Hanyar inganta machining machining na shaft gear hobbing

Binciken daidaiton machining na shasha kaya sha'awa

| Ta hanyar nazarin daidaito na gyaran inji na shaft gear, an gano abubuwan da suka shafi daidaito na aikin hobbing, ta yadda za a inganta ingancin aikin hobbing. |

Gilashin shaft shine mafi mahimmancin sashi a cikin akwatin gear, kuma daidaiton mashin ɗinsa yana shafar ingancin akwatin gear kai tsaye. A halin yanzu, hanyar sarrafa haƙoran gear da muke amfani da su ita ce hanyar hobbing da aski. Don samar da ingantattun kayan aiki ta hanyar mirgina da aski, ya zama dole don haɓaka matakin mirgina da aski. Daidaiton aski ya dogara da daidaiton sirdi na hobbing, don haka dole ne a sarrafa wasu kurakurai a cikin hobbing don samar da kayan aiki masu inganci. Hobbing hanya ce ta sarrafa kaya da aka saba amfani da ita.

A kan babban na'urar hobbing, ana iya amfani da hob ɗin madaidaicin don injin gear hakora tare da daidaici 4-5. A kan na'urar hobing na yau da kullun, hakoran madaidaicin gear guda 8 ne kawai za a iya yin injin tare da daidaitaccen hob na yau da kullun. Daidaiton haƙoran gear shaft gear shine 8-7-7, kuma tsarin hobbing ya dogara ne akan ramukan tsakiya guda biyu da fuskar ƙarshen. Sabili da haka, ana nazarin tushen kuskuren hobbing, kuma an ƙware hanyar tabbatarwa da inganta daidaiton mashin ɗin. Muhimmanci sosai.

Daidaiton haƙoran haƙora yana da alaƙa da daidaiton motsi, daidaiton tsayin daka, da daidaiton lamba. Sarrafa tsawon layin gama gari na gama gari da diamita na kayan zobe a cikin aikin hobbing

Don tabbatar da daidaiton motsi, ana amfani da kuskuren bayanin martabar haƙori mai sarrafawa da ɓacin ɓangaren tushe don tabbatar da sassaucin aikin, kuma ana sarrafa kuskuren haƙori don tabbatar da daidaiton lamba. Mai zuwa shine nazarin dalilan kurakurai da yawa waɗanda ke da alaƙa da hobbing:

1. Kuskuren runout gear gear radial (watau eccentricity geometric)

Ring gear gear radial runout yana nufin matsakaicin bambancin binciken dangane da haƙoran haƙora a cikin kewayon kayan aiki, binciken yana cikin tsagi na haƙori ko akan haƙoran gear, kuma yana cikin hulɗa da tsakiyar tsayin haƙori. Hakanan shine eccentricity na zoben gear dangane da layin tsakiya na shaft. Wannan eccentricity yana haifar da gaskiyar cewa ramukan tsakiya guda biyu na ɓangaren ba su daidaita ko karkatar da yawa daga tsakiyar juyawa na tebur lokacin da aka ɗora sassan. Ko kuma saboda ƙarancin masana'anta na saman da ramuka na sama, ba a tuntuɓar mahaɗin da ke da kyau ba, wanda ke haifar da eccentricity, don haka ya kamata a warware mafi girman girman girman zobe daga dalilan da ke sama.

2. Kuskuren tsayi na yau da kullun (watau eccentricity motsi)

Hobbing shine a yi amfani da ƙa'idar hanyar ƙirƙira don injin kayan aikin. Sarkar watsa kayan aiki daga kayan aiki zuwa haƙoran haƙora ya kamata su kula da daidaiton motsi bisa ga wani nau'in watsawa. Amma waɗannan sarƙoƙi na tuƙi an yi su ne da jerin abubuwan watsawa.

Kuskuren masana'anta da taro dole ne a mayar da hankali kan sassan ƙarshen sassan watsawa yayin motsi na watsawa, wanda ke haifar da rashin daidaituwa na motsin dangi da kuma shafar daidaiton mashin ɗin na hakora. Canjin tsayin layin al'ada na gama gari shine matsakaicin kuskure wanda ke nuna rashin daidaituwa na rarraba hakora.

Wannan kuskuren yana faruwa ne saboda rashin daidaiton jujjuyawar daidaiton tebur gear na injin hobbing, da kuma da'irar jagorar layin dogo na tebur na hobbing, dabaran tsutsa mai nuni da jagorar madauwari na tebur. Sakamakon gatari daban-daban, ban da haka, akwai ƙwanƙwasawa mai tsanani a saman haƙorin da aka raba kayan aikin da sako-sako ko kuma matsatsin cizon motar rataye kuma zai shafi bambancin al'ada na yau da kullun.

3. Binciken kuskuren siffar haƙori

Kuskuren siffar haƙori yana nufin tazara ta al'ada tsakanin madaidaitan bayanan haƙori guda biyu (involute) waɗanda ke ɗaukar ainihin bayanan haƙori a cikin sashin aikin haƙori.

Ba shi yiwuwa a sami cikakkiyar madaidaicin bayanin martaba a zahiri aiwatar da aiki, kuma koyaushe akwai kurakurai daban-daban, wanda hakan ke shafar sauƙin watsawa. Da'irar tushe na kayan aiki shine kawai siga da ke ƙayyade sifar haƙori mai ƙima. Idan da'irar tushe ta haifar da kuskure yayin aikin hobbing, yanayin haƙori kuma dole ne ya sami kurakurai. Base da'irar radius R = Gudun motsi / tebur yana kashe saurin kusurwa xcosao (ao shine ainihin kusurwar hakori na hob).

Yayin aiwatar da hobbing, sifar haƙori mai ƙima ana tabbatar da shi ta hanyar kiyaye ƙayyadaddun ƙimar saurin gudu tsakanin hob da sarari. Ana iya ganin kuskuren bayanin martabar haƙori an ƙaddara shi ne ta hanyar kuskuren siffar haƙori, kuma ingancin niƙa na hob ɗin ba shi da kyau kuma kuskuren bayanin martabar haƙori yana da sauƙin faruwa. A lokaci guda, radial runout da axial turbulence (watau kuskuren shigarwa) wanda hob ya haifar yayin shigarwa kuma yana da tasiri akan kuskuren bayanin martaba na hakori. Kuskuren siffar haƙori na gama gari sune asymmetrical, kuskuren kusurwar hakori (saman haƙori ko kauri), kuskuren zagayowar, da sauransu.

4. Binciken kuskuren shugabanci na hakori

Kuskuren hakori shine ƙarshen fuska tazarar layukan haƙoran ƙira guda biyu waɗanda ke ɗaukar ainihin layin haƙori a cikin kewayon cikakken faɗin hakori akan saman silinda mai nuni. Babban abin da ke haifar da rashin daidaituwar hakori shi ne cewa madaidaiciyar hanyar ciyar da kayan aikin injin da mai riƙe kayan aiki an kashe shi daga axis na ɓangaren, ko kuma tsakiyar ƙarshen saman wutsiya bai dace da tsakiyar juyawa na tebur ba. , da kuma kuskuren lissafi na dabaran rataye daban-daban lokacin mirgina kayan aikin helical Manyan masana'anta na sarkar tuƙi da kurakurai masu daidaitawa sun yi girma. Bugu da ƙari, daidaito na masana'anta, shigarwa da daidaitawa na jig da blank kuma na iya haifar da kuskuren hakori.5. Binciken rashin haƙora

Akwai al'amura da dama a cikin haƙorin haƙora: layin gashi, caries, phosphorus kifi, hawaye.

Babban abubuwan da ke haifar da bambance-bambance a cikin haƙoran haƙora sune kamar haka: gabaɗayan rigidity na kayan aikin injin, kayan aiki da tsarin aikin aiki bai isa ba, rata yana da girma; Matsayin dangi na hob da aikin aikin ya canza; hob din ba shi da ƙasa sosai, kayan aikin ɓangaren ba daidai ba ne; Ba a zaɓi sigogin yankan ba. Dace

Shiga wannan labarin : Hanyar inganta machining machining na shaft gear hobbing

Bayanin Bugawa: Idan babu umarni na musamman, duk labaran da ke wannan rukunin yanar gizon asali ne. Da fatan za a nuna tushen don sake bugawa: https: //www.cncmachiningptj.com/,thanks!

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

PTJ® yana ba da cikakken kewayon Custom daidaici cnc machina china sabis. ISO 9001: 2015 & AS-9100 bokan. 3, 4 da 5-axis saurin daidaito Cibiyar CNC ayyuka ciki har da niƙa, juyawa ga takamaiman kwastomomi, Caparfin ƙarfe & kayan aikin roba tare da haƙuri +/- 0.005 mm.Sakarantun sakandare sun haɗa da CNC da nika na al'ada, hakowa,mutu Fitar,karfe da kuma stam.Yawan samfoti, cikakken kayan aiki, tallafi na fasaha da cikakken dubawa mota, jirgin sama mai saukar ungulu, gyare-gyare & tsayarwa, jagoran haske,likita, keke, da mabukaci kayan lantarki masana'antu. Isarwar lokacin-lokaci.Ka gaya mana kadan game da kasafin kudin aikin ku da lokacin isowar sa ran ku. Zamu tsara tare da ku don samar da ayyuka mafi tsada don taimaka muku don isa ga burin ku, Maraba da Tuntube mu ( sales@pintejin.com ) kai tsaye don sabon aikin ku.

- 5 axis machining

- CNC Milling

- Cnc Juyawa

- Masana'antar Mashin

- Tsarin Machining

- Kula da Surface

- Karfe Machines

- Injin roba

- Foda Metallurgy Mould

- Mutuwar Castauki

- Bangaren Gallery

- Kayan Karfe

- Kayan na'urorin

- Kayan Wuta

- Ginin Gine-gine

- Sassan Wayoyin hannu

- Bangaren Likita

- Kayan lantarki

- Kera machining

- Kayan Bicycle

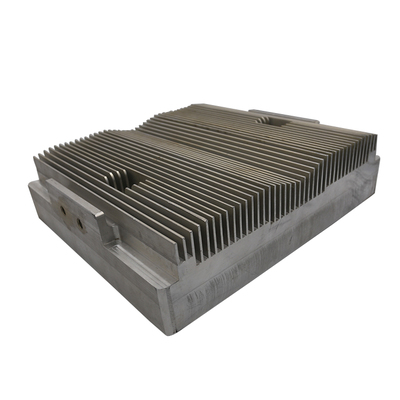

- Gilashin Aluminum

- Titanium Machining

- Bakin Karfe Machining

- Na'urar Karfe

- Na'urar Karfe

- Super Alloy Machining

- Gwanin Peek

- Farashin UHMW

- Keɓaɓɓen Kera

- Farashin PA6

- Injin PPS

- Teflon Machining

- Inconel Injin

- Tool Karfe machining

- Ƙarin Abubuwan