Shin magnesium alloy mutu cast simintin gyare-gyare zai iya zama sananne a cikin nauyin nauyi na mota?

2019-09-28

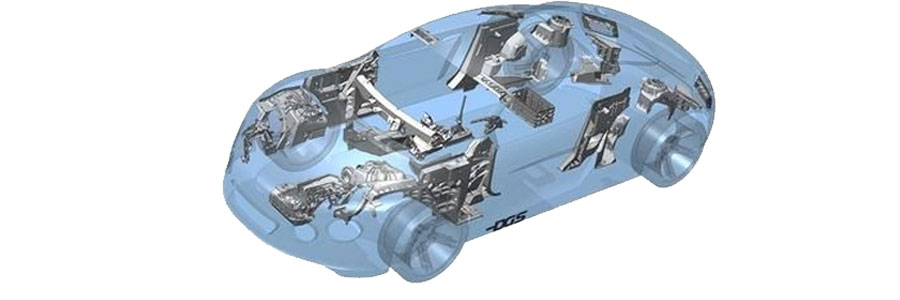

Magnesium gami mutu Fitars zama sananne a cikin mota

| Matsakaicin nauyi na motar shine "siririyar" motar, kuma bisa tushen tabbatar da karko da ingantaccen aiki, ƙirar tanadin makamashi na abubuwa daban-daban da ci gaba da inganta samfurin. Gwajin ya tabbatar da cewa idan nauyin duka abin hawa ya ragu da 10%, za a iya haɓaka haɓakar mai da kashi 6% ~ 8%; an rage nauyin mota da 1%, ana iya rage amfani da mai da kashi 0.7%; ga kowane kilogram 100 na dukkan nauyin motar, za a iya rage amfani da mai a kilomita 100 da 0.3 ~ 0.6. Tashi |

Motoci masu nauyi

Farfesa Ouyang Ming na Jami'ar Tsinghua, a madadin kwamitin ba da shawara kan kiyaye makamashi da sabbin hanyoyin bunkasa makamashi, ya buga abubuwan da ke cikin taswirar fasahar ababen hawa na makamashi. Ra'ayoyin bunkasa fasaha masu nauyi da aka tsara a cikin taswirar hanya ana aiwatar da su ne a matakai uku. Rasa kiba kowace shekara.

Kashi na farko shine daga 2016 zuwa 2020, yana samun raguwar 10% na nauyin abin hawa idan aka kwatanta da 2015. Mayar da hankali kan haɓaka ƙarfe mai ƙarfi mai ƙarfi da fasahar ƙarfe mai ƙarfi mai ƙarfi, gami da haɓaka aikin kayan aiki, hanyoyin ƙira marasa nauyi, ƙirƙirar. fasaha, tsarin walda da hanyoyin kimantawa na gwaji, don cimma ƙarfin ƙarfe mai ƙarfi a cikin aikace-aikacen motoci, ƙimar fiye da 50%, Binciken gami da aluminum karfe stam fasaha da aiki a cikin jiki, nazarin fasahar haɗin kai na kayan daban-daban.

Mataki na biyu shine daga 2021 zuwa 2025, yana samun raguwar 20% na nauyin abin hawa idan aka kwatanta da 2015. Tare da ƙarni na uku na kera motoci da fasahar gami da aluminium a matsayin babban layi, ya fahimci haɗakar abubuwa daban-daban kamar ƙarfe da aluminum. da aikace-aikacen yanki mai fa'ida na duk jikin aluminium don gane yawan samarwa da aikace-aikacen masana'antu na sassan murfin allo da aluminum gami da sassan aluminum. Ƙara haɓakar haɓaka fasahar samar da kayan aikin ƙarfe na ƙarfe na magnesium gami da sassan sassa na fiber fiber, ƙara yawan aikace-aikacen rabon magnesium gami da sassan fiber carbon, kuma ƙarar aluminum don kekuna ya kai 350kg.

Na uku lokaci ne daga 2026 zuwa 2030, cimma wani 35% raguwa a abin hawa nauyi idan aka kwatanta da 2015. Mayar da hankali a kan ci gaban da magnesium gami da carbon fiber hada fasaha, warware matsalar sake amfani da magnesium gami da composite kayan, gane da fadi-- jeri aikace-aikace na carbon fiber hadaddun abu hadawa jiki da carbon fiber sassa, da kuma karya ta hadaddun bangaren kafa fasaha da iri-iri sassa fasahar haɗin gwiwa. Garin magnesium na kekuna ya kai kilogiram 45, kuma amfani da fiber carbon ya kai kashi 5% na nauyin abin hawa.

Bisa kididdigar da aka yi, a shekarar 2016, adadin sinadarin magnesium da ake samarwa a kasar Sin ya kai kilogiram 7.3 kacal, wanda har yanzu bai kai kilogiram 45 na yin amfani da sinadarin magnesium a shekarar 2030 ba. yana da iyaka marar iyaka.

Magnesium gami Properties da abũbuwan amfãni

Ƙananan yawa

Matsakaicin mutu-cast magnesium gami ne kawai 2/3 na aluminum gami, 1/4 na karfe, ƙayyadaddun ƙarfi da ƙayyadaddun taurin sun fi ƙarfe da aluminum gami, da yawa fiye da robobin injiniya, don haka mutu-cast magnesium gami ne wani kyau kwarai a yawancin kayan gini mara nauyi wanda zai iya yin gogayya da abubuwan da ke sama a fagen aikace-aikace.

Kyakkyawan shawar girgiza

Yana da amfani ga raguwar girgizawa da rage amo. Misali, a matakin danniya na 35 MPa, attenuation coefficient na magnesium gami AZ91D shine 25%, kuma na aluminum gami A380 shine kawai 1%. A matakan damuwa na 100MP, magnesium alloys AZ91D, AM60, da AS41 sune 53%, 72%, da 70%, bi da bi, kuma aluminum gami A380 shine kawai 4%.

Babban kwanciyar hankali

Rashin kwanciyar hankali na simintin simintin gyare-gyare na magnesium alloy mutu saboda canje-canje a yanayin zafi da lokaci yana raguwa.

Babban yanayin ɗumamayar zafi

Thermal conductivity na magnesium gami (60-70W / m-1 K-1) ne na biyu kawai ga aluminum gami (kimanin 100-70W m-1 K-1), don haka thermal diffusivity ne mai kyau.

Ba Magnetic ba, ana iya amfani da shi don garkuwar lantarki.

Kyakkyawan juriya na lalacewa

Magnesium alloy kuma yana da kyau damping coefficient. Ƙarfin damping ya fi na aluminum gami da simintin ƙarfe. Ana iya amfani dashi don gidaje don rage hayaniya. Ana iya amfani dashi don kujeru da ƙafafun don rage girgizawa da inganta aminci da kwanciyar hankali na mota. Magnesium gami yana da haske cikin nauyi, mai ƙarfi cikin aikin ɗaukar girgiza, yana da kyau a cikin aikin simintin gyare-gyare, yana da ƙarfin samarwa ta atomatik kuma ya mutu, kuma yana da ƙarfi. A matsayin kayan aikin injiniya mafi sauƙi, magnesium alloy ba kawai kayan da ya fi dacewa don jefa sassa na mota ba, amma har ma mafi kyawun hasken mota. Ƙididdiga kayan aiki.

Matsayin masana'antar simintin gyaran motoci ta magnesium gami

Haɓaka ƙananan nauyi na motoci ya ƙãra buƙatun simintin gyare-gyaren haske kamar magnesium da aluminum. Tun daga 1990, magnesium don motoci yana girma a matsakaicin girma na shekara-shekara na 20%. Magnesium alloys sun zama muhimmin filin ci gaban fasahar kayan aikin mota. Die-simintin simintin gyare-gyaren kayan haɗin gwiwar magnesium sun dace musamman don sake amfani da tattalin arziki, ceton makamashi, ƙarancin carbon da buƙatun samar da tsabta saboda sake yin amfani da su da ƙarancin tsari. Sun mamaye ci gaban motoci zuwa nauyi. Manyan masana'antun kera motoci sun himmatu sun kwaci damar haɓakawa kuma sun saka hannun jari a samarwa da haɓakar simintin gyaran motoci na magnesium gami. Bisa kididdigar da aka yi a cikin "Rahoton Binciken Masana'antu na Magnesium Alloy Automotive Die Casting Industry" a shekarar 2015, bukatun masana'antun sarrafa kayan aikin magnesium na kasar Sin ya kai tan 149,000, wanda ya karu da kashi 23.12%. A halin yanzu, kamfanonin mota na gida da na waje suna aiki a jiki (kimanin 30%), injin (kimanin 18%), tsarin watsawa (kimanin 15%), tsarin tafiya (kimanin 16%), da ƙafafun (kimanin 10%). 5%) Magnesium gami da karfe ko sassan aluminum.

Bisa la'akari da yin amfani da keken magnesium gami da ake samarwa a kasar Sin, karfin kasuwan masana'antar sarrafa motoci ta kasar Sin da ke yin kisa, za ta kai ton 229,000 a shekarar 2017, kuma karfin kasuwar zai kai ton 660,000 nan da shekarar 2022, tare da matsakaicin karuwar adadin kuzari na shekara-shekara. ya kai 23.5%.

Amfani da magnesium a duniya don kekuna ya yi ƙasa sosai, kuma buƙatar faɗaɗa abubuwan haɗin magnesium don motoci yana da ƙarfi. An yi amfani da abubuwa masu nauyi kamar ƙarfe mai ƙarfi, gami da aluminium, da robobin injiniya a fannoni daban-daban na kera motoci da sassa na mota. Magnesium gami ba a inganta ko'ina ba kuma ana amfani da su saboda dalilai daban-daban. Magnesium alloys ana amfani da su a cikin sassan kayan aiki. Bracket, sitiya bracket, kaho, sitiyari, wurin zama, panel na ciki, gidan watsawa, da sauransu. A halin yanzu, kowace mota a Arewacin Amurka tana amfani da 3.8kg na magnesium gami, 9.3kg a Japan, da 14kg na magnesium gami ga kowace mota. A kan PASSAT na Turai da Audi A4, yayin da matsakaicin yawan motocin Sinawa ya kai kilogiram 1.5 a kowace mota.

Aikace-aikace na magnesium gami a cikin ƙananan nauyi na mota

magnesium alloy mutu simintin sassa

Tsarin ciki na motaKo da yake alluran magnesium suna da ƙarancin juriya na lalata, kariyar lalata ba babban abin la'akari ba ne don ginin ciki na mota. Sabili da haka, an yi amfani da alluran magnesium sosai a cikin gine-ginen cikin gida na motoci, musamman a cikin sassan kayan aiki da tsarin tuƙi. An ba da rahoton cewa ginshiƙin kayan aikin kayan aikin magnesium na farko ya mutu ta hanyar General Motors a cikin 1961, yana adana kilogiram 4 na abu idan aka kwatanta da sassan da aka samar da simintin simintin ƙarfe na zinc alloy. A cikin shekaru goma da suka gabata ko makamancin haka, amfani da ginshiƙan tire na kayan aikin da ake amfani da su na magnesium gami ya sami babban ci gaba.

Aiwatar da kayan aikin magnesium a cikin wurin zama ya fara ne a Jamus a cikin 1990s, galibi a cikin SL Roadster ta amfani da tsarin bel ɗin kujera mai maki uku wanda aka yi da simintin simintin ƙarfe na magnesium. Hakazalika da aikace-aikace na magnesium alloy a kan kayan aiki na kayan aiki, a cikin 'yan shekarun nan, zane da kuma samar da kujerun da aka yi da kayan aikin magnesium sun sami gagarumin cigaba. Tsarin wurin zama tare da gami da magnesium na iya zama bakin ciki kamar 2mm, wanda ke rage nauyi sosai. Ko da yake ana amfani da wasu kayan kamar ƙarfe mai ƙarfi, aluminum, da kayan haɗin gwiwa, masana sun yi hasashen cewa abubuwan haɗin gwiwar magnesium za su zama babban kayan da za a yi amfani da su don yin nauyi mai sauƙi da tsadar kayan aikin motar mota a nan gaba.

Jikin Kai

Magnesium alloys suna iyakance a aikace-aikacen jiki, amma kuma ana amfani da su a cikin OEMs. Lokacin da Janar Motors ya gabatar da C-5 Corvette a cikin 1997, ya yi amfani da firam ɗin rufin da aka yi da simintin simintin gyare-gyare na magnesium alloy cikakke. Bugu da kari, an kuma yi amfani da gami da magnesium a cikin rufin mai iya juyawa mai wuyar iya jurewa da babban firam na Cadillac XLR Convertible. Ford F Motar -150 da SUV suma suna amfani da simintin simintin gyare-gyare na magnesium a matsayin madaidaicin kwandon zafi. A Turai, Volkswagen da Mercedes-Benz ne suka jagoranci yin amfani da simintin simintin simintin simintin gyare-gyare na magnesium a cikin sassan jiki.

shasi

A halin yanzu, an yi amfani da simintin simintin gyare-gyare ko gyare-gyare a cikin manyan motocin tsere masu tsada ko manyan motocin wasanni. Koyaya, in mun gwada da tsada mai tsada da yuwuwar matsalolin lalata na ƙafafun magnesium gami suna hana amfani da su a cikin manyan motocin samarwa.

A nan gaba, samar da nau'o'in nau'i mai sauƙi, ƙananan farashi na magnesium alloy chassis, irin su cibiyoyi, dakatarwar injiniya da kuma kula da makamai, za su dogara sosai kan tsarin simintin simintin gyaran gyare-gyare na magnesium, kuma an ƙera su akan ƙafafun aluminum gami da kayan aikin chassis. Za'a iya samun nasarar amfani da tsarin simintin simintin gyare-gyare zuwa ga ma'aunin magnesium bayan gyare-gyare. Bugu da ƙari, ci gaba da ƙananan farashi, ƙananan yadudduka masu lalata da kuma sababbin abubuwan haɗin gwiwar magnesium tare da gajiya da ƙarfin tasiri mai karfi zai hanzarta yin amfani da kayan aikin magnesium akan chassis.

Powertrain

Yawancin simintin gyare-gyaren na'urar wutar lantarki, kamar injin toshe, shugaban silinda, harka watsawa, kwanon mai, da dai sauransu, an yi su ne da gami da aluminum. A halin yanzu, manyan motocin daukar kaya da SUVs da aka kera a Arewacin Amurka sun kasance isar da sako na sinadarin magnesium, haka nan kuma ana samar da na'urorin na Volkswagen da na Audi na magnesium gami a kasashen Turai da China.

A halin yanzu, an sami ci gaba mai inganci ta hanyar gwaje-gwajen dynamometer akan samfuran injunan haɓakar injunan magnesium, wanda ke nufin za a yi amfani da ƙarin gami da magnesium a tsarin wutar lantarki a nan gaba.

Babban ƙalubale a cikin haɓakawa da aikace-aikacen kayan aikin magnesium

Rashin juriya na lalata, tsada mai tsada da yawan tarkace sune mashahuran shinge ga gami da magnesium.

Alloys na Magnesium ba su da matsalolin tsadar tsadar simintin ɗimbin ɗimbin ɗimbin ɗimbin ɗimbin ɗimbin yawa, da ɓoyayyun haɗarin samar da lafiya. Du Fangci, mai ba da shawara ga kungiyar masu kera motoci ta kasar Sin, ya bayyana cewa, sinadarin magnesium wani sinadari ne mai matukar aiki, kuma juriyar lalatarsa ba ta da kyau sosai. Ƙarfin fasaha na kasar Sin a cikin juriya na juriya na sassan ƙarfe na magnesium ya fi muni. Bugu da ƙari, magnesium yana da sauƙi ga konewa da fashewa yayin aiki, kuma akwai matsalolin samar da tsaro. Wuraren samarwa suna buƙatar kulawa mai ƙarfi don tabbatar da samar da lafiya.

Tare da haɓaka birane, makamashi yana ƙara yin karanci, gurɓataccen muhalli yana ƙara tsananta, kuma kiyaye makamashi da rage fitar da hayaki ya zama wani muhimmin al'amura da suka shafi tattalin arzikin ƙasa da rayuwar jama'a. Dukansu motocin gargajiya da sabbin motocin makamashi masu tasowa suna ba da kulawa sosai ga ƙirar jikin mara nauyi don cimma nasarar ceton makamashi da kariyar muhalli.

Magnesium alloys na motoci suna haɓaka, kuma tsarin simintin simintin simintin simintin gyare-gyare na magnesium yana ƙara girma, kuma kewayon aikace-aikacen yana faɗaɗa. Manyan ɓangarorin mota na simintin simintin simintin gyare-gyare na magnesium gami za su haɓaka aikin ɗaukar nauyi na mota.

Shiga wannan labarin : Shin magnesium alloy mutu cast simintin gyare-gyare zai iya zama sananne a cikin nauyin nauyi na mota?

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

Our Services

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

Case Nazarin

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

Jerin kayan

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan

Bangaren Gallery