Waɗanne hanyoyi ne ake amfani da samfurin ƙirar filastik?

Samfurin Samfurin Samfurin Plastics

| Kayan aikin samfuri na iya nuna ƙirar mai kerawa sosai. Kamar tsarin, bayyanar Prototype, da sauransu, samfurin samfuri yana ba da damar tallata sassan an taƙaita sosai, ƙirarta tana gaba-gaba, kafin ƙirar ta haɓaka, zaku iya amfani da samfurin don mall inganta, ɗauki jagoranci, kuma a farkon sayarwa, Shirya don samarwa da mamaye kasuwa da wuri. |

Mataki na farko:

bisa ga abokin ciniki don samar da nazarin bayanan 3D don ƙayyade fasahar sarrafawa, don ƙayyade fasahar sarrafawa don sarrafa CNC;Mataki na biyu: sarrafa bayanai:

- 1) Dangane da halayen fasahar sarrafa samfurin filastik, akwai nau'uka biyu: daya shine bayanan da za'a iya sarrafa su kai tsaye; ɗayan shine buƙatar amfani da software na CAD, software na proe ko ug software don raba cikin bayanan sarrafawa;

- 2) Akwai makircin sarrafa abubuwa iri biyu. Isaya shine yin aikin sarrafa ruwa a cikin bayanan. Lokacin shirye-shirye, zana dutsen da ke kusa da samfurin filastik tare da radius na kusan 1 mm ko fiye don raba aikin sarrafa A ko B, wanda zai ɗaga saman. Ana amfani da 0.5-0.8 mm don gyara haɗin tsakanin samfurin filastik da blank, sa'annan kuma duk aikin ya ƙare sannan milled off. Wannan maganin yana amfani da wuka mai leda ko wuka mai ƙare don buɗe lokacin farin ciki; ɗayan shine yin aikin sarrafa ƙasa na taimako. Wannan samfurin filastik an karɓa. Ball wuka sarrafa wuka;

- 3) Bayan an sarrafa bayanan zuwa yanayin sarrafa su kai tsaye, ya zama dole a yi amfani da masarrafan sarrafa kwamfuta ta hanyar kwamfuta wajen aiwatarwa;

- 4) Softwares din guda biyu wadanda aka tsara sune Mastercam 9.1 da WorkNC 16.21, wadanda ake amfani dasu wajen rubutawa da rubuta shirye-shiryen 2D; ana amfani da WorkNC 16.21 don ƙididdige hadaddun wurare; ana amfani da software ta Mastercam 9.1 don tsarawa da rubuta shirye-shiryen 2D. Ko kuma shirye-shiryen shirin aikin inji na 3D, kuma amfani da umarnin "contour shape" a cikin software ta Mastercam9.1 don samar da layin iyaka na aikin, kuma yi amfani da wannan layin don samar da jirgin sama azaman iyakar iyaka mai taimakawa a cikin software na WorkNC 16.21;

- 5) Shirye-shirye don farfajiyar taimako yayin shirye-shirye: Yi amfani da software na Mastercam9.1 don yin shimfidar ƙasa mai sauya tsarin IGES tare da software na WorkNC 16.21 don shirye-shirye. Wannan maganin ya zama daidai da kayan aikin A ko B;

- 6) Kada a shirya farfajiyar taimako yayin shirye-shirye: Yi amfani da software ta Mastercam9.1 don rubuta wuka mai faɗi a buɗe hanya mara kyau, daidaiton iyakar iyaka: radius na kayan aiki + buɗe keɓewa + 0.15 mm; babu wata hanyar taimako da aka sauya daga tsarin IGES kusa da bayanan. An tsara shi tare da software na WorkNC 16.21; a wannan lokacin, kayan aikin ɓarnatarwa na B sun fi ƙananan kayan aikin A-side, ko na 1 ko A'a. 2, don kauce wa amfani da A-side a matsayin tsayayyen sandar PVC da za a huɗa da an goge samfurin roba;

- 7) Shirya shirye-shirye da kuma rubuta fitar hanya zuwa sashen ma'aikaci, da kuma tura shirin zuwa mashin din;

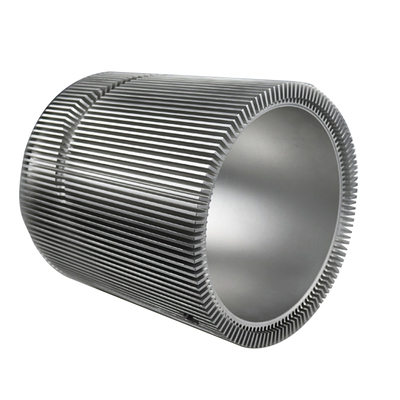

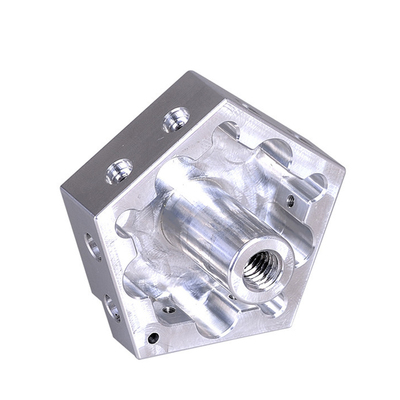

Mataki na uku: Cibiyar CNC

- 1) Bayan sashen mashin din ya karbi odar aikin, sai yayi nazari akanshi. Bayan an kammala nazarin, ana shirya inji da ma'aikata, kuma ana yiwa kayan alama bisa ga tsarin aiki.

- 2) Hanyar gyarawa ta inji tana ɗaukar aikin manne katako ko manne AB, kuma an ƙarfafa shi da ƙaramin ABS ko sandar PVC kewaye da blank. Hanyar sanyawa tana amfani da hanyar fil ɗin sakawa, kuma an sanya fil ɗin sakawa tare da sandar ABS da aka gama ta 6.0 ko 8.0 mm;

- 3) Samfuran filastik waɗanda ke buƙatar ɓangarorin biyu na A da B: Gefen A: Ana sarrafa farfajiyar A ta hanyar yanke ruwa + sanyaya iska mai sanyi, kuma ana yin shirye -shiryen azaman mai taimako. Bayan an kammala aikin A surface, yankin tsarin ƙirar filastik yana buƙatar haɗewa tare da m narkewa mai ƙarfi don ƙarfafa shingen ABS, wanda ya fi gaban ƙarshen gefen A mara fa'ida. Milling, don ta iya taka rawar tallafawa mai kyau yayin sarrafa fuskar B, rage rawar da injin ke samarwa. Idan ba a yi amfani da farfajiya mai taimako ba, yakamata a haɗa sandar PVC tare da manne mai ɗumi-ɗumi a kusa don gyara samfurin filastik da faranti. Bayan kammala aikin A-fuska, ɓangaren da ke cike ya cika da gypsum don hana girgiza yayin da ake sarrafa B-fuska; Gefen B: An sanya saman B ɗin ta wurin matattarar matsayi, an rufe ƙasa da ruwa mai ninki biyu- tef mai gefe kuma kewaye da manne na katako; idan aka sarrafa shi, iska mai matsewa yake sanyaya shi; bayan an gama shimfida shimfidar B, yana buƙatar aiki da kyaftin ɗin da mai shirye -shirye don tabbatar da cewa babu matsala sannan za a iya kora injin;

- 4) Fuskoki biyu na samfurin filastik ba za a iya sarrafa su gaba ɗaya a wuri ba, kuma ya zama dole a bi mashin ɗin. Wajibi ne a tsara jig ɗin taimako sannan a gama aikin inji a kan inji;

- 5) Muddin ana sarrafa samfurin roba ta fuska daya, kasan blank din ana sarrafa shi kwance kuma ana amfani da tef mai ruwa mai ruwa biyu don kammala aikin;

- 6) Ga wasu sassan samar da kayan masarufi, ana bukatar gyara, kuma aikin gyaran ya kammala ta hanyar tsara mataimaki maras motsi;

- 7) Don hana nakasawa yayin aiwatar da samfurin filastik, ya zama dole ayi gasa a cikin tanda a gaba don sakin damuwar nakasa: ABS abu, ana buƙatar gasa shi a digiri 80 na awanni 4, da ƙofar tanda ba a sanyaya ta ɗabi'a a cikin tanda; Kayan PC: buƙatar yin burodi na digiri 100 Gasa na awanni 6, kar a buɗe ƙofar tanda don yin sanyi ta ɗabi'a a cikin tanda; Kayan POM: buƙatar yin gasa na awanni 8 na awanni 8, kar a buɗe ƙofar tanda don yin sanyi ta ɗabi'a a cikin tanda;

Mataki na hudu: posting machining

Bayan jiyya, kuna buƙatar samun samfuran da aka gama bayan NC ya ƙare, sannan ku tsabtace filastar da ruwa, sa'annan ku cire manne mai narkewa mai zafi da barasa, cire tabon mai da sauran tarkace tare da mai, kuma ku bushe murhun na mintina 45 da mintuna 20 don duba yawa da girman. Siffa da kayan aiki, bayan tabbatar da kuskuren, cire burrs ɗin kuma cire matattun kusurwoyin, da kuma fantsama tare da manne ko dichloromethane m;

The surface jiyya na sashin aikin bayan gida kamar haka:

- 1) Takardar sandar an goge da hannu, kuma an yanke sandar a sandar sandwich mai fadin kusan 150 * 40 mm, kuma anyi sanded da irin wannan kwano irin na silinon, odar tana daga mara kyau zuwa kyau;

- 2) Gogewa, PMMA mai haske tana bukatar yashi daga mara nauyi zuwa mai kyau zuwa 2000 # sandpaper, sannan a goge shi da 3M kakin goge da goge zane ko inji mai gogewa;

- 3) Rini, sassan da suke bukatar a rina Bayan goge su, sai a zuba rina a cikin bakin karfe na bakin karfe sannan a dumama shi zuwa digiri 60-80, sai a sanya sassan a jika na mintina 5-10 su fita, rina ka iya zama kammala;

- 4) Bayan an yi feshi, bayan an hade samfurin roba, a goge shi da lambar share fenti mai lamba ta 320, sannan a yi sandar da shi zuwa sandar sandar 800 ko sandar sandar 1000 don fesa fenti;

- 5) Electroplating, electroplating ne aluminized da Chrome-plated. Aikin fadakarwa shine yankan fanko. Yana buƙatar fesawa zuwa 600 # sandpaper. Tsarin saka chrome shine plating na ruwa. Ana buƙatar goge shi zuwa sandpaper na 2000 sannan a goge don zaɓan lantarki. Za'a iya cire sassan aluminin da aka zana su, kuma za'ayi aikin chrom-plated ba za'a iya cire shi ba, kuma za'a iya sarrafa shi gaba daya;

- 6) Gaskiya da gaskiya. Ana amfani da wannan hanyar don goge kai tsaye. Hakanan an goge sassan PC ɗin zuwa takarda mai sandar grit 1000 sannan kuma an haske su da dichloromethane.

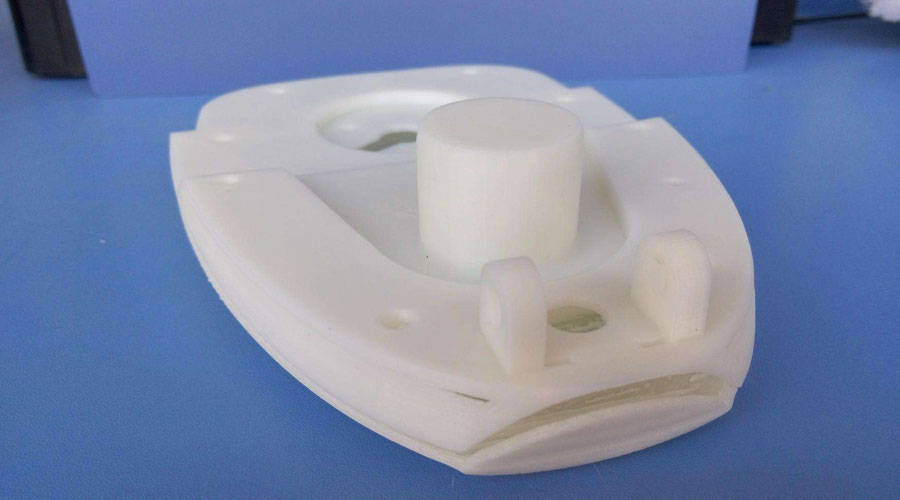

Mataki na biyar: aikin gyaran siliki

Yi samfuri ta amfani da CNC kuma yi amfani da wannan samfurin don yin ƙirar silicone.

Shiga wannan labarin : Waɗanne hanyoyi ne ake amfani da samfurin ƙirar filastik?

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis masu saurin daidaitaccen kayan aikin CNC ciki har da niƙa, juyawa zuwa ƙayyadadden abokin ciniki, Caparfin ƙarfe & kayan aikin filastik tare da haƙurin +/- 0.005 mm.mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis masu saurin daidaitaccen kayan aikin CNC ciki har da niƙa, juyawa zuwa ƙayyadadden abokin ciniki, Caparfin ƙarfe & kayan aikin filastik tare da haƙurin +/- 0.005 mm.mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan