɗano lebur ɗin flange na crane fiye da na sama da 0.75 mm bayan an haɗa ginin ginin crane akan crane, amma har yanzu ana iya sarrafawa.

3.5 Bayan walda na crane tushe aka gyara a kan jirgin da aka kammala

Bayan da crane tushe taro crane taro da aka kammala, da wadannan waldi matakan matakai don sarrafa nakasawa da aka tsara: bayan kowane symmetric waldi na 600 zuwa 1 000 mm welds, da flatness na crane flange surface an auna. Idan buƙatun sun cika, ci gaba da kammala waldi na sauran sassan kuma auna flatness na crane flange surface; idan ba a cika buƙatun ba, a dakatar da walda nan da nan, kuma ma'aikatan aikin za su yi nazari tare da tsara matakan da za su bi. Bayan da yawa ma'auni, da flatness na flange surface na crane ne a cikin bukatun na zane zane; Bayan an gama duk walda kuma an sanyaya walda, ana auna lebur ɗin flange na crane tare da ma'aunin matakin laser, kuma ana auna jimlar maki 30. Maki ɗaya kowane 12°. A auna bayanai ya nuna cewa bayan waldi na crane tushe taro da kuma hull da aka kammala, saboda waldi zafi shrinkage, da flatness na crane flange ne dan kadan ya karu, da kuma karshe darajar ne 1.16 mm, wanda ya gana da bukatun na zane zane.

Kammalallen 4

Gwaje-gwaje sun tabbatar da cewa a cikin tsarin shigarwa na manyan cranes, idan dai ana amfani da goyon bayan kayan aiki, tsarin hawan igiyar ruwa da tsarin walda don sarrafa nakasa yadda ya kamata, ana zabar sassan ginin crane da za a yi amfani da su bayan an haɗa kayan ginin crane da waldawa. karkashin jirgin. Yana yiwuwa. Zai iya adana lokaci don shigarwa na gaba na dandamali na rotary, rage sake zagayowar shigarwa na crane da kuma guje wa haɗarin aminci da ayyuka masu tsayi suka haifar, da kuma kawo fa'idodin tattalin arziki mai kyau ga tashar jirgin ruwa. Wannan gwaninta ya cancanci tunani da tunani ta wasu filayen jiragen ruwa.

Shiga wannan labarin : Zaɓin Lokaci na Jirgin Jirgin Jirgin Flange

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

Shagon PTJ CNC yana samar da sassa tare da kyawawan kayan aikin injiniya, daidaito da maimaitaccen ƙarfe da filastik. 5 axis CNC milling akwai.Ingirƙirar allo mai zafi mai zafi zangon kira injel sarrafawa,kayan masarauta,Geek Ascology kayan aiki,Katako 49 machining,Kayan aikin Hastelloy,Nitronic-60 aikin inji,Kayan aikin Hymu 80,Kayan aikin karfe, da sauransu. Ingantacce don aikace-aikacen sararin samaniya.Cibiyar CNC yana samar da sassa tare da kyawawan kayan injiniya, daidaito da maimaitawa daga ƙarfe da filastik. 3-axis & 5-axis CNC milling available.Mu yi dabaru tare da kai don samar da ayyuka mafi tsada don taimaka maka isa ga burinka, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan