Takaitaccen bayanin fasahar buga carbon 3D XNUMXD da aikace-aikacen sa a masana'antar sassan

2019-09-14

Takaitaccen bayanin Carbon fiber 3D bugu

| 3D buga carbon fiber shine na biyu bayan ana neman kayan ƙera masana'antu bayan ƙarfe. Saboda keɓaɓɓun abubuwan keɓaɓɓen fiber, kamar: nauyi, ƙarfi mai ƙarfi, haɓakar haɓakar lantarki, haɓakar haɓakar lalata, ɓangarorin da aka yi tare da fasahar dab'i na 3D galibi suna da madaidaicin daidaito da aiki mai kyau. |

Carbon fiber 3D bugu fasahar

▶ Laser sintering fasaharHalayen kayan aiki: Short fiber ƙarfafa nailan, PEEK, TPU da sauran kayan foda

Halayen tsari: Haɗa gajeriyar fiber carbon fiber da kayan nailan a cikin wani ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun tsari, kuma ku gane gyare-gyaren haɗin gwiwa ta hanyar yin amfani da Laser sintering.

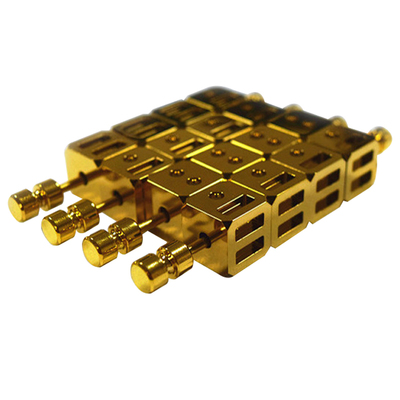

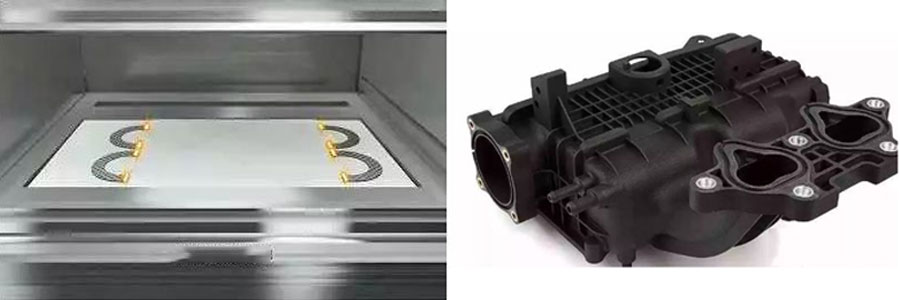

Laser sintered carbon fiber mota ci da yawa aikin samfur

▶ Multi-jet narkewa fasahar

Halayen kayan aiki: Short fiber ƙarfafa nailan, PEEK, TPU da sauran kayan foda

Halayen tsari: Ta hanyar dumama bututun fitila, sashin giciye yana tattara isasshen zafi don gane narkewar da ke faruwa a ƙarƙashin aikin mai ƙarfi.

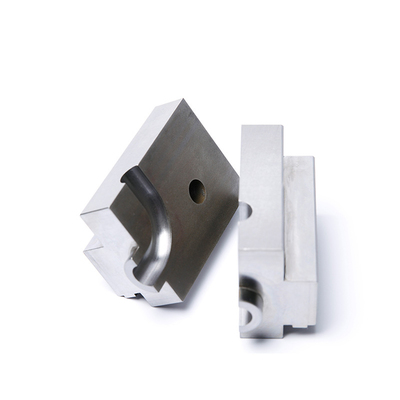

MJF fasaha bugu fiber ƙarfafa sassa

▶ Fasahar FDMHalayen kayan abu: dogon fiber ƙarfafa PLA, nailan, PEEK da sauran kayan waya

Halayen tsari: Dogon fiber yana cika cikin waya ta al'ada ta hanyar fasahar FDM don haɓaka tasirin.

FDM bugu na carbon fiber ƙarfafa PEEK reshe

Hanyar buguwar fiber carbon

▶ Yankakken carbon fiber cike da thermoplastic.Short-yanke carbon fiber cike da thermoplastics ana buga a kan daidaitaccen firintar FFF (FDM) mai kunshe da thermoplastic (PLA, ABS ko nailan) da aka ƙarfafa da ƴan yankakken igiyoyi, watau carbon fibers. A daya hannun, ci gaba da carbon fiber masana'antu ne na musamman bugu tsari cewa sanya ci gaba da carbon fiber daure zuwa daidaitattun FFF (FDM) thermoplastic substrates.

Filayen filaye masu cike da fiber na carbon da aka ƙera ana yin su ta hanyar amfani da fiber carbon, amma bambancin da ke tsakanin su yana da yawa. Fahimtar yadda kowace hanya ke aiki da ingantaccen aikace-aikacen sa zai taimaka muku yanke shawara game da abin da za ku yi a masana'anta ƙari.

3D bugu carbon fiber sanya da yankakken carbon fiber cika thermoplastic

Yanke zaruruwan carbon da aka yanke sune ainihin kayan ƙarfafa don daidaitaccen ma'aunin thermoplastics. Yana ba kamfanoni damar buga kayan da ba su da ƙarfi gabaɗaya a manyan matakan ƙarfi. Sannan ana haɗe kayan tare da thermoplastic kuma abin da ya haifar yana fitar da shi cikin spool don dabarar masana'antar filament narke (FFF).

Don haɗe-haɗe ta amfani da hanyar FFF, kayan shine cakuda yankakken zaruruwa (yawanci carbon fibers) da thermoplastics na al'ada (kamar nailan, ABS ko polylactic acid). Ko da yake tsarin FFF ya kasance iri ɗaya, yankakken zaruruwa suna ƙara ƙarfi da taurin ƙirar kuma suna haɓaka kwanciyar hankali, ƙarewar ƙasa da daidaito.

Wannan hanya ba koyaushe ba ta da aibi. Wasu yankakken filaye masu ƙarfafa filaye suna jaddada ƙarfi ta hanyar daidaita girman abin da ke tattare da zaruruwa. Wannan na iya haifar da mummunar tasiri ga ingancin aikin aikin gabaɗaya, rage ingancin saman da daidaiton sashi. Za a iya yin samfura da sassan amfani na ƙarshe daga yankakken fiber carbon saboda yana ba da ƙarfi da bayyanar da ake buƙata don gwaji na ciki ko abubuwan da ke fuskantar abokin ciniki.

Carbon fiber 3D bugu yana inganta tare da ci gaba da zaruruwa

Abubuwan ƙarfafa fiber fiber na ci gaba.

Ci gaba da carbon fiber shine ainihin fa'ida. Wannan ingantaccen bayani ne mai tsada don maye gurbin sassa na ƙarfe na gargajiya tare da 3D bugu masu haɗaɗɗiya saboda yana samun irin wannan ƙarfin ta amfani da juzu'in nauyi kawai. Ana iya amfani da shi don shigar da kayan a cikin thermoplastics ta amfani da fasahar kera filament ci gaba (CFF). Mai bugawa da ke amfani da wannan hanyar yana sanya filaye masu ƙarfi masu ƙarfi (misali, fiber carbon, fiberglass ko Kevlar) ta bututun bugu na biyu a cikin FFF extruded thermoplastic yayin bugu. Ƙarfafa zaruruwa suna samar da "kashin baya" na ɓangaren da aka buga, yana samar da tasiri mai ƙarfi, ƙarfi da ɗorewa.

Ci gaba da fiber na carbon ba kawai yana ƙara ƙarfi ba, har ma yana ba masu amfani da zaɓin ƙarfafawa a cikin wuraren da ake buƙatar ƙarfin ƙarfi. Saboda yanayin FFF na ainihin tsari, za ku iya zaɓar ginawa akan tsarin Layer-by-Layer.

A cikin kowane Layer, akwai hanyoyin haɓakawa guda biyu: ƙarfafa ƙarfafawa da ƙarfafa isotropic. Cika madaidaici yana ƙarfafa iyakokin waje na kowane Layer (na ciki da na waje) kuma ya faɗaɗa cikin ɓangaren tare da ƙayyadadden adadin zagayowar mai amfani. Cikawar isotropic yana samar da haɓakar haɗin gwiwa na unidirectional akan kowane Layer, kuma ana iya daidaita saƙar fiber carbon ta canza yanayin ƙarfafawa akan Layer. Waɗannan ingantattun dabarun ba da damar sararin samaniya, motoci da masana'antun masana'antu don haɗa kayan da aka haɗa cikin ayyukansu ta sabbin hanyoyi. Ana iya amfani da sassan da aka buga azaman kayan aiki da maras motsi (dukkan waɗannan suna buƙatar ci gaba da fiber carbon don yin kwatankwacin kaddarorin ƙarfe yadda ya kamata.), Kamar kayan aiki a ƙarshen hannu, ɓacin rai, da CMM maras motsi.

Aikace-aikace na carbon fiber kayan a cikin bangaren masana'antu

Nylon 12CF abu, wani sabon 3D buga carbon fiber abu dauke da har zuwa 35% carbon fiber, saboda haka yana da kyau a cikin kaddarorin kamar na karshe tensile ƙarfi na 76 MPa da tensile modulus na 7529 MPa. Tare da ƙarfin gyare-gyare na 142 MPa, ya isa ya maye gurbin karafa a aikace-aikace da yawa, isa ya maye gurbin karafa a aikace-aikace da yawa, yana sa ya dace da motoci, sararin samaniya da sauran masana'antu. Ana amfani da wannan fiber na carbon fiber ƙarfafa thermoplastic don samar da samfurori masu girma waɗanda za su iya jure wa gwaji mai tsauri na sassan samarwa yayin tabbatar da ƙira don saduwa da buƙatun buƙatun yanayin samarwa kuma ana iya amfani da su don haɓaka masana'anta akan layin samarwa.

Kayayyakin OXFAB suna da matukar juriya ga sinadarai da zafi, wanda ke da mahimmanci ga babban aikin sararin samaniya da abubuwan masana'antu. Faɗin gwajin injina yana nuna cewa ana iya amfani da OXFAB don cikakke, shirye-shiryen kayan aiki don bugu na 3D. OPM yana aiwatar da mahimman kwangilar haɓakawa tare da abokan ciniki a cikin sararin samaniya da sassan masana'antu don sassan bugu na 3D don kasuwanci da jirgin sama na soja, sararin samaniya da aikace-aikacen masana'antu, wanda zai iya rage nauyi da tsada sosai.

A yau, fannin masana'antar ƙari ya fashe, kuma wasu na'urori suna ba da damar bugawa akan fiber carbon. Idan masana'antar bugu na 3D tana son samun ƙarin kaso na kasuwa a cikin kasuwar masana'anta na dala biliyan 100, fasahar bugu na 3D yana buƙatar yin amfani da fasahar sarrafawa da kayan aiki. Daban-daban iri-iri na fiber carbon suna nuna yiwuwar wannan burin ya zama gaskiya. Tabbas, don yin gasa tare da masana'anta na gargajiya, kayan haɗin gwiwar sun kasance ɗayan abubuwan da ke haifar da bugun 3D ya zama fasaha ta yau da kullun.

Shiga wannan labarin : Takaitaccen bayanin fasahar buga carbon 3D XNUMXD da aikace-aikacen sa a masana'antar sassan

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

Our Services

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

Case Nazarin

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

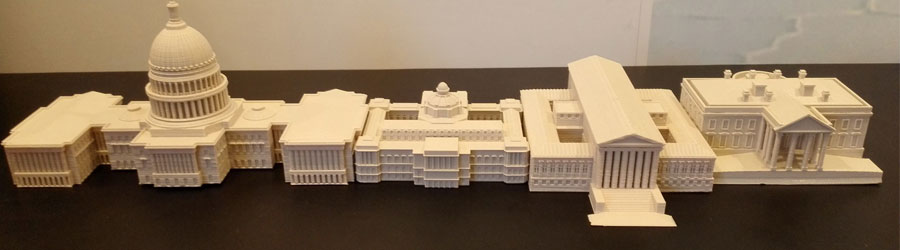

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

Jerin kayan

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan

Bangaren Gallery